General Information

General Operation Definition

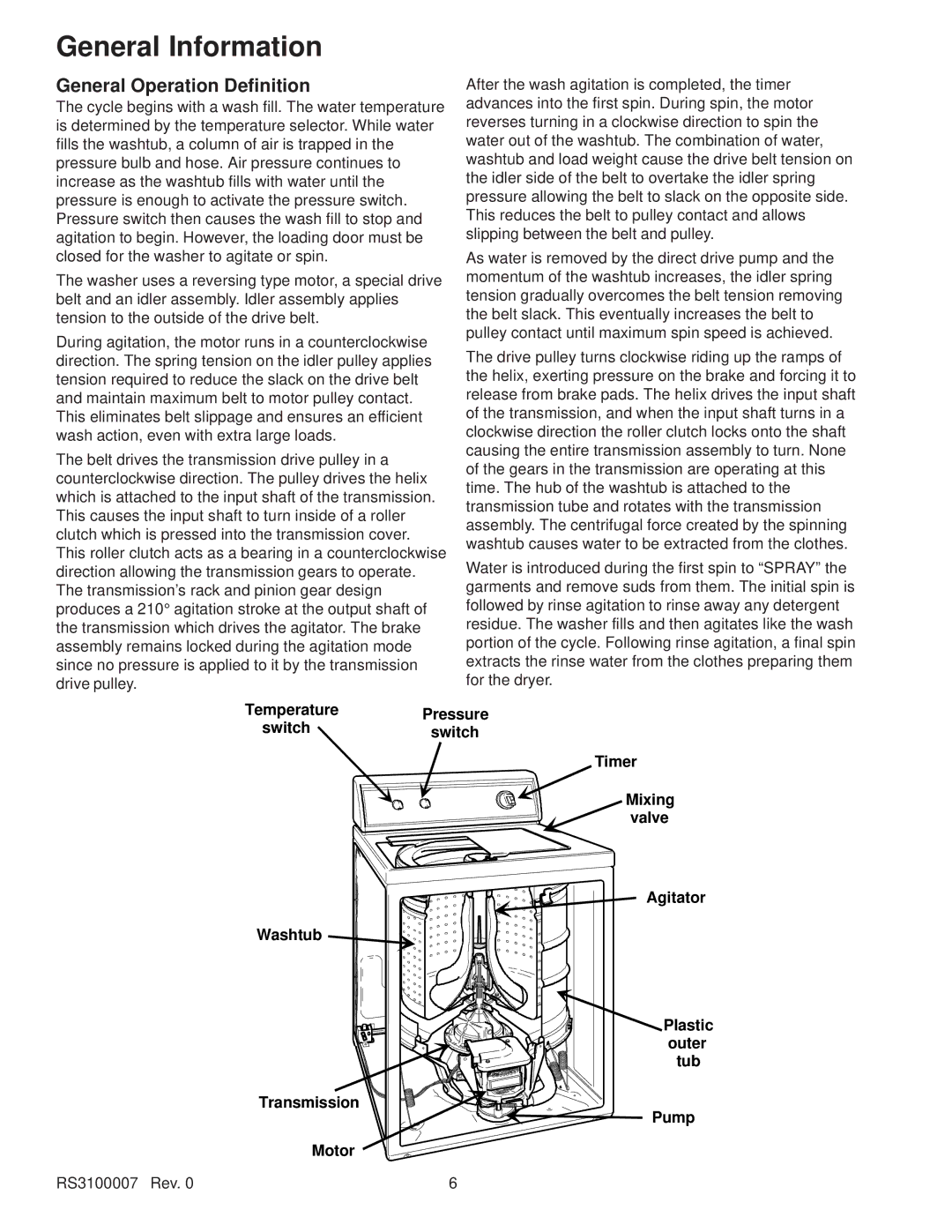

The cycle begins with a wash fill. The water temperature is determined by the temperature selector. While water fills the washtub, a column of air is trapped in the pressure bulb and hose. Air pressure continues to increase as the washtub fills with water until the pressure is enough to activate the pressure switch. Pressure switch then causes the wash fill to stop and agitation to begin. However, the loading door must be closed for the washer to agitate or spin.

The washer uses a reversing type motor, a special drive belt and an idler assembly. Idler assembly applies tension to the outside of the drive belt.

During agitation, the motor runs in a counterclockwise direction. The spring tension on the idler pulley applies tension required to reduce the slack on the drive belt and maintain maximum belt to motor pulley contact. This eliminates belt slippage and ensures an efficient wash action, even with extra large loads.

The belt drives the transmission drive pulley in a counterclockwise direction. The pulley drives the helix which is attached to the input shaft of the transmission. This causes the input shaft to turn inside of a roller clutch which is pressed into the transmission cover. This roller clutch acts as a bearing in a counterclockwise direction allowing the transmission gears to operate. The transmission’s rack and pinion gear design produces a 210° agitation stroke at the output shaft of the transmission which drives the agitator. The brake assembly remains locked during the agitation mode since no pressure is applied to it by the transmission drive pulley.

After the wash agitation is completed, the timer advances into the first spin. During spin, the motor reverses turning in a clockwise direction to spin the water out of the washtub. The combination of water, washtub and load weight cause the drive belt tension on the idler side of the belt to overtake the idler spring pressure allowing the belt to slack on the opposite side. This reduces the belt to pulley contact and allows slipping between the belt and pulley.

As water is removed by the direct drive pump and the momentum of the washtub increases, the idler spring tension gradually overcomes the belt tension removing the belt slack. This eventually increases the belt to pulley contact until maximum spin speed is achieved.

The drive pulley turns clockwise riding up the ramps of the helix, exerting pressure on the brake and forcing it to release from brake pads. The helix drives the input shaft of the transmission, and when the input shaft turns in a clockwise direction the roller clutch locks onto the shaft causing the entire transmission assembly to turn. None of the gears in the transmission are operating at this time. The hub of the washtub is attached to the transmission tube and rotates with the transmission assembly. The centrifugal force created by the spinning washtub causes water to be extracted from the clothes.

Water is introduced during the first spin to “SPRAY” the garments and remove suds from them. The initial spin is followed by rinse agitation to rinse away any detergent residue. The washer fills and then agitates like the wash portion of the cycle. Following rinse agitation, a final spin extracts the rinse water from the clothes preparing them for the dryer.

TemperaturePressure

switchswitch

Timer

Mixing valve

Agitator

Washtub ![]()

Plastic outer tub

Transmission

Pump

Motor

RS3100007 Rev. 0 | 6 |