Disassembly Procedures

!WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to unit before servicing.

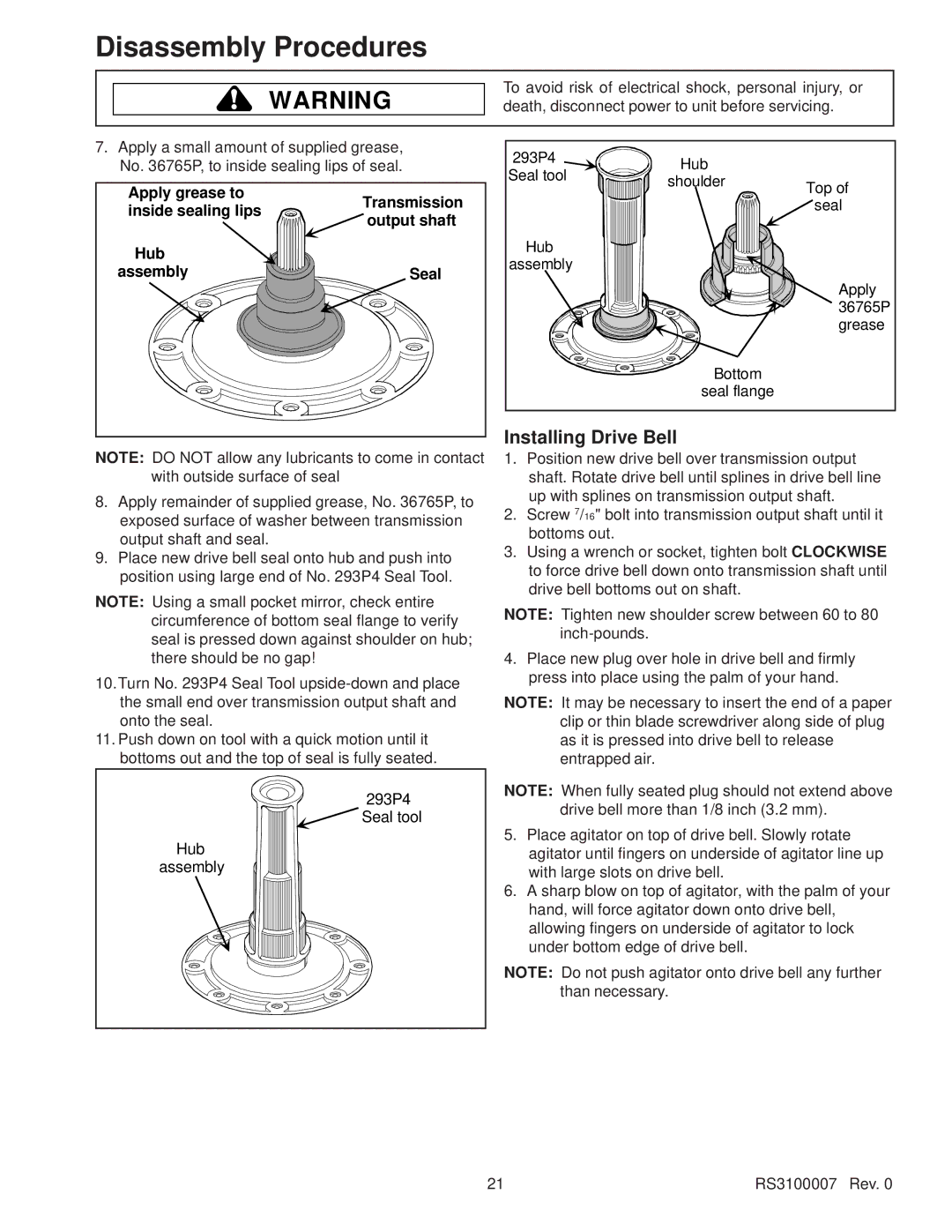

7.Apply a small amount of supplied grease, No. 36765P, to inside sealing lips of seal.

Apply grease to | Transmission | |

inside sealing lips | ||

output shaft | ||

| ||

Hub |

| |

assembly | Seal |

NOTE: DO NOT allow any lubricants to come in contact with outside surface of seal

8.Apply remainder of supplied grease, No. 36765P, to exposed surface of washer between transmission output shaft and seal.

9.Place new drive bell seal onto hub and push into position using large end of No. 293P4 Seal Tool.

NOTE: Using a small pocket mirror, check entire circumference of bottom seal flange to verify seal is pressed down against shoulder on hub; there should be no gap!

10.Turn No. 293P4 Seal Tool

11.Push down on tool with a quick motion until it bottoms out and the top of seal is fully seated.

293P4 |

Seal tool |

Hub |

assembly |

293P4 | Hub |

| |

Seal tool |

| ||

shoulder | Top of | ||

| |||

|

| ||

|

| seal | |

Hub |

|

| |

assembly |

|

| |

|

| Apply | |

|

| 36765P | |

|

| grease | |

| Bottom |

| |

| seal flange |

|

Installing Drive Bell

1.Position new drive bell over transmission output shaft. Rotate drive bell until splines in drive bell line up with splines on transmission output shaft.

2.Screw 7/16" bolt into transmission output shaft until it bottoms out.

3.Using a wrench or socket, tighten bolt CLOCKWISE to force drive bell down onto transmission shaft until drive bell bottoms out on shaft.

NOTE: Tighten new shoulder screw between 60 to 80

4.Place new plug over hole in drive bell and firmly press into place using the palm of your hand.

NOTE: It may be necessary to insert the end of a paper clip or thin blade screwdriver along side of plug as it is pressed into drive bell to release entrapped air.

NOTE: When fully seated plug should not extend above drive bell more than 1/8 inch (3.2 mm).

5.Place agitator on top of drive bell. Slowly rotate agitator until fingers on underside of agitator line up with large slots on drive bell.

6.A sharp blow on top of agitator, with the palm of your hand, will force agitator down onto drive bell, allowing fingers on underside of agitator to lock under bottom edge of drive bell.

NOTE: Do not push agitator onto drive bell any further than necessary.

21 | RS3100007 Rev. 0 |