Agilent

Windows Adobe Acrobat Reader

Agilent Technologies, Inc

Introducing the N8201A Performance Downconverter

Page

Contents

If the Instrument’s Hostname and PC Cannot Communicate

Power

If the LAN LED is Red

If the Software Driver Will Not Open the Connection

100

If LOG Video Option V7L

LAN LXI Trigger Bus

101

107

Service and Support

106

111

Software Installation

Installing Software and Instrument Drivers

Click Instrument Drivers

Install Microsoft .NET Version

Select Microsoft Version

Install the Agilent I/O Libraries

Select Agilent I/O Libraries

Install the IVI Shared Components

Select IVI Shared Components

Software Installation

Install the Agilent Synthetic Instrument Finder

Select Agilent Synthetic Instrument Finder

Install the Agilent Synthetic Instrument GUI

Select Agilent Synthetic Instrument GUI

Install the IVI-COM Drivers

Click Finish

Software Installation

If Option H02 is Installed

Installing Optional Software and Instrument Drivers

To Verify that Option H02 is Installed

If Option H02 is Not Installed

Installing Optional Software and Instrument Drivers on

Select Agilent N8201A Option H02 Spectrum Analyzer GUI

Software Installation

Optional . Install the Microsoft Virtual Machine VM

Select Microsoft Virtual Machine VM

Software Installation

Optional . Install the Apache Http Server

Select Apache Http Server

Software Installation

Click Finish

Optional . Install the SA Remote Web Server

Select SA Remote Web Server

Restart the computer

Software Installation

Hardware Setup and Configuration

Troubleshooting on

Optional Prepare the Instrument for Rack Mounting

Unpack the N8201A Performance Downconverter

Verify the Shipment

Literature included with the shipment

Connect LAN Cables and Turn On Power

Optional Connect to a LAN with a Cross-Over LAN Cable on

Hardware Setup and Configuration

Optional Connect to a LAN with a Cross-Over LAN Cable

Verify Connection with Synthetic Instrument Finder

From the Windows Desktop

With Option H02 installed, refer to

With Option H02 not installed, refer to

Using the Agilent Synthetic Instrument GUI on

Optional . Connect to an SA Remote Web Server on

Software cannot be used

Instrument Drivers on

Hardware Setup and Configuration

Click Add Interface

To Installing Optional Software and Instrument Drivers on

Optional . Connect to an SA Remote Web Server

Select Remote Gpib via E5810 or Remote IO Server

IP Address

Hardware Setup and Configuration

From the Windows Desktop

Hardware Setup and Configuration

Hardware Setup and Configuration

Select Web Control SA on the left of the web

Instrument Connections

Optional . Verify Operation 3 GHz

Performing a Self-Test

Agilent Synthetic Instrument GUI on

Perform the following procedure to run a self-test

Close SA Remote Web Server

Following dialog box should appear

Measurement Procedure

Downconverter 7.5 MHz Out Spectrum Analyzer RF Input

Downconverter to Spectrum Analyzer Connections

Downconverter to Source Connections

Hardware Setup and Configuration

Measurement Procedure

Troubleshooting

Alternative Ways to Verify Connectivity to the PC

How to Use the Synthetic Instrument Finder

Right-Pane Functions

Left-Pane Functions

Clipboard for use in other applications

How to Reset the LAN Configuration

LAN RST

Connector on your internal local area network or LAN hub

How to Set a Static IP Address

Configurations

N8201A Performance Downconverter on

Hardware Setup and Configuration

Hardware Setup and Configuration

Then cycle the power of the PC

From a DOS Window

How to Troubleshoot Connectivity Problems on the Network

How to Determine a PCs Configuration Settings

From the PCs Control Panel

Hardware Setup and Configuration

Possible Causes

