LG Room Air Conditioner

Table of Contents

LG Model Name

2002

Code Type Code of Model Meaning

Meaning

2003~2005

Installation

Safety Precautions

There is risk of fire, electric shock, explosion, or injury

Thinner

Operation

Be cautious that water could not enter the product

Keep level even when installing the product

Operation

Symbols Used in this Manual

Dimensions

Indoor Unit

9k, 12k Btu Series

Outdoor Unit

AS-W096U0 AS-W126U0 AS-W096U1 AS-W126U1

Product Specifications

Select the best Location

Installation

Indoor unit

Outdoor unit

Fixing Installation Plate

Oil trap should be installed every 5~7 meters

Piping Length and Elevation

Flaring Work

Drill a Hole in the Wall

Check

Connecting the Piping

Indoor

Foamed polyethylene or equivalent is recom- mended

Wrap the insulation material around the connecting portion

For left rear piping

Indoor unit installation

Bad case

For left piping. Follow the instruction below Good case

Outdoor unit

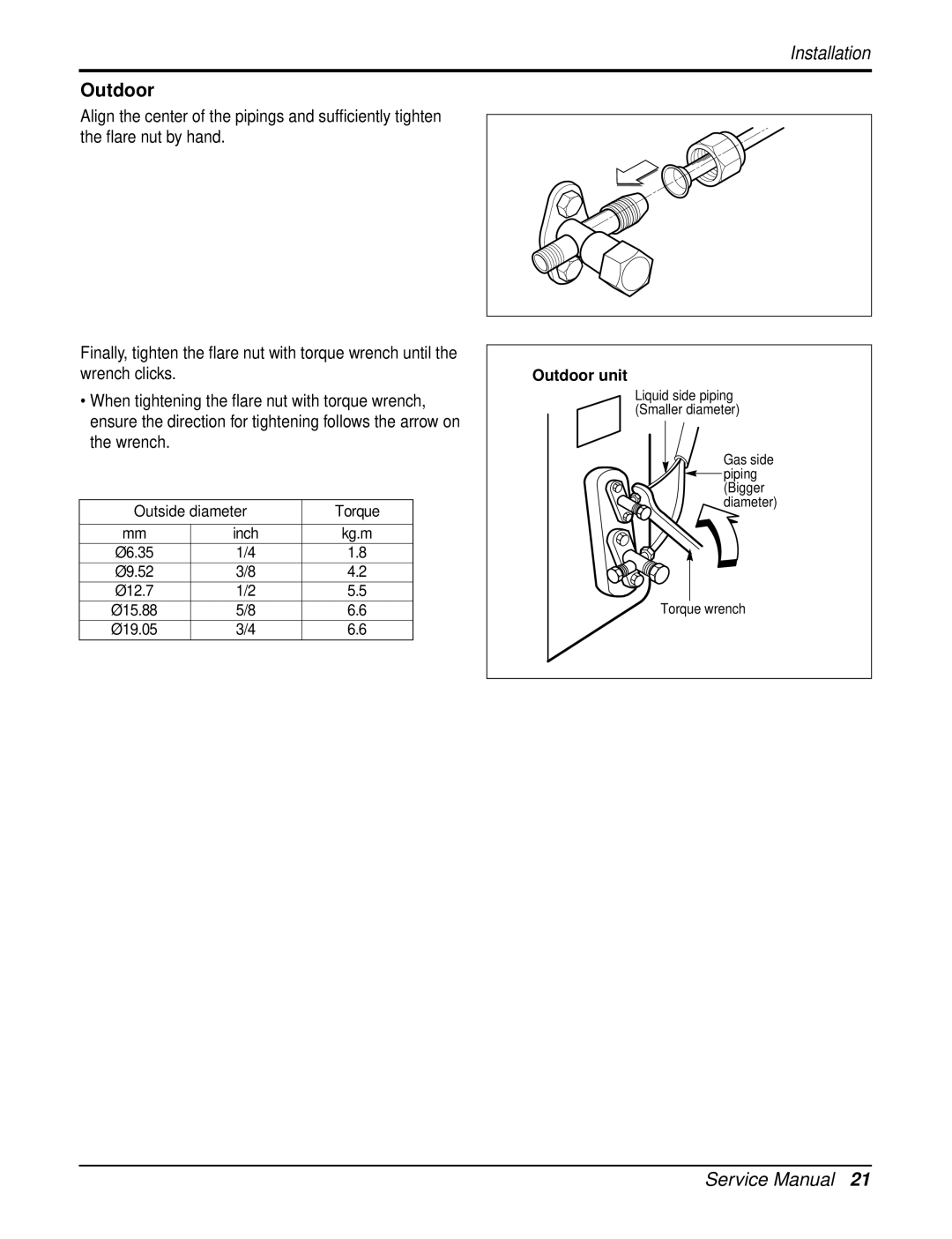

Outdoor

Connecting the Cables

Circuit Grade Breaker

Checking the Drainage

To check the drainage

Drain piping

Forming the Piping

Air Purging

Air purging

Air purging with vacuum pump

Soap water method

Evacuation

Finishing the job

Test Running

Prepare remote controller

Settlement of outdoor unit

Evaluation of the performance

Pump Down

Pump Down Procedure

Functions

Active power filter controlPSC

Power relay control

Overheatng. ProtectionPower module

Stand by control at low temp

3, 4, 5, 6 Off Timer

Cancel Sleep Mode, Timer on or Timer OFF

High39C Low11C

Cooling Down to 18C Heating Down to 16C Up to 30C

Operation

LED display of indoor unit

LG Brand/OEM Brand

Control method

Protection of the evaporator pipe from frosting

Model Comp. Operating frequency

Cooling mode operation

Intake air Temp Setting Temp

Healthy Dehumidification mode operation

Heating mode operation

Operating freq. step of comp

Temp. differences Comp. Operating frequency

Intake air temp Setting temp Fan speed

Fuzzy mode operationOptionals

Fuzzy operation for cooling

At beginning

Fuzzy operation for dehumidification

Fuzzy operation for Heating

Jet heat mode operation

Jet cool mode operation

Swing mode

Chaos swing mode

Sleep timer operation

Sleep timer operation for cooling cycle

Sleep timer operation for heating cycle

Auto restarting operation

Indoor temp Operating Mode Setting temp

Forced operation

Trial Operation

Protection from DC Peak Current

Protection from total current control

