Reconnect all cables that were removed during the disassembly procedure. Watch for single ground connections from the CRT mount to the chassis, between individual chassis members, etc., which may have lugs and screws to connect them, or sometimes individual

If practical, test the monitor and touchscreen at the earliest time possible before reassembling the display, as the reassembly of the back case can be tedious. If mistakes have been made, corrections are easier to make if the covers are still off.

Next, label the monitor with information about the touchscreen installed, along with the model and settings of any internal serial controller.

For example:

Contains

Settings: 9600/8/1/N SmartSet/Binary/Stream Mode

Finally, remove any agency certifications (UL/cUL, FCC, TÜV, CE, etc.) for which you have not resubmitted.

Sealing the Monitor

A variety of methods may be used to seal an IntelliTouch system from dust or splashed liquids as required by the application or an industry standard:

1Use only closed cell polyolefin (Volara) foam available from Elo.

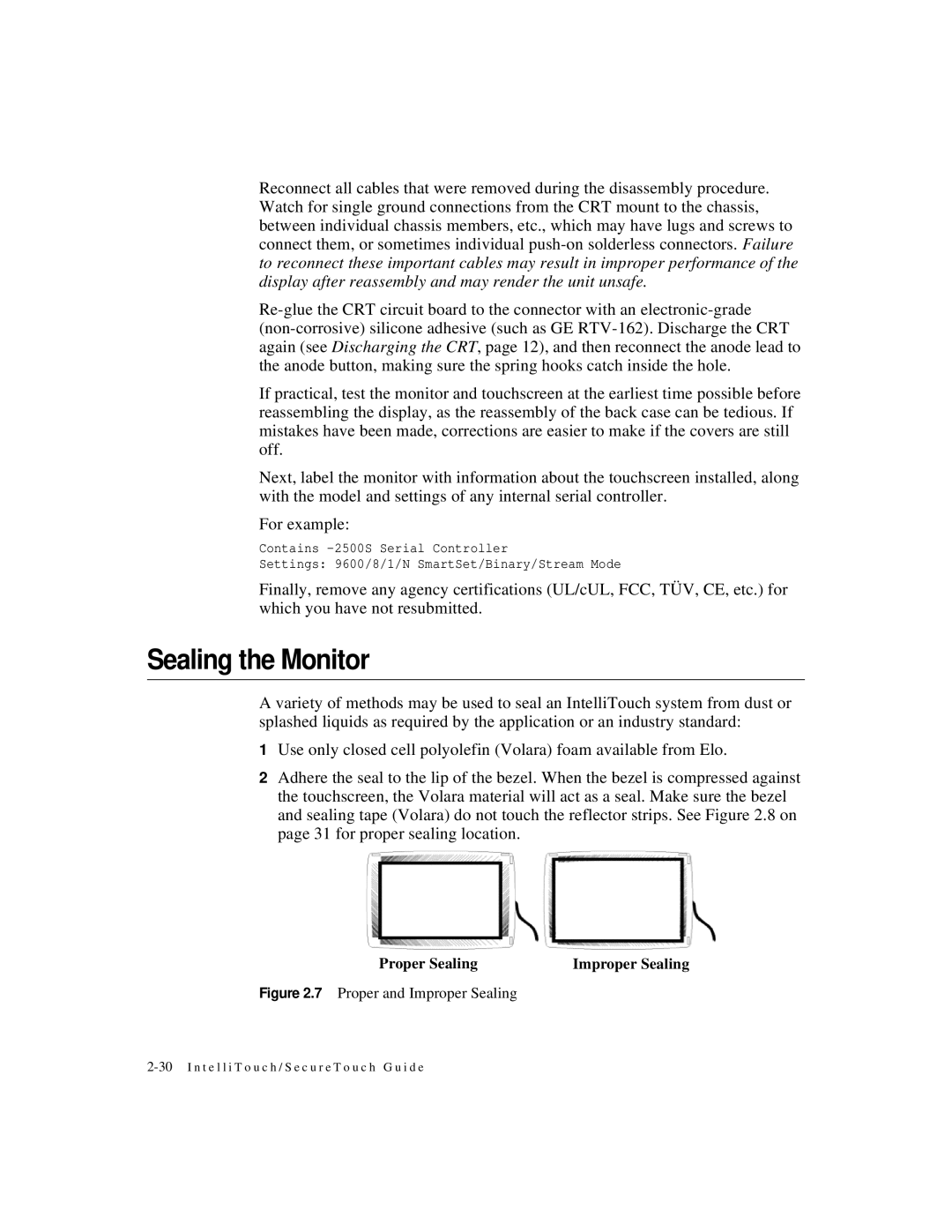

2Adhere the seal to the lip of the bezel. When the bezel is compressed against the touchscreen, the Volara material will act as a seal. Make sure the bezel and sealing tape (Volara) do not touch the reflector strips. See Figure 2.8 on page 31 for proper sealing location.

Proper Sealing | Improper Sealing |