Split Type

Contents

Way Air Discharge Cassette Type

Indoor Unit

Current

Operation characteristic curve Cooling Heating

RAV-SM560BT-E RAV-SM800BT-E

Concealed Duct Type

RAV-SM800BT-E

RAV-SM560KRT-E RAV-SM800KRT-E

High-Wall Type

RAV-SM800KRT-E

RAV-SM560XT-E RAV-SM800XT-E

Flexible Type

RAV-SM800XT-E

Outdoor Unit

AIR Ducting Work

Construction Views External Views

RAV-SM560BT-E

RAV-SM800BT-E

High-Wall Type RAV-SM560KRT-E/RAV-SM800KRT-E

RAV-SM560XT-E/RAV-SM800XT-E

RAV-SM560AT-E

RAV-SM800AT-E

Systematic Refrigerating Cycle Diagram

RAV-SM800UT-E, RAV-SM800BT-E, RAV-SM800KRT-E/RAV-SM800AT-E

MCC-1402

RAV-SM560BT-E/RAV-SM800BT-E

MCC-1370A

Simple Check Points for Diagnosing Faults

RAV-SM560AT-E

Board

Specifications of Electrical Parts

Accessory Separate Sold Parts

Refrigerant R410A

Processing of Piping Materials

1 Flare processing dimensions

2 Relations between flare nut and flare seal surface

Tools

Recharging of Refrigerant

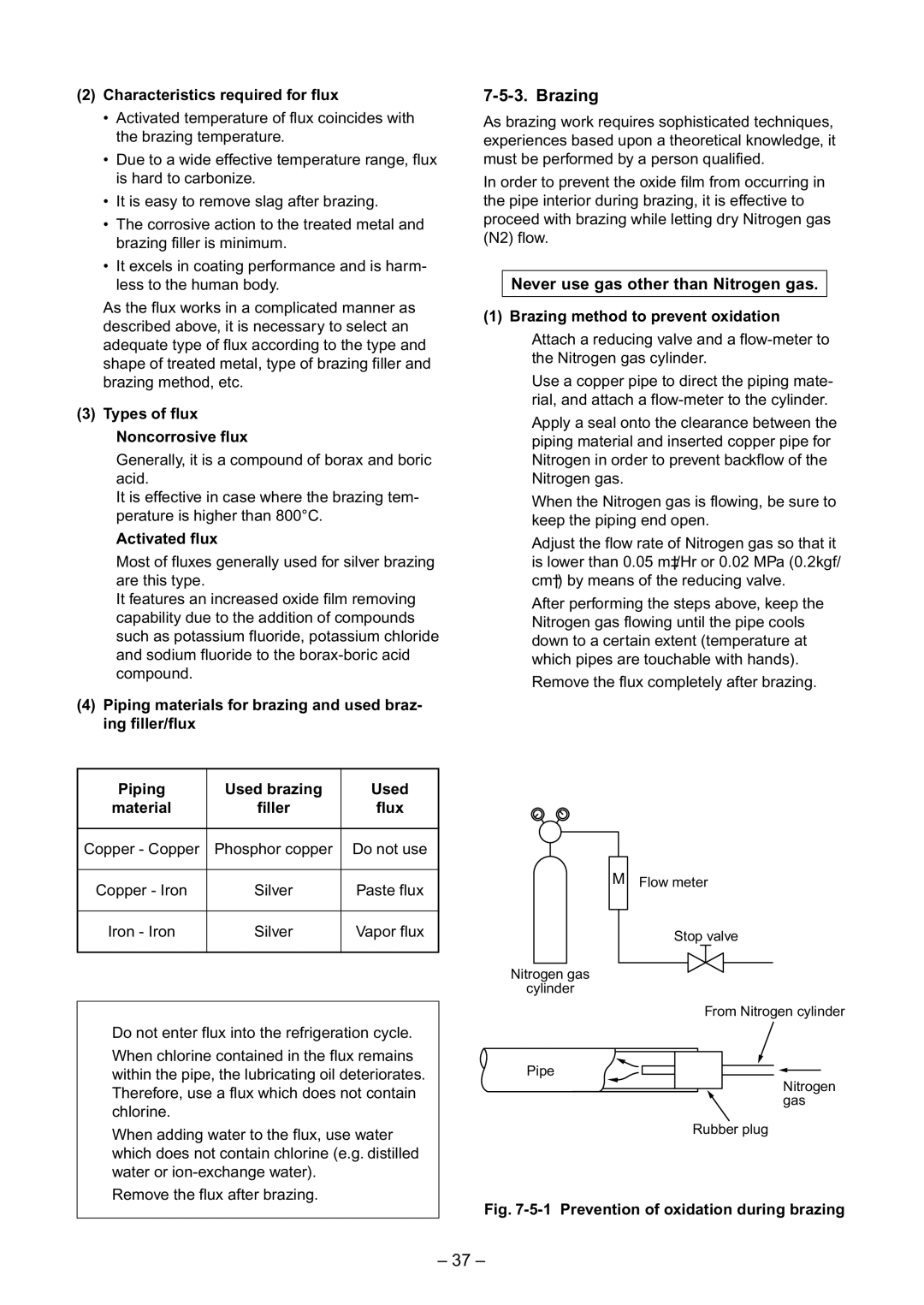

Brazing of Pipes

Brazing

Indoor Control Circuit

Main Sub master remote controller

Indoor unit

Outline of specifications Remarks

Control Specifications

Remote controller Outline of control Command

Operation

Heating Auto

Standard High ceiling SM560

Operation of duct only

Control temp C

All modes

Cooling/dry operation In heating/fan operation

Frequency fixed In case of wired remote controller

Center

Last push priority

Operation Prohibited

MCC-1402

Indoor Print Circuit Board

Way Air Discharge Cassette Type RAV-SM560UT-E/RAV-SM800UT-E

Concealed Duct Type

MCC-1403

Connection of Main Remote Controller

Microcomputer System Block Diagram

Main Sub master remote controller

Indoor unit

Connection of Wireless Remote Controller

Heating operation

Control Specifications

Tc Temperature of indoor

Air volume setup SM560 SM800

Outline of specifications

Remarks

Tc C

Cool L

Figure if To 15C

Main P.C. board MCC-1370A Sub P.C. board MCC-1370B

Print Circuit Board

Outline of Main Controls

Discharge temperature release control

Pulse Modulating Valve PMV control

Current release control

Function Connector Pin Specifications Remarks

Indoor P.C. Board Optional Connector Specifications

MCC-1398 RAV-SM560AT-E Viewed from parts of P.C board

Outdoor Controls

MCC-813 RAV-SM800AT-E

MAX

Allocations of fan tap revolutions

Outdoor fan control Object SM560

Cooling operation

Heating operation

High-voltage suppression TE control Only for SM800

Short intermittent operation preventive control

Over-current preventive control

Current release value shift control

Start of heating operation

Defrost control

SM560 SM800

Wired remote controller type

Summary of Troubleshooting

Before troubleshooting

Trouble

Troubleshooting procedure

Error mode detected by indoor unit

