Spray

NOTE: If using an NXT air motor with DataTrak, see DataTrak Operation, page 33, for instructions on using

the DataTrak counter/totalizer.

Prior to production use, spray onto a clean piece of paper until all system settings are adjusted to optimize the spray pattern.

Perform this full procedure whenever the gun has been unused for an extended period of time, such as over- night. After performing this full procedure, spraying can be performed intermittently as desired by simply pulling the trigger and utilizing the trigger lock to prevent acci- dental triggering.

1.If this is the first time starting up the system, if fluid lines have been disconnected, if the fluid supply line has been removed from the supply container, or if either pump has been run dry, perform Prime pro- cedure on page 27.

2.Turn the main air supply ball valve to the closed position.

3.Turn the main air supply pressure regulator fully counterclockwise.

FIG. 25

Operation

4.Turn the resin pump pressure relief/recirculation valve to the dispense position.

FIG. 26

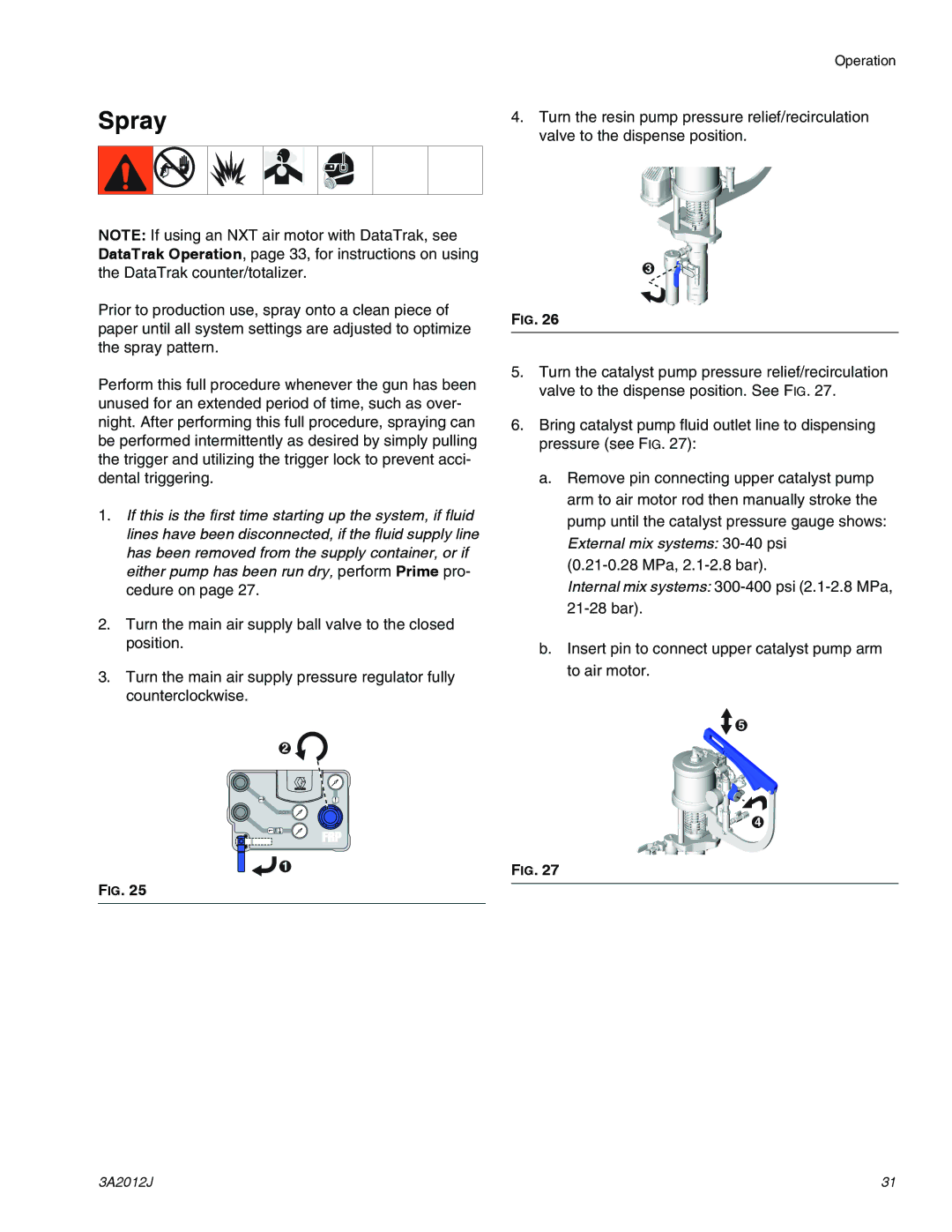

5.Turn the catalyst pump pressure relief/recirculation valve to the dispense position. See FIG. 27.

6.Bring catalyst pump fluid outlet line to dispensing pressure (see FIG. 27):

a.Remove pin connecting upper catalyst pump arm to air motor rod then manually stroke the pump until the catalyst pressure gauge shows:

External mix systems: 30-40 psi (0.21-0.28 MPa, 2.1-2.8 bar).

Internal mix systems:

b.Insert pin to connect upper catalyst pump arm to air motor.

FIG. 27

3A2012J | 31 |