6

Calibration

Introduction

This chapter describes the calibration procedures for the Electronic Load and gives a sample calibration program. The Electronic Load should be calibrated annually, or whenever certain repairs are made (refer to the Service Manual). Calibration is accomplished entirely in software by sending calibration constants to the Electronic Load via the GPIB. This means that the Electronic Load can be calibrated without removing its cover, or removing it from its cabinet if rack mounted.

There are three DACs in the Electronic Load that must be calibrated - a main DAC, a readback DAC, and a transient level DAC. Six ranges must be calibrated for both the main DAC and the transient DAC - a voltage range, a low resistance range, a middle resistance range, a high resistance range, a low current range, and a high current range. The main DAC requires two operating points to be calibrated for each range - a high point and a low point. The transient DAC requires only the high operating point to be calibrated for each range; it uses the same low operating point as the main DAC. Note that the transient level for the middle and high resistance ranges is lower than the high level of the main DAC.

The readback DAC is only calibrated for the high current range and the voltage range. It also requires two operating points to be calibrated for each range - a high point and a low point. For the sake of convenience you can use the same values to calibrate the main and the readback DAC, but you could also use different values to optimize accuracy.

Note | All calibration must be done when the Electronic Load is at room temperature. |

Example Programs

The example programs in this chapter are written using the, Agilent BASIC Language. If you are using an HP Series 200/300 computer, simply type in the programs and run them. At appropriate places in the program you will be prompted to measure and enter values into the computer and verify that the values are within specifications.

If you are using a different computer or programming language, you will have to modify the programs before you can run them.

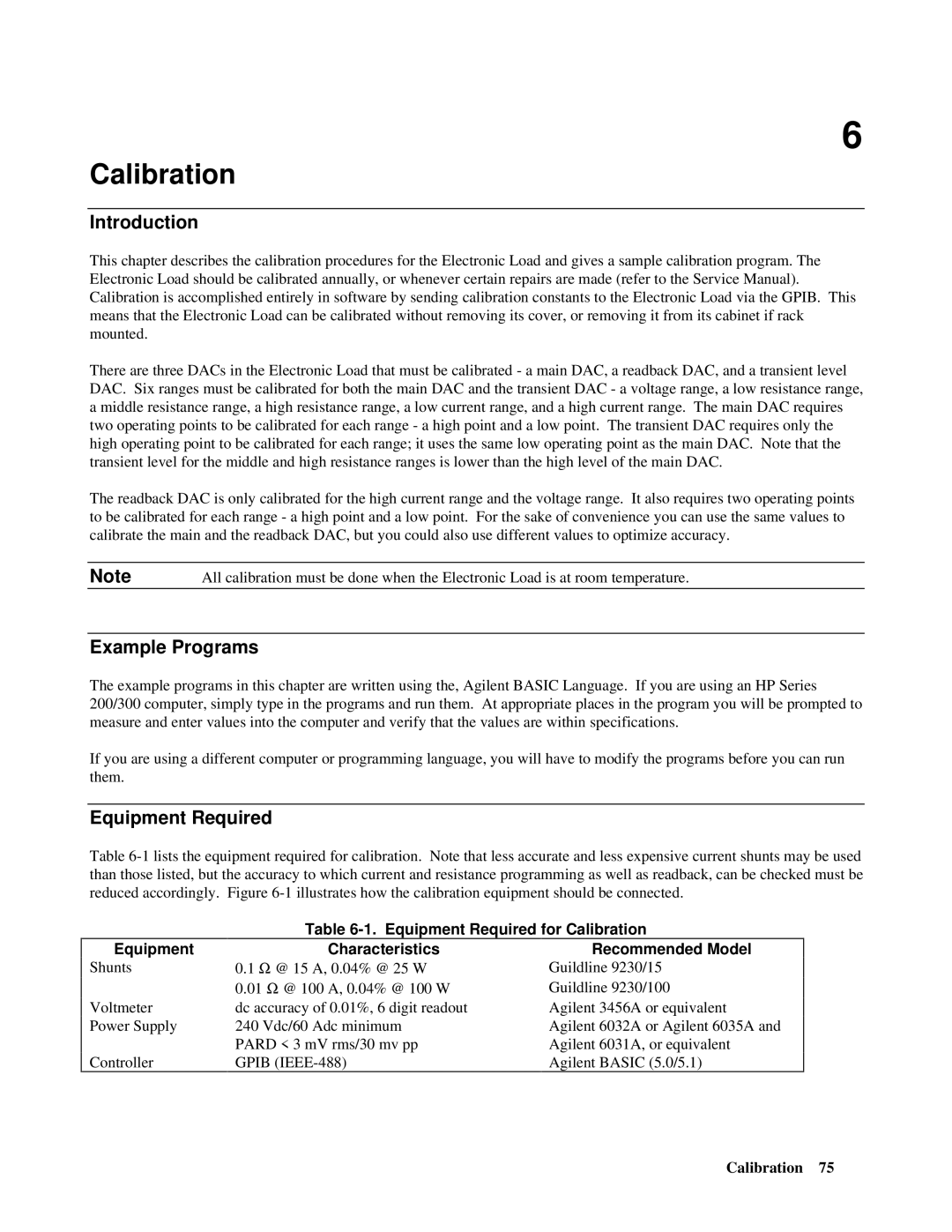

Equipment Required

Table

| Table | |

Equipment | Characteristics | Recommended Model |

Shunts | 0.1 Ω @ 15 A, 0.04% @ 25 W | Guildline 9230/15 |

| 0.01 Ω @ 100 A, 0.04% @ 100 W | Guildline 9230/100 |

Voltmeter | dc accuracy of 0.01%, 6 digit readout | Agilent 3456A or equivalent |

Power Supply | 240 Vdc/60 Adc minimum | Agilent 6032A or Agilent 6035A and |

| PARD < 3 mV rms/30 mv pp | Agilent 6031A, or equivalent |

Controller | GPIB | Agilent BASIC (5.0/5.1) |