Check Code List

Diagnostic function Cause of operation

Error mode detected by outdoor unit

Timer Ready Wired remote Controller Check code

Error mode detected by remote controller or network adapter

SW800 LED display in bit 1, bit 2, bit 3 OFF

Error Mode Detected by LED on Outdoor P.C. Board

Check code

Type a

E01 error/*99 error

Troubleshooting Procedure for Each Check Code

E09 error/*99 error

New Check Code/Present Check Code Central Control Side

E04 error/04 error

E08, L03, L07, L08 error/ *96 error 99 error

E18 error/97 error *99 error

L09 error/46 error

L30 error/B6 error

L20 error/98 error

B7 error Central controller

F10 error 0C error

P10 error/Ob error

CN333

Single phase

P22 error/1A error

F02 error/0d error

P19 error/08 error

P26 error/14 error

F01 error/0F error

H03 error/17 error

P29 error/16 error

F04 error/19 error

F06 error/18 error

F08 error/1b error

H02 error/1d error

L29 error/1C error

H01 error/1F error

P03 error/1E error

P04 error/21 error

Same as others Correct connection of connector

Error Central controller

F29 error / 12 error

E03 error Master indoor unit

P31 error Sub indoor unit

Caracteristics-3

TA sensor Caracteristics-1

TC, TCJ sensor Caracteristics-2

20 TE, TO, TS sensor

Case

R2 Replacement of service P.C. board

R1 Readout of the setup data from Eeprom

Contents

Minimum requirements for item code

R3 Writing of the setup contents to Eeprom

Type Item code

Memorandum for setup contents Item code table Example

Indoor unit capacity Item code

Wired remote controller

Test Run Setup on Remote Controller

Procedure Use this function while the indoor unit stops

Setup to Select Function

Push SET , , and buttons concurrently for 4 seconds or more

Pushing button returns the status to usual stop status

Description At shipment

Item No. DN table Selection of function

Setup method

Cabling and Setting of Remote Controller Control

Wireless remote controller

Operation

Contents

Monitor Function of Remote Controller Switch

Procedure

Group control operation

Calling of error history

Requirement

System example

Network Address Setup Switch SW01

Microcomputer Block Diagram

LED Display Specification

Network Adapter

Communication circuit Communication cable specifications

Communication Cable Specifications

Cable Connection

Network cable connection

How to set from the remote controller at indoor unit side

How to Set an Address Number

How to set by the switch on the network adapter P.C. board

Procedure Set the network address while the unit stops

Network address No. setup table SW01

Requirement in Service

101

Address No

102

Contents

Address setup procedure

Address Setup

103

System configuration

Address Setup & Group Control

Only turning on source power supply Automatic completion