If the Instrument’s Hostname and PC Cannot Communicate

See If the Instrument was Unable to Join the LAN on

If the Instrument Web Page is Not Visible

If the Software Driver Will Not Open the Connection

Using Agilent Synthetic Instrument GUI

Downconverter can be controlled with any of the following

Which interface should be used

Starting the Agilent Synthetic Instrument GUI

Left Pane

Right Pane

Connect

Features of the Agilent Synthetic Instrument GUI

File Menu

Reconnect

Help

Load Settings

Save Settings

Disconnect

Error Log

Start

Dynamic Help

Dynamic Help

Instrument Information

Event Log

Frequency List

Settings on the Agilent Synthetic Instrument GUI

Frequency

Sends the new trigger settings to the instrument

Trigger Source set to ALARM0

Controls available when Trigger Source is set to ALARM0

Trigger Detection

If Output

Level

Input RF

Reference Oscillator

Preselector Option

Adjust

PreSelector Enabled

External Mixer

Events Settling Events and Event Logging

Selects the channel to configure. Possible values are

Calibration

Settling Event

Event Logging

Refresh All Values

Preset

Re-reads the settings from the instrument

Front and Rear Panel Features

Option V7L

N8201A Performance Downconverter Front Panel Features

Power

LAN LED indicator works in the following states

Line Power LED

Power indicator has the following states

1588 LED

Ieee 1588 LED clock status has the following states

EXT Mixer

Noise Source +28 V Pulsed Option

Connector SMB male Impedance of 50 ohm nominal

If LOG Video Option V7L

MHz

N8201A Performance Downconverter Rear Panel Features

AC Power Receptacle

LXI Trigger Bus

This is not a functional connector

This connector is for factory testing only

Documentation CD

Interconnect Cabling

IG G E R S

Operational Considerations

Agilent 89601A Vector Signal Analysis Software

Configuring the Local Area Network LAN Interface

Preventive Maintenance

To extend the life of your cables or connectors

Using, Inspecting, and Cleaning RF Connectors

RF Cable and Connector Care

Repeatability

SMA Connector Precautions

Proper Connector Torque

Connector Wear and Damage

Before connecting the cables to any device

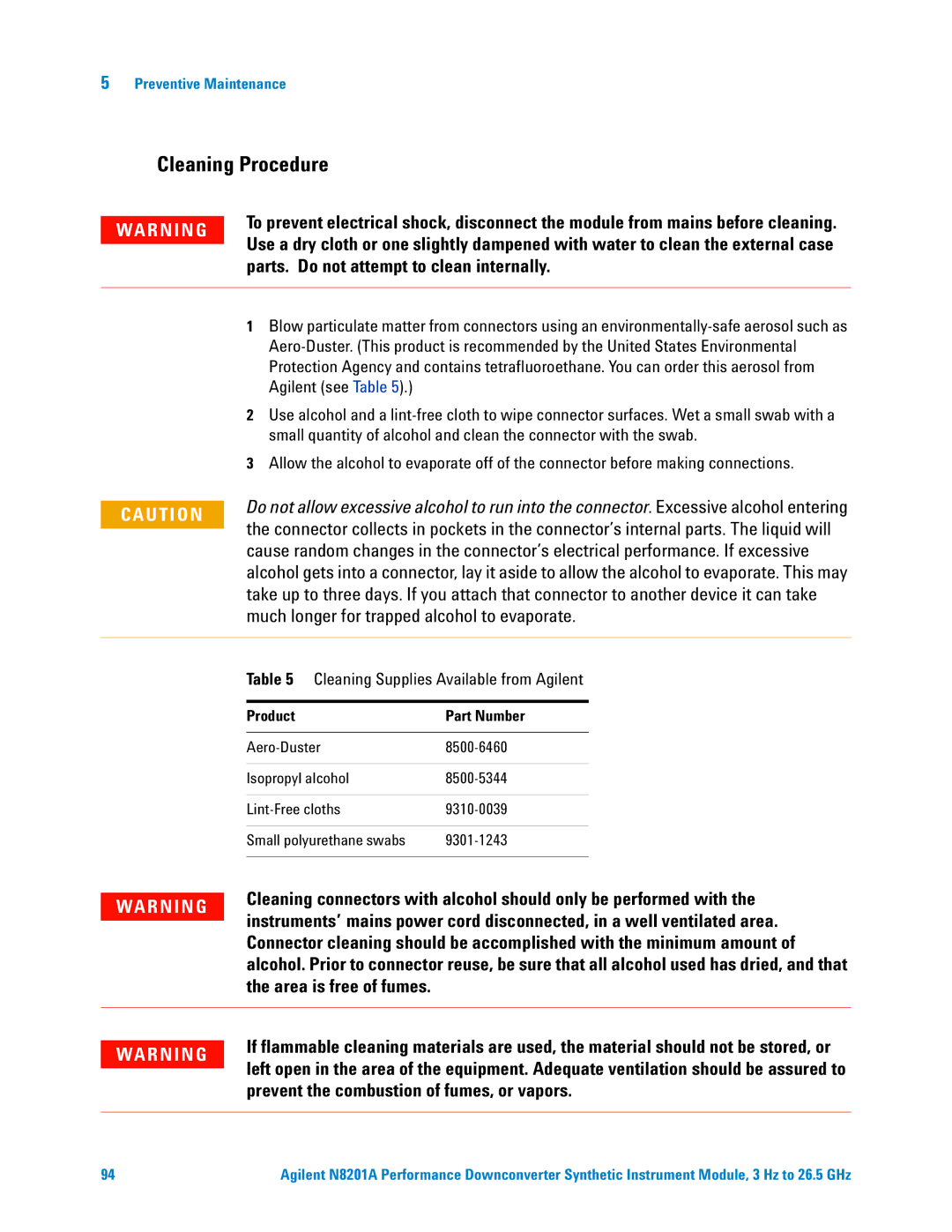

Cleaning Supplies Available from Agilent

Cleaning Procedure

Parts. Do not attempt to clean internally

Area is free of fumes

General Procedures and Techniques

GPIB, 3.5 mm, Type-N, power sensor, and BNC connectors

Precision 3.5 mm connectors

Connector Removal

Gpib connectors

Mm connectors with a gold hex nut

Bent Semirigid Cables

Required tools

Instrument Removal

Standard instrument

To remove a half-width instrument from a system rack

Half-Rack-Width Instrument

Bench Top Instrument

To remove an instrument from a bench top system

Standard rack instrument

Instrument Installation

To install an instrument

To install the instrument in a rack

To install an instrument in a bench top system

102

Service, Support, and Safety Information

Safety and Regulatory Information on Service and Support on

Safety Summary

Safety and Regulatory Information

Safety

General Compliance with German Noise Requirements

17.3.4

Equipment Installation

Acoustic Noise Emission/Geraeuschemission

Flames

Environmental Conditions

Before Applying Power

Service personnel

Personnel

Fields

Magnetic Susceptibility

Ground the Instrument or System

Hz to 500 Hz frequency range

Fuses and Circuit Breakers

Maintenance

Safety symbols and Instrument Markings

109

Safety symbols Definition Frame or chassis terminal

Any servicing unless you are qualified to do so

Service and Support

Agilent on the Web

By Agilent Technologies

Return Procedure

Shipping the Instrument

Glossary

Glossary

Would become

116

Numerics

Index-2