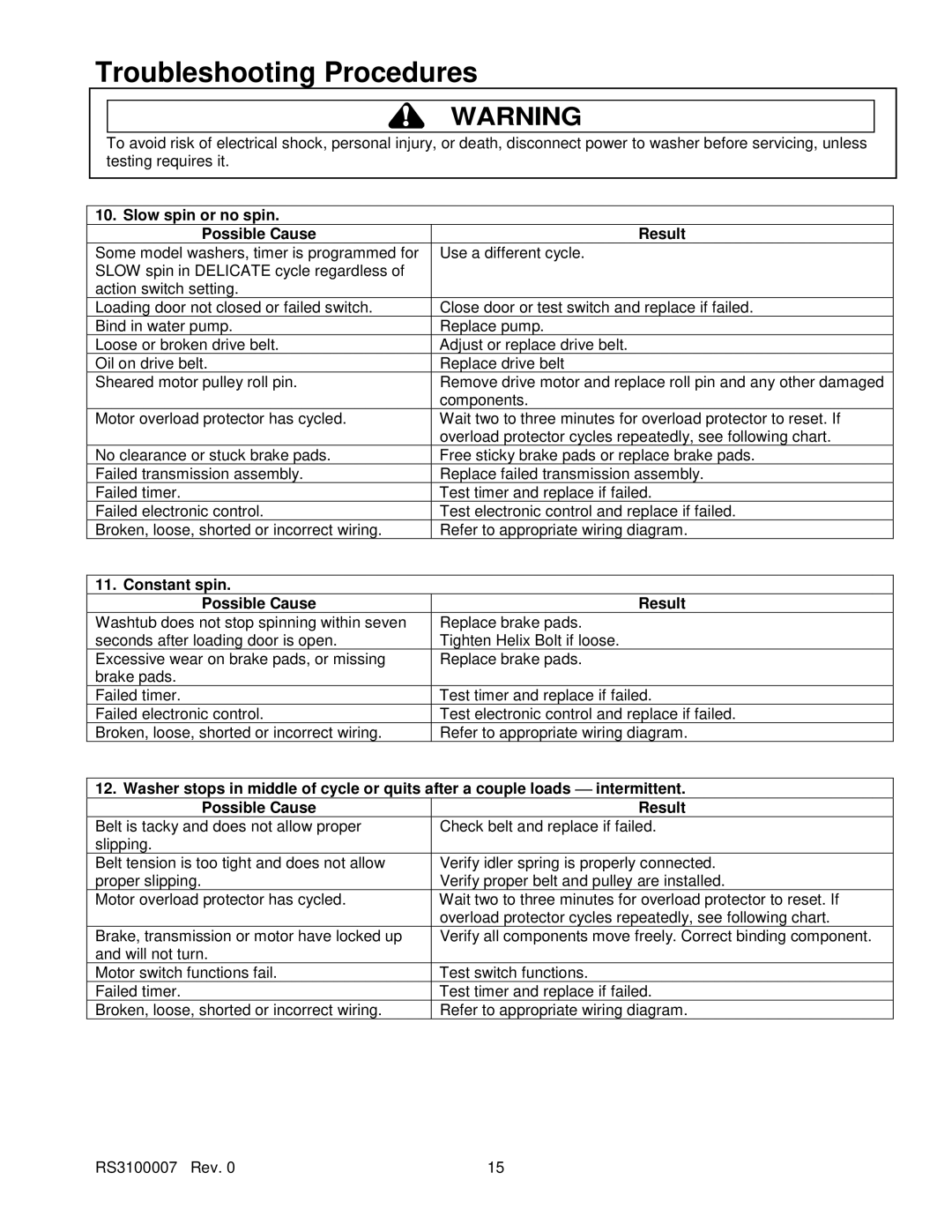

Troubleshooting Procedures

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless testing requires it.

10. Slow spin or no spin.

Possible Cause | Result |

Some model washers, timer is programmed for | Use a different cycle. |

SLOW spin in DELICATE cycle regardless of |

|

action switch setting. |

|

Loading door not closed or failed switch. | Close door or test switch and replace if failed. |

Bind in water pump. | Replace pump. |

Loose or broken drive belt. | Adjust or replace drive belt. |

Oil on drive belt. | Replace drive belt |

Sheared motor pulley roll pin. | Remove drive motor and replace roll pin and any other damaged |

| components. |

Motor overload protector has cycled. | Wait two to three minutes for overload protector to reset. If |

| overload protector cycles repeatedly, see following chart. |

No clearance or stuck brake pads. | Free sticky brake pads or replace brake pads. |

Failed transmission assembly. | Replace failed transmission assembly. |

Failed timer. | Test timer and replace if failed. |

Failed electronic control. | Test electronic control and replace if failed. |

Broken, loose, shorted or incorrect wiring. | Refer to appropriate wiring diagram. |

|

|

11. Constant spin. |

|

Possible Cause | Result |

Washtub does not stop spinning within seven | Replace brake pads. |

seconds after loading door is open. | Tighten Helix Bolt if loose. |

Excessive wear on brake pads, or missing | Replace brake pads. |

brake pads. |

|

Failed timer. | Test timer and replace if failed. |

Failed electronic control. | Test electronic control and replace if failed. |

Broken, loose, shorted or incorrect wiring. | Refer to appropriate wiring diagram. |

| |

12. Washer stops in middle of cycle or quits after a couple loads ⎯ intermittent. | |

Possible Cause | Result |

Belt is tacky and does not allow proper | Check belt and replace if failed. |

slipping. |

|

Belt tension is too tight and does not allow | Verify idler spring is properly connected. |

proper slipping. | Verify proper belt and pulley are installed. |

Motor overload protector has cycled. | Wait two to three minutes for overload protector to reset. If |

| overload protector cycles repeatedly, see following chart. |

Brake, transmission or motor have locked up | Verify all components move freely. Correct binding component. |

and will not turn. |

|

Motor switch functions fail. | Test switch functions. |

Failed timer. | Test timer and replace if failed. |

Broken, loose, shorted or incorrect wiring. | Refer to appropriate wiring diagram. |

RS3100007 Rev. 0 | 15 |