Repair

Repair

•To reduce the risk of fire and explosion, repair pro- cedures must be performed in a

•Follow Pressure Relief Procedure and Shut- down on page 24 before checking or servicing the equipment.

•To prevent contact with fluids, flush the system prior to disassembling any components that con- tain catalyst or resin.

General Information

•Reference numbers and letters in parentheses in the text refer to the callouts in the figures and the parts drawing.

•Always use Genuine Graco Parts and Accessories, available from your Graco distributor. If you supply your own accessories, be sure they are adequately sized, pressure rated, and made of materials com- patible with your system.

Disconnect the Displacement Pump

See manual 3A2313 for displacement pump service and parts information.

1.Flush the pump, see page 30.

2.Stop the pump in the middle of the stroke.

3.Relieve the pressure, see page 24.

4.Disconnect the air supply and fluid hoses.

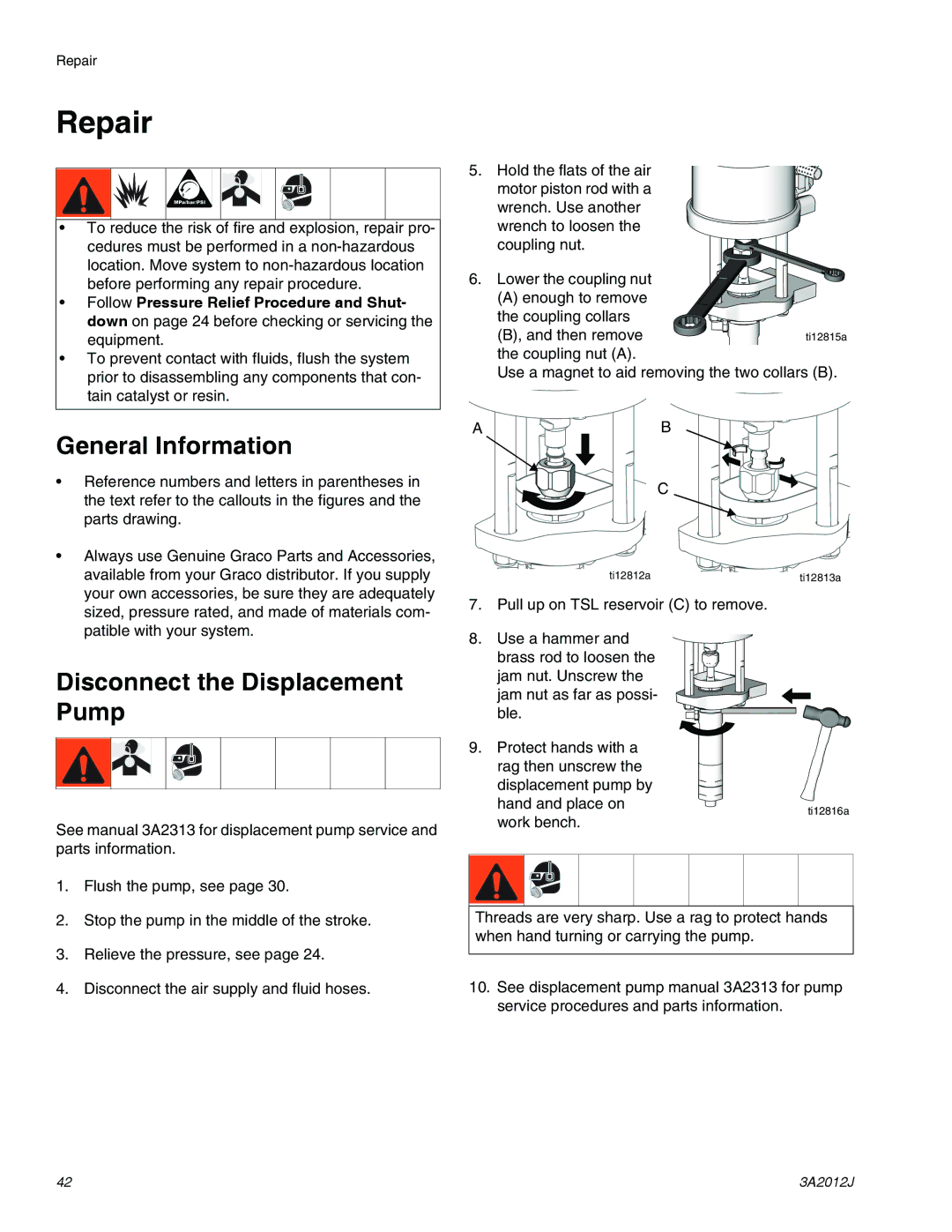

5.Hold the flats of the air motor piston rod with a wrench. Use another wrench to loosen the coupling nut.

6.Lower the coupling nut

(A) enough to remove the coupling collars

(B), and then remove | ti12815a |

the coupling nut (A). |

|

Use a magnet to aid removing the two collars (B). | |

A | B |

| C |

ti12812a | ti12813a |

7.Pull up on TSL reservoir (C) to remove.

8.Use a hammer and brass rod to loosen the jam nut. Unscrew the jam nut as far as possi- ble.

9.Protect hands with a rag then unscrew the displacement pump by

hand and place on | ti12816a | ||

work bench. | |||

| |||

|

|

| |

|

|

| |

Threads are very sharp. Use a rag to protect hands when hand turning or carrying the pump.

10.See displacement pump manual 3A2313 for pump service procedures and parts information.

42 | 3A2012J |