|

| |

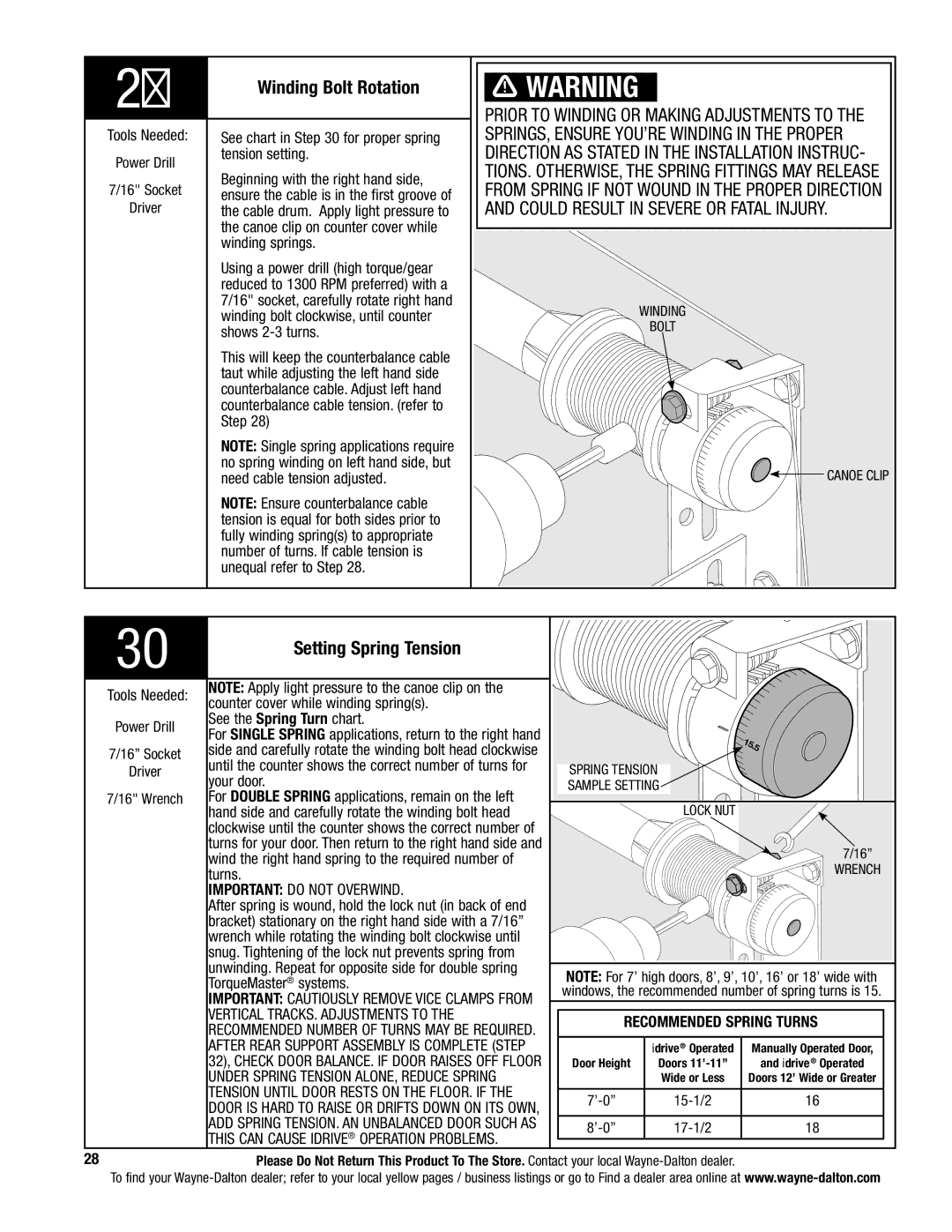

29 | Winding Bolt Rotation | |

| ||

|

| |

Tools Needed: | See chart in Step 30 for proper spring | |

Power Drill | tension setting. | |

Beginning with the right hand side, | ||

7/16" Socket | ||

ensure the cable is in the first groove of | ||

Driver | ||

the cable drum. Apply light pressure to | ||

| the canoe clip on counter cover while | |

| winding springs. | |

| Using a power drill (high torque/gear | |

| reduced to 1300 RPM preferred) with a | |

| 7/16" socket, carefully rotate right hand | |

| winding bolt clockwise, until counter | |

| shows | |

| This will keep the counterbalance cable | |

| taut while adjusting the left hand side | |

| counterbalance cable. Adjust left hand | |

| counterbalance cable tension. (refer to | |

| Step 28) | |

| NOTE: Single spring applications require | |

| no spring winding on left hand side, but | |

| need cable tension adjusted. | |

| NOTE: Ensure counterbalance cable | |

| tension is equal for both sides prior to | |

| fully winding spring(s) to appropriate | |

| number of turns. If cable tension is | |

| unequal refer to Step 28. | |

|

|

![]() WARNING

WARNING

Prior to winding or making adjustments to the springs, ensure you’re winding in the proper direction as stated in the Installation Instruc- tions. Otherwise, the spring fittings may release from spring if not wound in the proper direction and could result in severe or fatal injury.

Winding

Bolt

![]()

![]() Canoe Clip

Canoe Clip

30 | Setting Spring Tension |

|

|

|

|

|

|

| |

Tools Needed: | NOTE: Apply light pressure to the canoe clip on the |

|

|

|

counter cover while winding spring(s). |

|

|

| |

|

|

|

| |

Power Drill | See the Spring Turn chart. |

|

|

|

For SINGLE SPRING applications, return to the right hand |

|

|

| |

|

|

|

| |

7/16” Socket | side and carefully rotate the winding bolt head clockwise |

