Contents

Important Safety Instructions

FRP Proportioner

Contents

Agency Approvals

Related Manuals

Manual Description

Models

No Cart Cart, Mast, and Boom

Hose

Length Ratio

Accessories

Skin Injection Hazard

Toxic Fluid or Fumes Hazard

3A2012J

Important Two-Component Material Information

Material Self-ignition

Changing Materials

Keep Resin and Catalyst Components Separate

Overview

Typical Applications

Component Identification

Key

Air Control Panel

Air Motor and Resin Displacement Pump

Pressure relief/recirculation valve P relieves pres

Pressure relief/recirculation fluid outlet P1 place

Pressurized fluid outlet on filter R connect fluid

Catalyst Pump

Catalyst Pump Components

Solvent Flush Diaphragm Pump

Solvent Flush Systems

Solvent Flush Asme and CE-Approved Pressure Pot

Setup

Before Installation

Location Requirements

System Mounting Wall Mount Systems Only

For systems bolting directly to wall not using a pole

System Assembly

For cart and boom systems only, install legs

Spring Chain Roving Guides Deflector Plates

Ground Wire

Grounding

Connect Fluid and Air Lines

Air Connections

Catalyst Pump Pressure Relief Valve

Flush Before First Use

Fill Supply Tanks

Solvent Flush Connections if applicable

Gun Connections

Pressure Relief Procedure and Shutdown

Operation

Trigger Lock

Boom Operation

Operation

Startup

For internal mix proportioners only, check solvent line

Follow Pressure Relief Procedure and Shut- down on

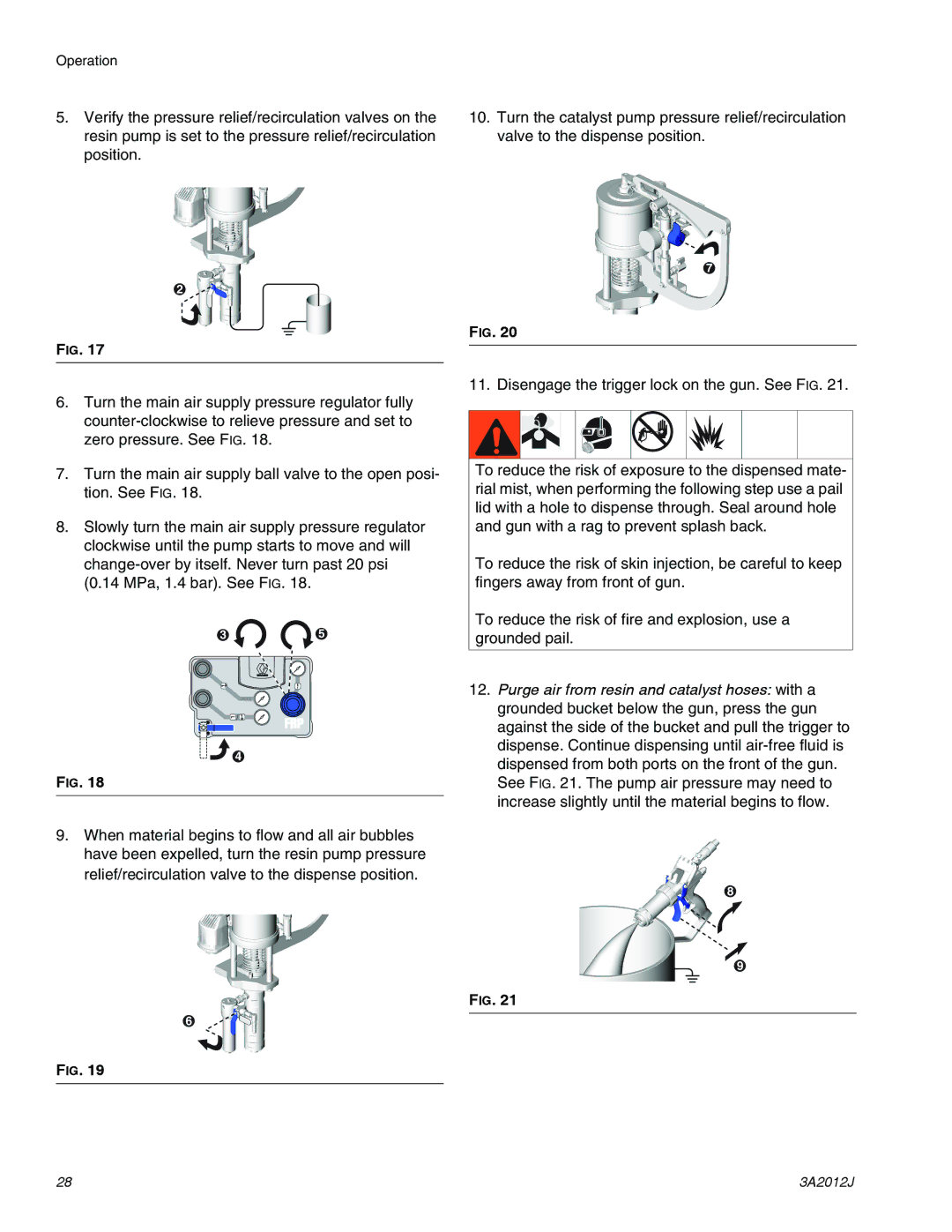

Prime

Operation

3A2012J

Flush

Spray

External mix systems 30-40 psi 0.21-0.28 MPa, 2.1-2.8 bar

AAC Air Adjustment

Follow Pressure Relief Procedure and Shutdown on

Setup Mode

Run Mode

DataTrak Operation

Operation

Runaway Monitor

Solenoid Release Button

Diagnostics

Prime/Flush

Counter/Totalizer

Display

Diagnostic Codes Symbol Code Name Diagnosis Cause