Portection from overheating of compressor

Portection from overheating of power module

Defrosting control

AS-W096/126U0 Series

AS-W096/126U1 Series

Auto Cleaning

Auto ChangeoverOptional

Low Ambient

To remove the Grille from the Chassis

Disassembly

To remove the Control Box

To remove the Discharge Grille

To remove the Evaporator

To remove the Cross-Flow Fan

To remove the Motor Cover

Schematic Diagram

Electric Control Device

IndoorAS-W096U 0, AS-W126U 0 Series

OutdoorAS-W096Series, AS-W126Series

Indoor Unit AS-W096/126U0,1 Series

Wiring Diagram

AS-W126U0 Series

Outdoor Unit AS-W096U0 Series

Components Location

Indoor Main P.W.B Assembly DC Part

Display ASSEMBLYAS-W096/126U0,1 Series

Outdoor Main P.W.B Assembly AS-W096/126U0 Series

Refrigeration Cycle Diagram

Troubleshooting Guide

Model Capillary Tube

Model Adopted Electrion Expansion Valve

Oil trap should be installed per 5~7 meters

Pipe Length and the Elevation

Outdoor unit Indoor unit

Way Valve Liquid Side

Way, 3-way Valve

Air purging

Procedure

Check for gas leakage

Purge the air from the system

Pumping Down

Air purging of the charge hose

Set the 2-way valve to the closed position

Mount the valve stem nuts and the service port nut

Re-installation

Re-air Purging

Air purging

Gas leakage

Balance Refrigerant of the 3-way Valve

All amount of refrigerant leaked

Evacuation

After Evacuation

Gas Charging

Connect the charge hose to the charging cylinder

Purge the air from the charge hose

Trouble analysis

Cycle Parts

Self-diagnosis function

Diagnosis Procedure

Precaution in Service or Check

Electronic Parts

Procedure Specification Remedy

Product doesnt operate with the remote controller

Check Point Comp. on Comp. OFF

Compressor/Outdoor Fan are unable to drive

When indoor Fan does not operate

Trouble 5 When the horizontal louver does not operate

Heater does not operate at all

Indoor Outdoor

Outdoor Unit does not operate at all

DC Peak ErrorError Code ➅

Trouble 8-1When compressor does not operate normally

Communication error between Indoor and Outdoor Error Code ➄

Trouble 8-2When compressor does not oprate normally

CT Error Error Code ➆

Trouble 8-3When compressor does not oprate normally

Problem of missing the connector Outdoor Main PCB Assy

Problem of missing the connector Indoor Main PCB Assy

Connectors Condition Problem error mode

CN-T/Block

Indoor Unit

Exploded View

Outdoor Unit

Description

Replacement Parts List

Panel ASSY, Front SUB

No A20061Z October

![]() piping (Bigger diameter)

piping (Bigger diameter)