|

|

|

Driver | until the counter shows the correct number of turns for | Spring Tension |

| |

your door. |

| |||

| Sample Setting |

| ||

7/16" Wrench | For DOUBLE SPRING applications, remain on the left |

| Lock Nut |

|

| hand side and carefully rotate the winding bolt head |

|

| |

| clockwise until the counter shows the correct number of |

|

|

|

| turns for your door. Then return to the right hand side and |

|

| 7/16” |

| wind the right hand spring to the required number of |

|

| |

|

|

| Wrench | |

| turns. |

|

| |

|

|

|

| |

| IMPORTANT: Do Not Overwind. |

|

|

|

| After spring is wound, hold the lock nut (in back of end |

|

|

|

| bracket) stationary on the right hand side with a 7/16” |

|

|

|

| wrench while rotating the winding bolt clockwise until |

|

|

|

| snug. Tightening of the lock nut prevents spring from |

|

|

|

| unwinding. Repeat for opposite side for double spring | NOTE: For 7’ high doors, 8’, 9’, 10’, 16’ or 18’ wide with | ||

| TorqueMaster® systems. | |||

| IMPORTANT: Cautiously remove vice clamps from | windows, the recommended number of spring turns is 15. | ||

| vertical tracks. Adjustments to the | RECOMMENDED SPRING TURNS | ||

| recommended number of turns may be required. | |||

|

|

|

| |

| AFTER REAR SUPPORT ASSEMBLY IS COMPLETE (STEP |

| idrive® Operated | Manually Operated Door, |

| 32), CHECK DOOR BALANCE. If door raises off floor | Door Height | Doors | and idrive® Operated |

| under spring tension alone, Reduce spring |

| Wide or Less | Doors 12’ Wide or Greater |

| tension until door rests on the floor. If the | 16 | ||

| door is hard to raise or drifts down on its own, | |||

|

|

|

| |

| add spring tension. An unbalanced door such as | 18 | ||

| this can cause idrive® operation problems. |

|

|

|

28 | Please Do Not Return This Product To The Store. Contact your local |

| ||

To find your