Specifications and Dimensions

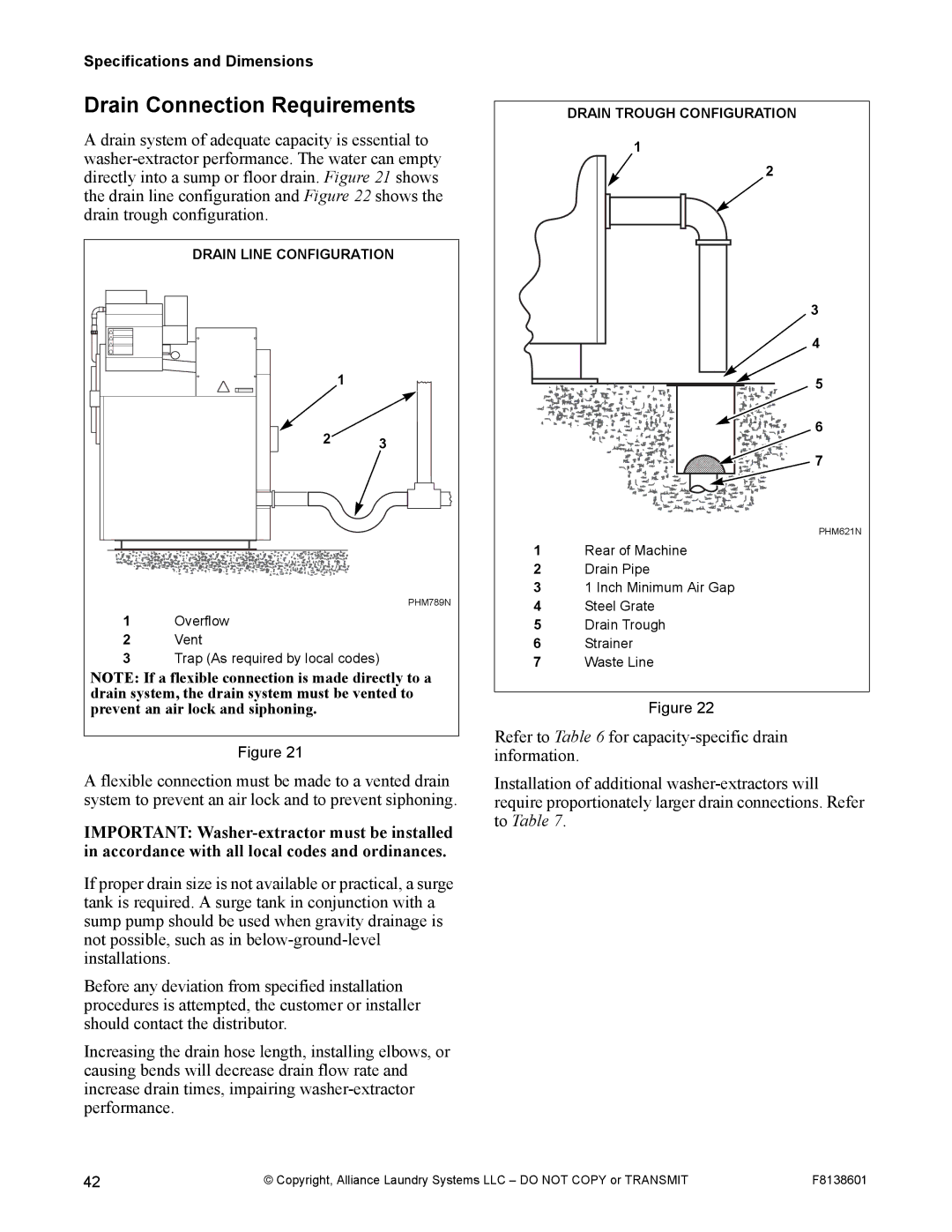

IMPORTANT: Do not block the overflow vent above the drain line.

If water or suds flow from the overflow vent and the machine has been verified to be operating properly with proper water levels and correct amount of laundry chemicals, a drain line may be added to the vent and routed to a drain trough.

1.Remove the riveted bracket on the rear panel for access to the overflow vent pipe.

2.Route a drain pipe from the vent pipe to a drain trough. Drain pipe should be routed straight across or down and be suspended above drain trough by at least 3 inches (7.62 cm).

IMPORTANT: Do not route the overflow vent pipe to a direct drain system.

