5.Refer to the data plate on the inside of the fryer door to determine if the fryer burner is config- ured for the proper type of gas before connecting the fryer

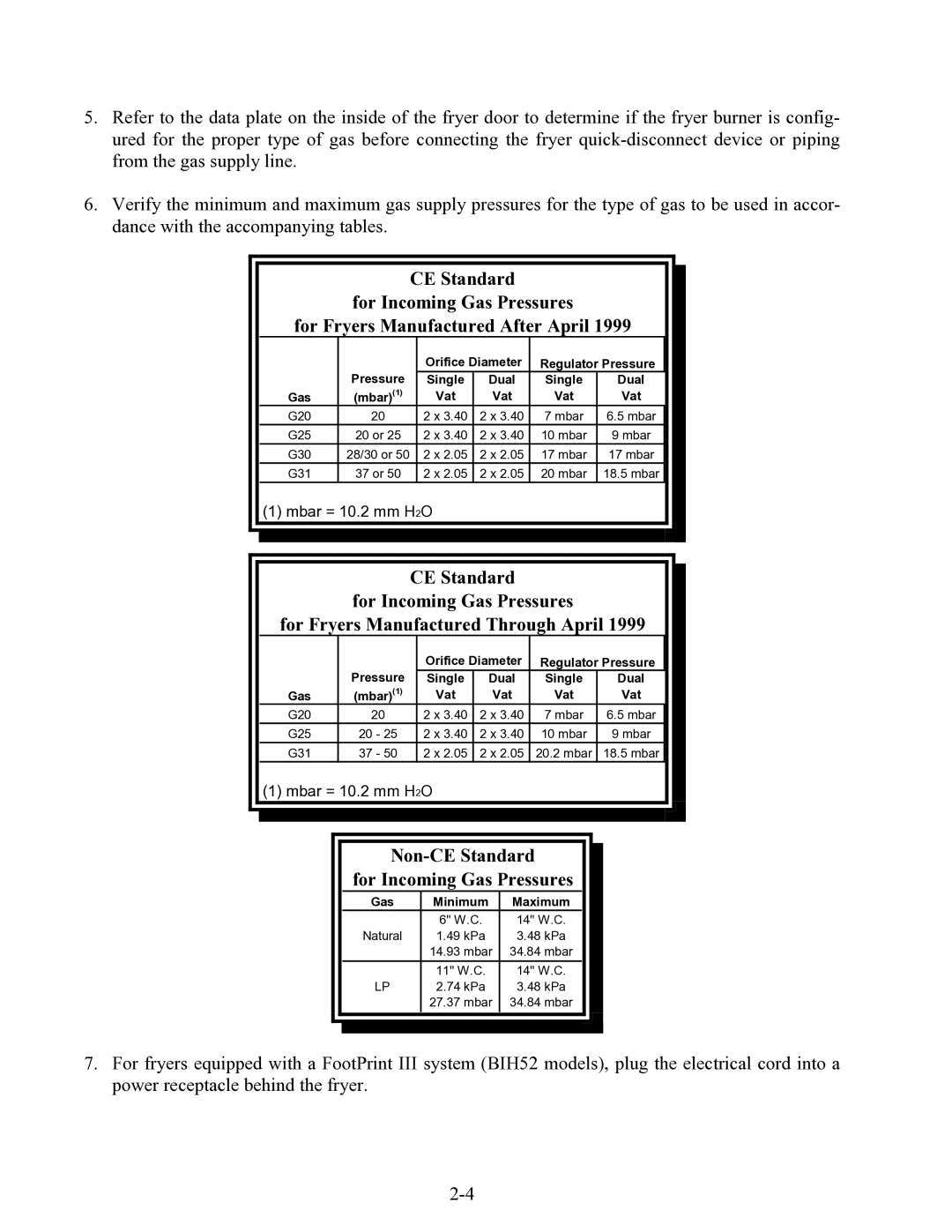

6.Verify the minimum and maximum gas supply pressures for the type of gas to be used in accor- dance with the accompanying tables.

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured After April 1999

| Pressure | Orifice Diameter | Regulator Pressure |

| ||

| Single | Dual | Single | Dual | ||

Gas | (mbar)(1) | Vat | Vat | Vat | Vat | |

G20 | 20 | 2 x 3.40 | 2 x 3.40 | 7 mbar | 6.5 mbar |

|

G25 | 20 or 25 | 2 x 3.40 | 2 x 3.40 | 10 mbar | 9 mbar |

|

G30 | 28/30 or 50 | 2 x 2.05 | 2 x 2.05 | 17 mbar | 17 mbar |

|

G31 | 37 or 50 | 2 x 2.05 | 2 x 2.05 | 20 mbar | 18.5 mbar |

|

(1) mbar = 10.2 mm H2O

CE Standard

for Incoming Gas Pressures

for Fryers Manufactured Through April 1999

| Pressure | Orifice Diameter | Regulator Pressure |

| ||

| Single | Dual | Single | Dual | ||

Gas | (mbar)(1) | Vat | Vat | Vat | Vat | |

G20 | 20 | 2 x 3.40 | 2 x 3.40 | 7 mbar | 6.5 mbar |

|

G25 | 20 - 25 | 2 x 3.40 | 2 x 3.40 | 10 mbar | 9 mbar |

|

G31 | 37 - 50 | 2 x 2.05 | 2 x 2.05 | 20.2 mbar | 18.5 mbar |

|

(1) mbar = 10.2 mm H2O

Non-CE Standard

for Incoming Gas Pressures

Gas | Minimum | Maximum |

| 6" W.C. | 14" W.C. |

Natural | 1.49 kPa | 3.48 kPa |

| 14.93 mbar | 34.84 mbar |

| 11" W.C. | 14" W.C. |

LP | 2.74 kPa | 3.48 kPa |

| 27.37 mbar | 34.84 mbar |

|

|

|

|

|

|

7.For fryers equipped with a FootPrint III system (BIH52 models), plug the electrical cord into a power receptacle behind the fryer.