Service

Top Load Washer

Table of Contents

Important Information

Important Notices for Consumers and Servicers

Recognize Safety Symbols, Words, and Labels

Important Safety Information

General Information

Model Identification

Proper Grounding and Polarization of 120 Volts Wall Outlets

Grounding Instructions

General Operation Definition

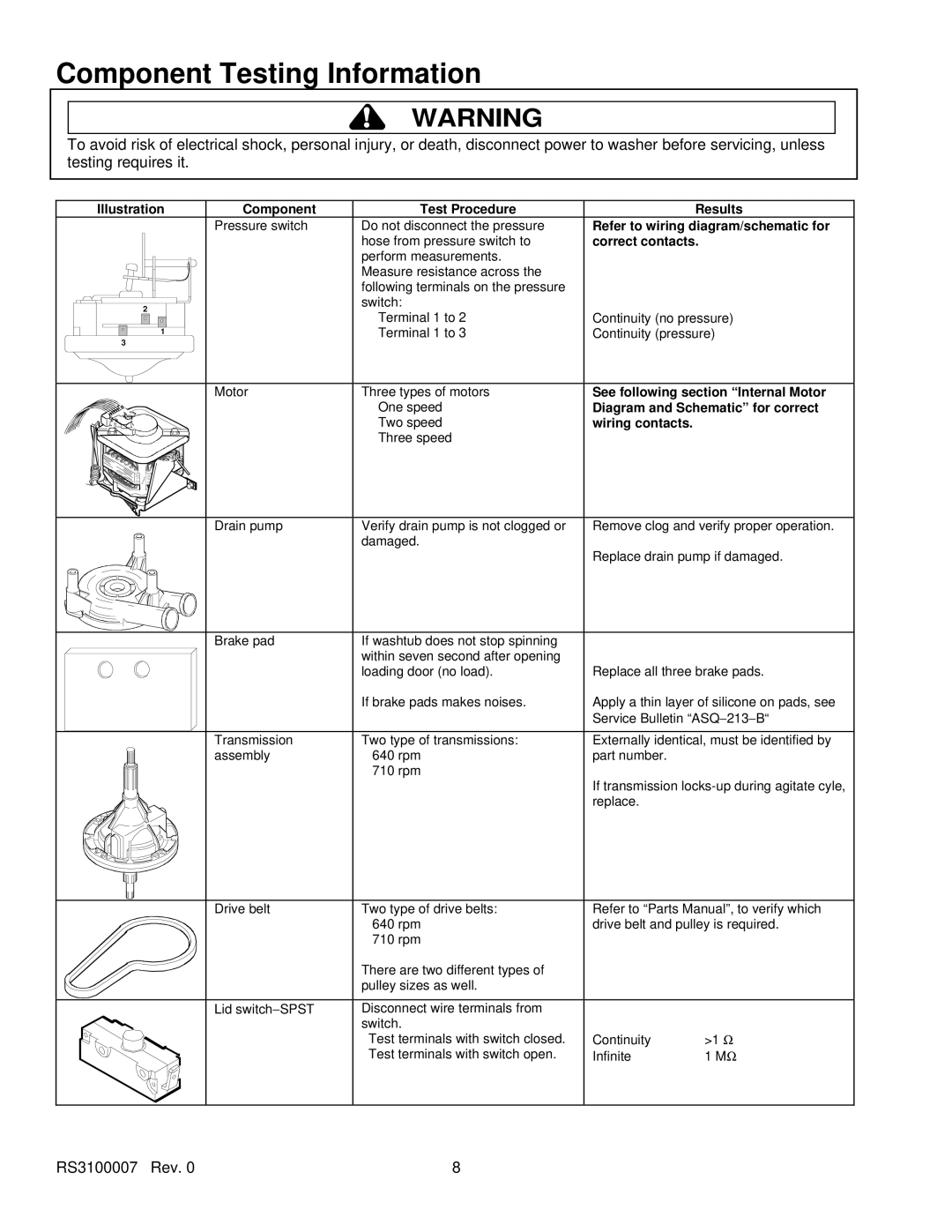

Component Testing Information

Component Test Procedure Results

Diagram and Schematic for correct

Internal Motor Diagram and Schematic

Wire harness Connection Block White Brown Yellow Red Blue

Blue

White Red Brown

Violet

Motor Assembly Three speed motor

Black White YellowBlue White/Black

Troubleshooting Procedures

No hot water Possible Cause Result

No cold water Possible Cause Result

No warm water Possible Cause Result

Timer does not advance Possible Cause Result

Motor does not operate Possible Cause Result

No agitation Possible Cause Result

Constant agitation Possible Cause Result

Possible Cause Result

Slow spin or no spin Possible Cause Result

Constant spin Possible Cause Result

Washer locks-up or binding Possible Cause Result

Outer tub does not empty Possible Cause Result

Excessive vibration Possible Cause Result

Water leaking from outer tub Possible Cause Result

Disassembly Procedures

Control Hood Assembly

Timer

Control Hood End Panels

Temperature and Speed Switch

Pressure Switch

Rocker Switch

Graphic Panel

Loading Door

Agitator, Drive Bell and Seal Assembly

Agitator

Installing Drive Bell

Motor and Mounting Bracket

Service Access Panel

Front Panel

Reassembly of Pump and Belt

Pump Mounting screws Rear Pump leg Assembly

Embosses Motor Assembly

Pump and Belt Removal

Motor Disassembly

Motor Switch

Motor Drive Pulley

Idler Lever and Pulley

Cabinet Top

Door Switch

Mixing Valve

Outer Tub

Tub Cover and Gasket

Washtub and Balance Ring

Drive Pulley, Helix and Brake

Weldment and Bearing Assembly

Friction Ring

Transmission Assembly

Upper Bearing Assembly

Appendix a

Installation Instructions

Standpipe

Tub Wall Unit

Positionwasher and Level

Prong grounded outlet only

Installation Summary

Adjustable leg Extension Kit

Observe all local codes and ordinances

Siphon Break Kit

Longer Water Inlet Hoses

Installation Requirements

Appendix B

Top Loading Washer

Recognize Safety Symbols, Words, Labels

Thank you for buying an Amana washer

Important Safety Information

Starting the Wash

Starting the Wash contd

Close washer lid

Cycles

What do the little numbers mean?

Clean softener dispenser after each use. Remove dispenser

Dispensers

Features, Hints, and Care

Follow the Colors

Moving and Storage

Cold Storage and Non-Use Periods

Trouble Shooting

Topic Possible Cause Solution

Trouble Shooting contd

Water

Amana Washer Warranty

Repairs resulting from the following

Appendix C

Contents

Top Loading Washer

Important Safety Information

Recognize Safety Symbols, Words, Labels

Asure Extended Service Plan

Parts and Accessories

Important Information Thank you for buying an Amana washer

Save Time and Money

Water Supply Requirements

Before You Install

Electrical Requirements

Washer Dimensions

Low Standpipe Installation

Location

Risers

HOT Cold

Questions?

Wall Unit

Operating Instructions Washer Control Panel

To Wash Clothes

Ex-Large Full

Warm/Cold

Operating Instructions

Helpful Hints and Features

Resetting Timer

Pauses

Bleach Dispenser

Care and Cleaning

Safety Spin

Automatic Balance System

General Washer Care

Before Calling Service

Topic Possible Cause Solution

Topic Possible Cause Solution

Cold Storage and Non-Use Periods

Cold Weather Care

Cold Weather Storage

Vacations and Extended Non-Use

Owner’s Responsibilities

Warranty

Warranty Provides For

Fast Track for Installing Washer

See manual for details