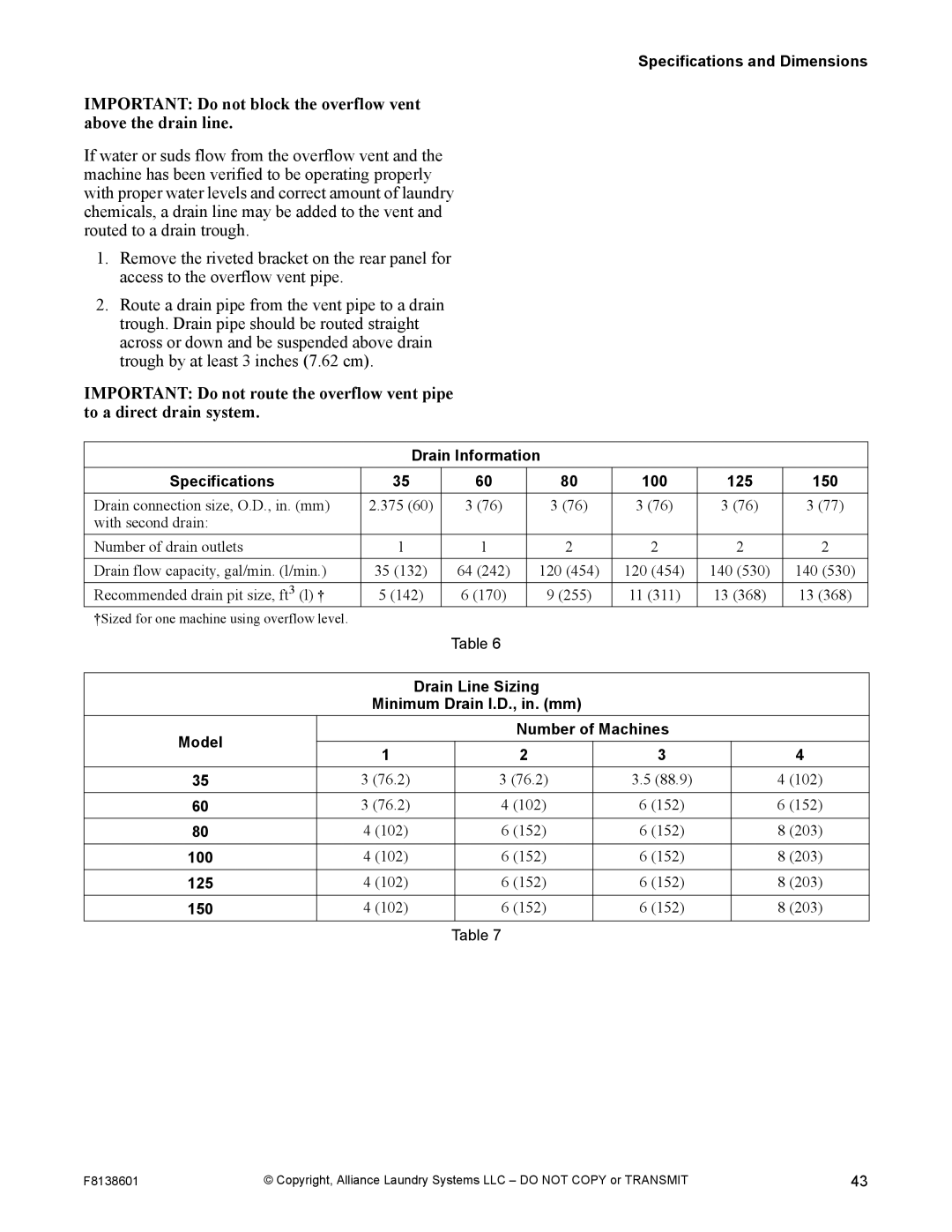

Drain Information

Specifications | 35 |

| 60 | 80 | 100 | 125 | 150 | |||

Drain connection size, O.D., in. (mm) | 2.375 (60) | 3 | (76) | 3 (76) | 3 | (76) | 3 | (76) | 3 | (77) |

with second drain: |

|

|

|

|

|

|

|

|

|

|

Number of drain outlets | 1 |

| 1 | 2 |

| 2 |

| 2 |

| 2 |

Drain flow capacity, gal/min. (l/min.) | 35 (132) | 64 | (242) | 120 (454) | 120 (454) | 140 (530) | 140 (530) | |||

Recommended drain pit size, ft3 (l) † | 5 (142) | 6 (170) | 9 (255) | 11 | (311) | 13 | (368) | 13 | (368) | |

†Sized for one machine using overflow level. |

|

|

|

|

|

|

|

|

|

|

Table 6

Drain Line Sizing

Minimum Drain I.D., in. (mm)

Model |

| Number of Machines |

| ||

1 | 2 | 3 | 4 | ||

| |||||

35 | 3 (76.2) | 3 (76.2) | 3.5 (88.9) | 4 (102) | |

60 | 3 (76.2) | 4 (102) | 6 (152) | 6 (152) | |

80 | 4 (102) | 6 (152) | 6 (152) | 8 (203) | |

100 | 4 (102) | 6 (152) | 6 (152) | 8 (203) | |

125 | 4 (102) | 6 (152) | 6 (152) | 8 (203) | |

150 | 4 (102) | 6 (152) | 6 (152) | 8 (203) | |

Table 7

F8138601 | © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT | 43 |