Disassembly Procedures

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to unit before servicing.

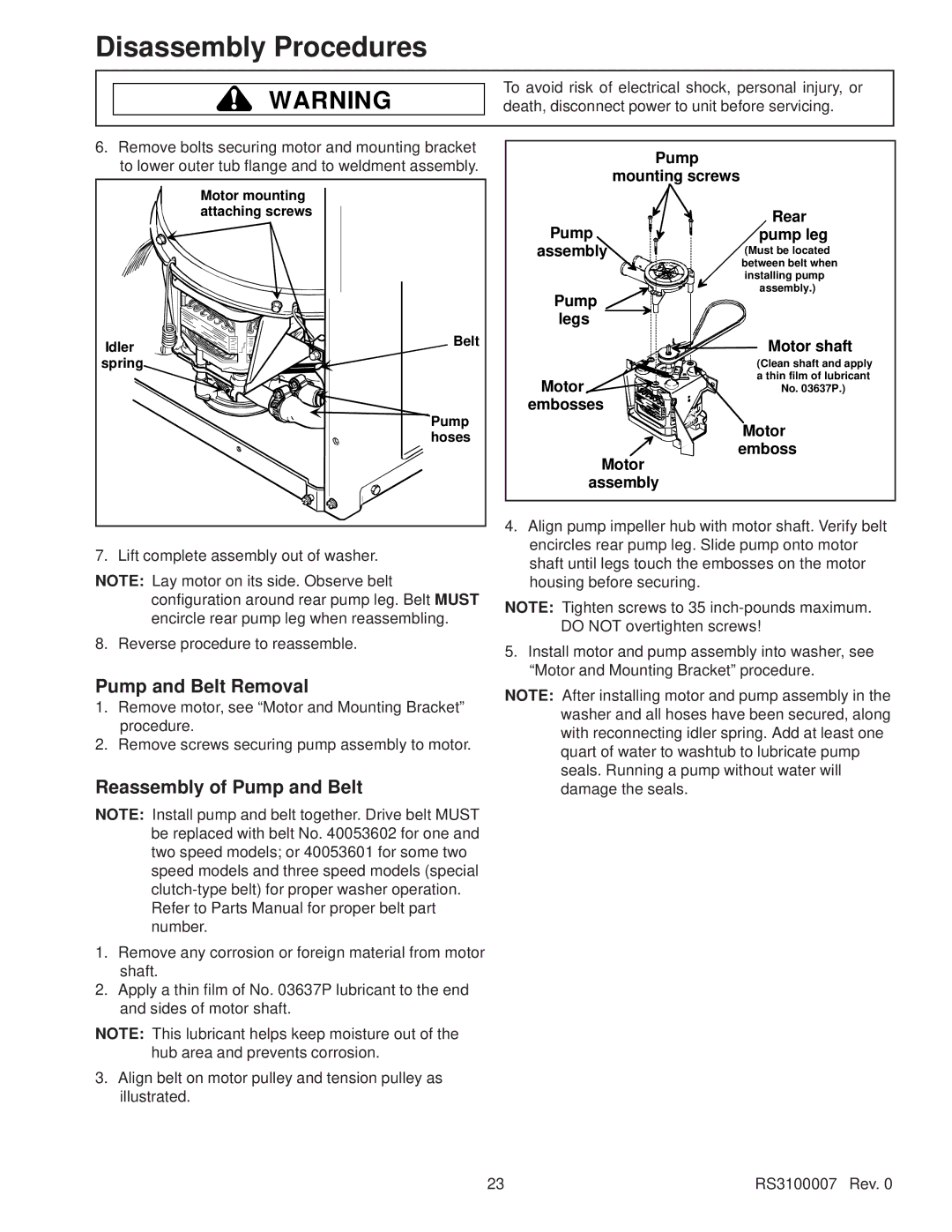

6.Remove bolts securing motor and mounting bracket to lower outer tub flange and to weldment assembly.

| Motor mounting |

| attaching screws |

Idler | Belt |

| |

spring |

|

| Pump |

| hoses |

7. Lift complete assembly out of washer.

NOTE: Lay motor on its side. Observe belt configuration around rear pump leg. Belt MUST encircle rear pump leg when reassembling.

8. Reverse procedure to reassemble.

Pump and Belt Removal

1.Remove motor, see “Motor and Mounting Bracket” procedure.

2.Remove screws securing pump assembly to motor.

Reassembly of Pump and Belt

NOTE: Install pump and belt together. Drive belt MUST be replaced with belt No. 40053602 for one and two speed models; or 40053601 for some two speed models and three speed models (special

1.Remove any corrosion or foreign material from motor shaft.

2.Apply a thin film of No. 03637P lubricant to the end and sides of motor shaft.

NOTE: This lubricant helps keep moisture out of the hub area and prevents corrosion.

3.Align belt on motor pulley and tension pulley as illustrated.

Pump |

|

mounting screws | |

Pump | Rear |

pump leg | |

assembly | (Must be located |

| between belt when |

| installing pump |

Pump | assembly.) |

| |

legs |

|

| Motor shaft |

| (Clean shaft and apply |

Motor | a thin film of lubricant |

No. 03637P.) | |

embosses |

|

| Motor |

Motor | emboss |

| |

assembly |

|

4.Align pump impeller hub with motor shaft. Verify belt encircles rear pump leg. Slide pump onto motor shaft until legs touch the embosses on the motor housing before securing.

NOTE: Tighten screws to 35

5.Install motor and pump assembly into washer, see “Motor and Mounting Bracket” procedure.

NOTE: After installing motor and pump assembly in the washer and all hoses have been secured, along with reconnecting idler spring. Add at least one quart of water to washtub to lubricate pump seals. Running a pump without water will damage the seals.

23 | RS3100007 Rev. 0 |