Automatic address example from unset address No miscabling

105

Manual setting from remote controller

Push button if the unit stops

106

To know the position of indoor unit body by address

Push and buttons simultaneously for 4 seconds or more

107

RAV-SM800AT-E LED display when SW800 Bit 1, 2, 3, 4 OFF

Table a

Check code LED display Type D800 D801 D802 D803 Red Yellow

108

Troubleshooting Wall Type

Self-diagnosis by check code on the remote controller

Wireless remote controller type

109

Outline of Judgment

110

Self-diagnosis with remote controller

How to select remote control operation mode

111

Self-diagnosis by check codes

112

Operating key Indication after operation

Example

Reset switch

Troubleshooting with Check Display of Remote Controller

Check switch

Case of main remote controller/sub-remote controller a

Display on Check monitor

Segment display

Filter data

Check data

Check switch

Remote controller with timer RBC-AM1E

Reset switch

LCD display Standby is present

116

Data

Check switch

Central remote controller

Reset switch

117

118

Check Code Table

Conditioner

119

Ipdu

120

1A error

Troubleshooting for Each Check Code

121

122

Error

123

0C error

0F error

0d error

124

125

YES

126

Board CN210 Blue Yellow White Black Red

127

128

129

1C error * Except RAV-SM560AT-E

1E error

1d error

1F error

130

131

Error LCD flash

Simple Check Method for Main Parts

Part name Check procedure

Indoor unit

132

TA sensor TC, TCJ sensor Caracteristics-2 Caracteristics-1

133

Caracteristics-5

134

TH sensor

135

No. Part name Procedure Remarks

Detachment

Attachment

136

Part name Procedure Remarks

137

Fan motor 1. Detachment

138

139

No. Part name Procedure

Drain pan 1. Detachment

140

141

142

Replacement of Distributor Assembly

Cutting

RAV-SM800UT-E

143

144

Replacement of Main Parts Built-in type

145

Procedure

AID-P710BH, P800BH, P1120BH

146

Supplement How to remove the electric parts box

Electric parts box

Hook

147

Replacements of Main Parts Hi-Wall type

Attachment of front panel

148

149

Replacement Procedure

Replacement Procedure of Service Main P.C. Board

150

Components

Mounting

Reference Explanation about functions of switches/jumpers

151

152

Parts layout of service P.C. board

153

Outdoor Unit

154

Procedure Remarks

Part name

155

Requirement

156

157

158

159

160

161

Requirement

162

163

164

165

166

Product

167

168

224

Part Description

Location

169

402 404 401 405 403

170

222

Concealed Duct Type

171

403 402 406 405

RBC-U21PGW E

172

High-Wall Type

173

174

411 410 406 408 402 401 413 412 404 403

175

Inverter

176

702 TE Sensor TS Sensor To Sensor TD Sensor 701 705 703 704

DKV-MO25743BO

177

178

706

179

180

403 402 404 405 408 401 406 407