| TorqueMaster® Spring | |

| Removal continued... | |

|

| |

Tools Needed: | If the counterbalance cable is still taut and | |

| the TorqueMaster® spring tube is difficult | |

Recommended | to rotate, that is an indication that spring | |

tension still exists on the left hand spring. | ||

tools from | ||

Repeat Steps 1 and 2 for releasing spring | ||

page 5 | ||

tension on the left hand side. | ||

| ||

| Step 4: Using a flat tip screwdriver, pry | |

| the counter gear and counter cover | |

| from the right hand end bracket (Fig. 4 | |

| on previous page). Discard the counter | |

| gear and counter cover. On double spring | |

| applications, repeat for left hand side. | |

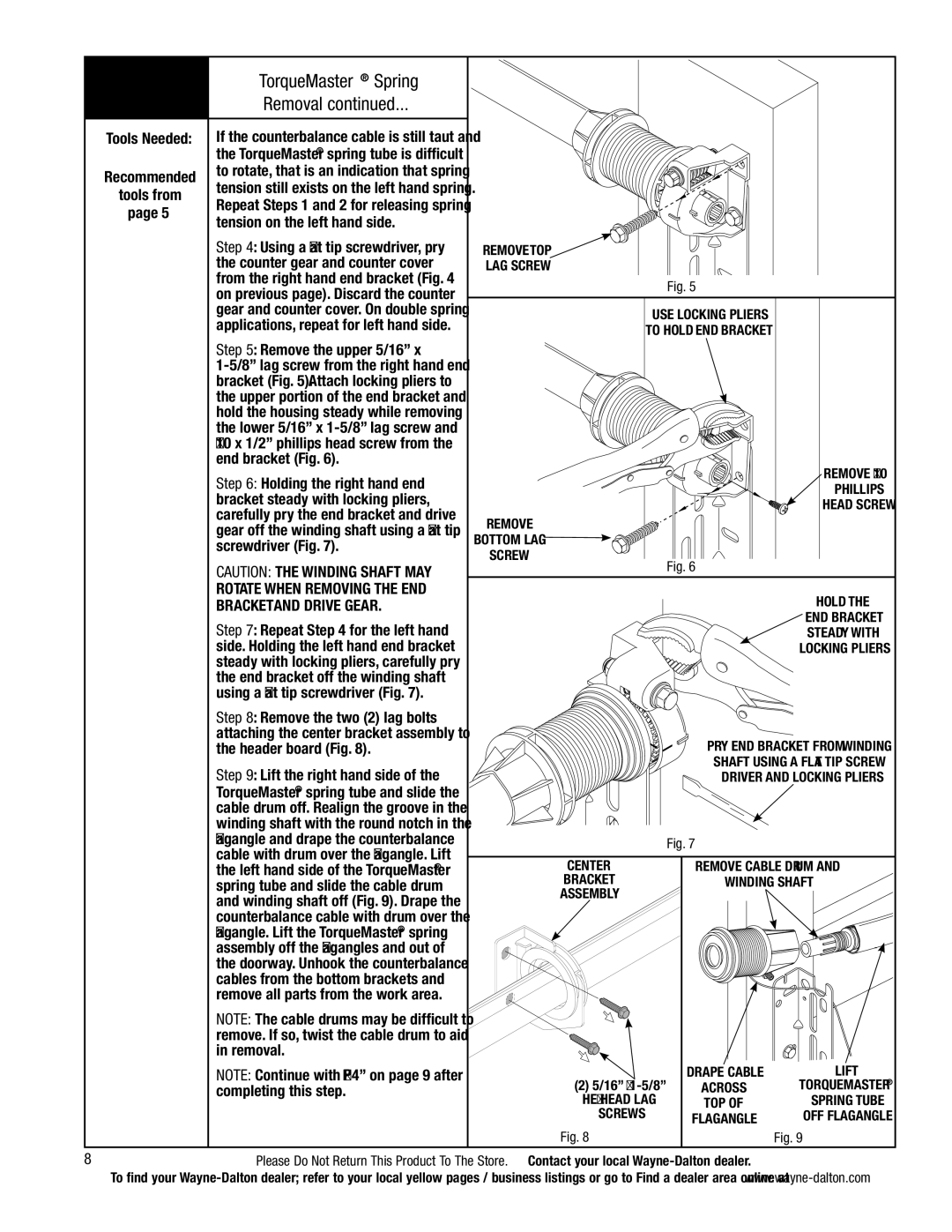

| Step 5: Remove the upper 5/16” x | |

| ||

| bracket (Fig. 5). Attach locking pliers to | |

| the upper portion of the end bracket and | |

| hold the housing steady while removing | |

| the lower 5/16” x | |

| #10 x 1/2” phillips head screw from the | |

| end bracket (Fig. 6). |

remove top![]() lag screw

lag screw

Fig. 5

use locking pliers

to hold end bracket

Step 6: Holding the right hand end |

bracket steady with locking pliers, |

carefully pry the end bracket and drive |

gear off the winding shaft using a flat tip |

screwdriver (Fig. 7). |

CAUTION: THE WINDING SHAFT MAY |

ROTATE WHEN REMOVING THE END |

BRACKET AND DRIVE GEAR. |

Step 7: Repeat Step 4 for the left hand |

side. Holding the left hand end bracket |

steady with locking pliers, carefully pry |

the end bracket off the winding shaft |

using a flat tip screwdriver (Fig. 7). |

Step 8: Remove the two (2) lag bolts |

attaching the center bracket assembly to |

remove

bottom lag![]()

screw

remove #10

phillips

head screw

Fig. 6

hold the

end bracket steady with locking pliers

the header board (Fig. 8). |

Step 9: Lift the right hand side of the |

TorqueMaster® spring tube and slide the |

cable drum off. Realign the groove in the |

winding shaft with the round notch in the |

flagangle and drape the counterbalance |

cable with drum over the flagangle. Lift |

the left hand side of the TorqueMaster® |

spring tube and slide the cable drum |

and winding shaft off (Fig. 9). Drape the |

counterbalance cable with drum over the |

flagangle. Lift the TorqueMaster® spring |

assembly off the flagangles and out of |

the doorway. Unhook the counterbalance |

cables from the bottom brackets and |

remove all parts from the work area. |

NOTE: The cable drums may be difficult to |

remove. If so, twist the cable drum to aid |

in removal. |

NOTE: Continue with “P4” on page 9 after |

completing this step. |

| pry end bracket from winding |

| shaft using a flat tip screw |

| driver and locking pliers |

| Fig. 7 |

CENTER | remove cable drum and |

BRACKET | winding shaft |

ASSEMBLY |

|

| drape cable | lift |

(2) 5/16” x | across | TorqueMaster® |

hex head lag | top of | Spring Tube |

screws | flagangle | off flagangle |

Fig. 8 |

| Fig. 9 |

|

8Please Do Not Return This Product To The Store. Contact your local

To find your