2.2 Selecting the Right Paper

2.2.2Paper properties

Smoothness

Paper should have a smooth, uncoated surface. Paper with a rough or sandy surface can cause gaps in printouts. However, paper with surfaces that are too smooth may cause

Basis weight

Basis weight is the weight in pounds of 500 sheets (called a ream) of paper cut to the basic size, which is 17 × 22 inches. The number of sheets in a ream and the basic paper size relating to basis weights depend on paper classifications. In the metric system, the basis weight is expressed in grams per square meter (g/m²).

Paper that is too heavy or too light may cause misfeeds, jams, and premature wear of printer parts. Uneven weight of paper can cause

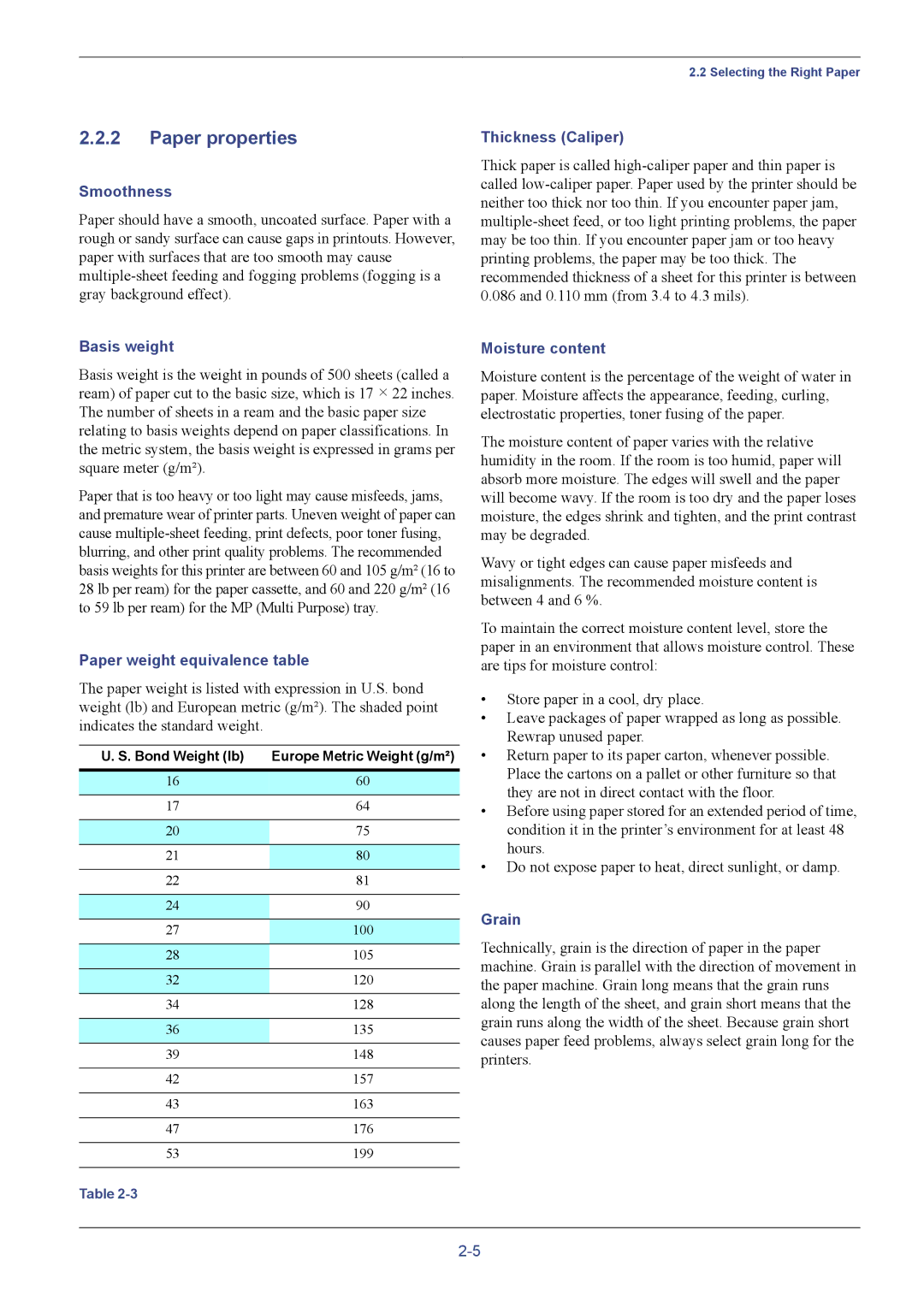

Paper weight equivalence table

The paper weight is listed with expression in U.S. bond weight (lb) and European metric (g/m²). The shaded point indicates the standard weight.

U. S. Bond Weight (lb) | Europe Metric Weight (g/m²) |

16 | 60 |

|

|

17 | 64 |

|

|

20 | 75 |

|

|

21 | 80 |

|

|

22 | 81 |

|

|

24 | 90 |

|

|

27 | 100 |

|

|

28 | 105 |

|

|

32 | 120 |

|

|

34 | 128 |

|

|

36 | 135 |

|

|

39 | 148 |

|

|

42 | 157 |

|

|

43 | 163 |

|

|

47 | 176 |

|

|

53 | 199 |

|

|

Table

Thickness (Caliper)

Thick paper is called

Moisture content

Moisture content is the percentage of the weight of water in paper. Moisture affects the appearance, feeding, curling, electrostatic properties, toner fusing of the paper.

The moisture content of paper varies with the relative humidity in the room. If the room is too humid, paper will absorb more moisture. The edges will swell and the paper will become wavy. If the room is too dry and the paper loses moisture, the edges shrink and tighten, and the print contrast may be degraded.

Wavy or tight edges can cause paper misfeeds and misalignments. The recommended moisture content is between 4 and 6 %.

To maintain the correct moisture content level, store the paper in an environment that allows moisture control. These are tips for moisture control:

•Store paper in a cool, dry place.

•Leave packages of paper wrapped as long as possible. Rewrap unused paper.

•Return paper to its paper carton, whenever possible. Place the cartons on a pallet or other furniture so that they are not in direct contact with the floor.

•Before using paper stored for an extended period of time, condition it in the printer’s environment for at least 48 hours.

•Do not expose paper to heat, direct sunlight, or damp.

Grain

Technically, grain is the direction of paper in the paper machine. Grain is parallel with the direction of movement in the paper machine. Grain long means that the grain runs along the length of the sheet, and grain short means that the grain runs along the width of the sheet. Because grain short causes paper feed problems, always select grain long for the printers.