Replace DataTrak Battery or Fuse

Disconnect DataTrak

Components

Maintenance

Task Schedule Inspect pump wetcup Daily

Troubleshooting

Resin Pump

Spray pattern Mendations Fluid is too thin or too thick

Repair

Disconnect the Displacement Pump

General Information

Reconnect the Displacement Pump

Align cylinder and adapter plate

Disconnect the Air Motor

Reconnect the Air Motor

Ti18456c

Replace Pumpline

Repair Catalyst Pump

Remove Catalyst Pump from System

Disassemble Catalyst Pump

Repair Throat and Piston Seals

Repair Foot Valve

Assemble Catalyst Pump

Catalyst Pump Details

System Parts

Systems

152 24M692 SPACER, ball joint

Wall or Pole Mount KIT

Wall or Pole Mount KIT

Wall or Pole Mount KIT

Carts

Quantity

System Parts

Wall or Pole Mount Kit, 16N918

Part Description Qty

Boom, 16N761

Air Panel

Slave Pump Linkage, 16P125

Resin Pumplines

Part Description 131 171

Connecting Kit

Air Motor and Pump for Resin Pumpline

Gun

Coupling Collars

24F620

Resin Filter

Mesh Pack

Resin Supply Hose

16M736

3A2012J

Catalyst Slave Pumps

922 930 940

Installation Tools not shown

Catalyst Pumps

Catalyst Reservoir

16P425

Cart not included in kit, shown for reference only

Hose Bundles

Quantity

16N014 and 16N015 Kits

Accessory Parts Heater Kits

16N0169, 16N017, 16N018, and 16N019 Kits

Nipple

Solvent Pressure Pot Kits

Asme Pressure Pots, 2-gallon 16M893 and 5-gallon 16M894

Asme and CE-Approved Pressure Pots, 16M874 and 16M875

Tube

Solvent Diaphragm Pumps

Gallon 16M560 and 5-gallon 16M561

DataTrak Upgrade Kit

16M881

Carts for 55 Gallon Barrel, 16M896

Roving Box Bracket

16M961

Extension Hoses

Gel Hose

Chop Hose

For external gel

Cart and Boom

Dimensions

Top View

Cart Only

Wall/Pole Mount

Technical Data

Pumpline Wall Mounting Bracket Dimensions

Pumpline Technical Data

3A2012J

Graco Standard Warranty

Graco Information