Prime

Perform this procedure upon initial system setup, when- ever hoses are disconnected, if the supply hose is removed from the supply container, or if either pump is run dry. If done properly, this will prime the lines with fluid and/or remove any air bubbles from the fluid lines.

NOTE: If using an NXT air motor with DataTrak, see DataTrak Operation, page 33.

NOTE: For systems with DataTrak: When priming pumps, it is normal to get cavitation or pump runaway

alarms. Clear alarms ![]() , and press

, and press ![]() again as necessary. These alarms prevent excessive pump speeds, which will damage pump packings.

again as necessary. These alarms prevent excessive pump speeds, which will damage pump packings.

1.To enable the user to better see fluid exiting each fluid port, the front end of the RS gun can be removed. This step is optional but can be very use- ful:

a.Follow Pressure Relief Procedure and Shut- down on page 24.

b.Remove the RS gun front end. See RS gun manual list on page 3 if desired.

Operation

Oil left in the system at the factory can react with cata- lyst and create a fire or explosion.

•Flush before first use.

•Do not add catalyst to the catalyst reservoir until the system has been flushed.

2.Verify the resin suction tube is in the resin supply container. Verify catalyst pump inlet tube is properly connected to the catalyst reservoir and catalyst pump fluid inlet ball valve is open. Verify both the resin supply container and catalyst supply reservoir have adequate fluid levels.

Never allow the pump to run dry of the fluid being pumped. A dry pump quickly accelerates to a high speed, possibly damaging itself and causing overpres- surization and equipment rupture. If your pump accel- erates quickly or is running too fast, stop it immediately and check the fluid supply. If the supply container is empty and air has been pumped into the lines, refill the container and prime the pump and the lines with fluid, or flush and leave it filled with a compatible solvent. Be sure to eliminate all air from the fluid system.

3.Units with runaway protection only: enable the prime/flush function by pushing the prime/flush but- ton on the DataTrak. This prevents the DataTrak from stopping the pump if it detects a high cycle rate.

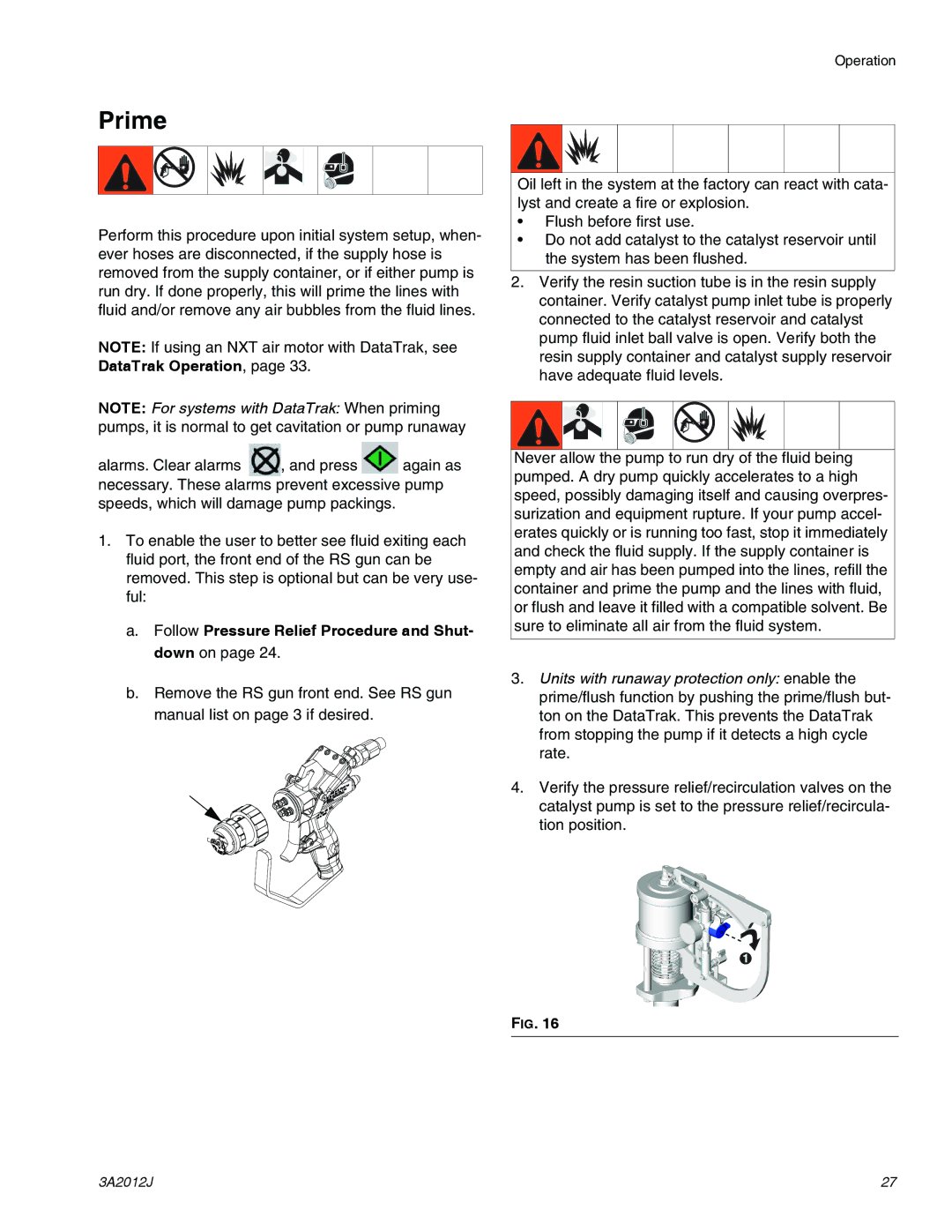

4.Verify the pressure relief/recirculation valves on the catalyst pump is set to the pressure relief/recircula- tion position.

FIG. 16

3A2012J | 27 |