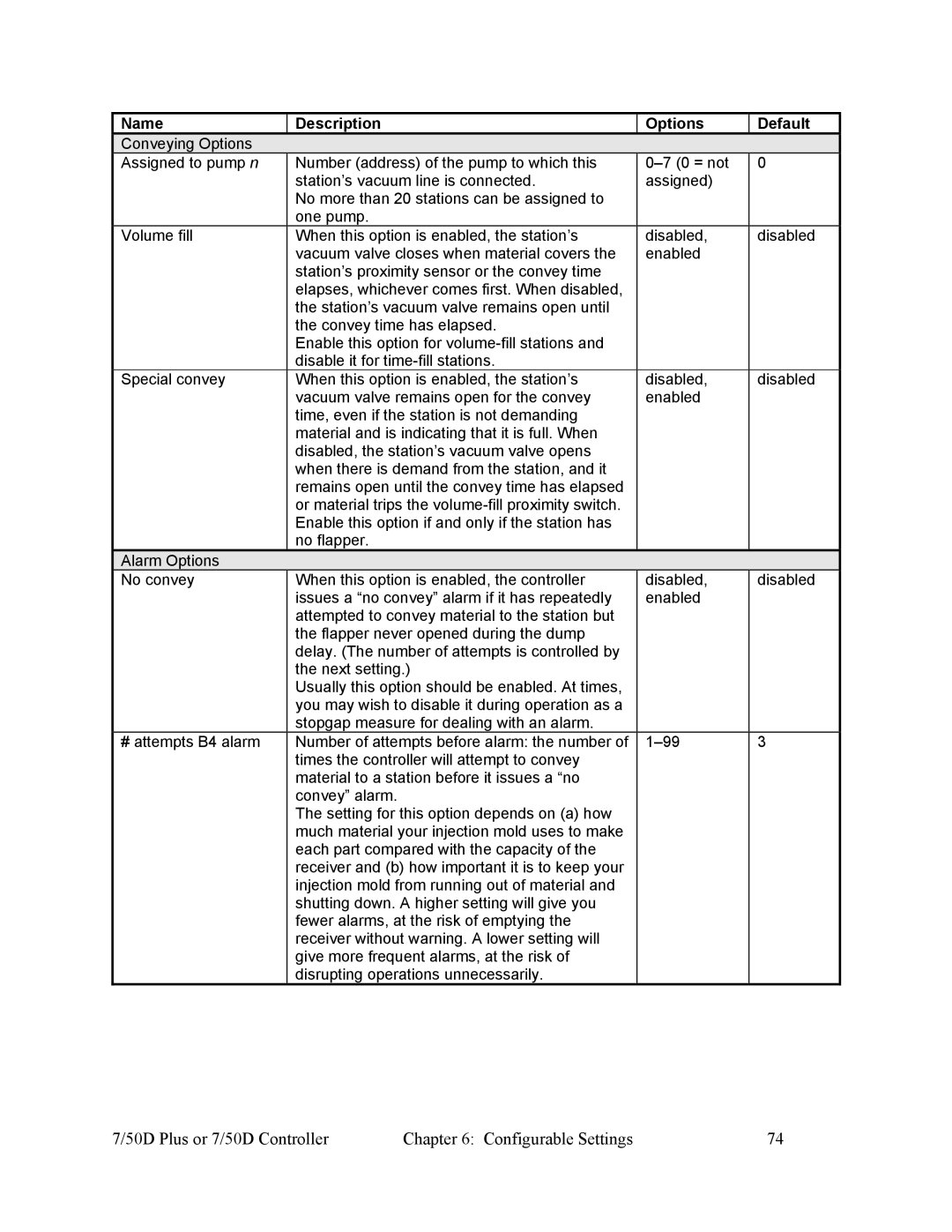

Name | Description | Options | Default |

Conveying Options |

|

|

|

Assigned to pump n | Number (address) of the pump to which this | 0 | |

| station’s vacuum line is connected. | assigned) |

|

| No more than 20 stations can be assigned to |

|

|

| one pump. |

|

|

Volume fill | When this option is enabled, the station’s | disabled, | disabled |

| vacuum valve closes when material covers the | enabled |

|

| station’s proximity sensor or the convey time |

|

|

| elapses, whichever comes first. When disabled, |

|

|

| the station’s vacuum valve remains open until |

|

|

| the convey time has elapsed. |

|

|

| Enable this option for |

|

|

| disable it for |

|

|

Special convey | When this option is enabled, the station’s | disabled, | disabled |

| vacuum valve remains open for the convey | enabled |

|

| time, even if the station is not demanding |

|

|

| material and is indicating that it is full. When |

|

|

| disabled, the station’s vacuum valve opens |

|

|

| when there is demand from the station, and it |

|

|

| remains open until the convey time has elapsed |

|

|

| or material trips the |

|

|

| Enable this option if and only if the station has |

|

|

| no flapper. |

|

|

Alarm Options |

|

|

|

No convey | When this option is enabled, the controller | disabled, | disabled |

| issues a “no convey” alarm if it has repeatedly | enabled |

|

| attempted to convey material to the station but |

|

|

| the flapper never opened during the dump |

|

|

| delay. (The number of attempts is controlled by |

|

|

| the next setting.) |

|

|

| Usually this option should be enabled. At times, |

|

|

| you may wish to disable it during operation as a |

|

|

| stopgap measure for dealing with an alarm. |

|

|

# attempts B4 alarm | Number of attempts before alarm: the number of | 3 | |

| times the controller will attempt to convey |

|

|

| material to a station before it issues a “no |

|

|

| convey” alarm. |

|

|

| The setting for this option depends on (a) how |

|

|

| much material your injection mold uses to make |

|

|

| each part compared with the capacity of the |

|

|

| receiver and (b) how important it is to keep your |

|

|

| injection mold from running out of material and |

|

|

| shutting down. A higher setting will give you |

|

|

| fewer alarms, at the risk of emptying the |

|

|

| receiver without warning. A lower setting will |

|

|

| give more frequent alarms, at the risk of |

|

|

| disrupting operations unnecessarily. |

|

|

7/50D Plus or 7/50D Controller | Chapter 6: Configurable Settings | 74 |