|

|

|

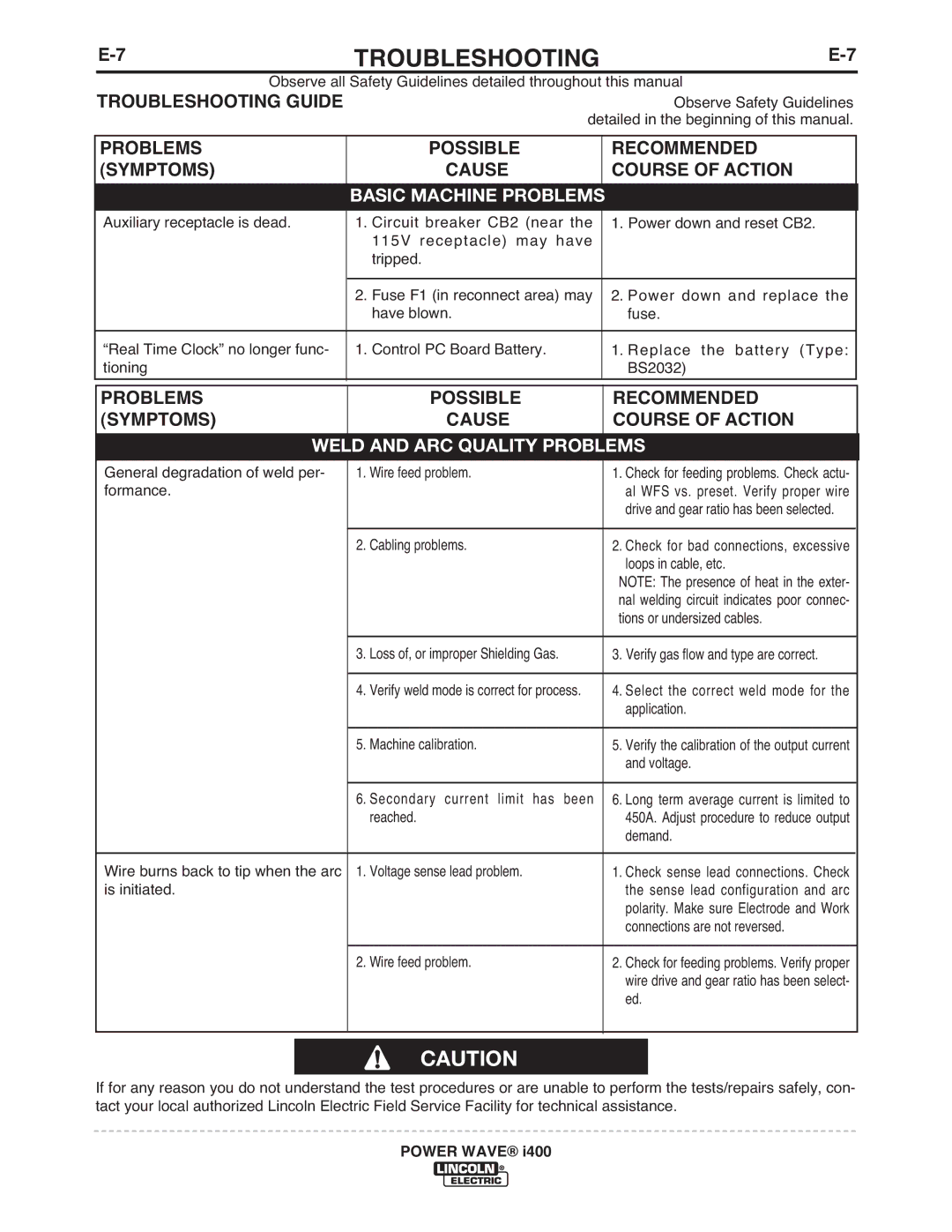

| TROUBLESHOOTING | |||||||||

|

|

| Observe all Safety Guidelines detailed throughout this manual | ||||||||||

| TROUBLESHOOTING GUIDE |

|

|

|

|

|

| Observe Safety Guidelines | |||||

|

|

|

|

|

|

| detailed in the beginning of this manual. | ||||||

| PROBLEMS |

|

| POSSIBLE |

| RECOMMENDED | |||||||

| (SYMPTOMS) |

|

| CAUSE |

| COURSE OF ACTION | |||||||

|

|

|

|

| BASIC MACHINE PROBLEMS |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| Auxiliary receptacle is dead. |

|

|

| 1. Circuit breaker CB2 (near the |

| ||||||

|

|

|

|

|

|

| 1. Power down and reset CB2. | ||||||

|

|

|

|

|

|

| 115V receptacle) may have |

|

|

|

|

|

|

|

|

|

|

|

|

| tripped. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2. Fuse F1 (in reconnect area) may |

|

|

| 2. Power down and replace the |

|

|

|

|

|

|

|

|

| have blown. |

|

|

| fuse. |

|

|

|

| “Real Time Clock” no longer func- |

|

|

| 1. Control PC Board Battery. |

|

|

| 1. Replace the battery (Type: |

|

| |

|

| tioning |

|

|

|

|

|

|

| BS2032) |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

| PROBLEMS |

|

| POSSIBLE |

| RECOMMENDED | |||||||

| (SYMPTOMS) |

|

| CAUSE |

| COURSE OF ACTION | |||||||

|

|

| WELD AND ARC QUALITY PROBLEMS | ||||||||||

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| ||||

|

| General degradation of weld per- |

| 1. Wire feed problem. | |||||||||

|

|

|

|

|

|

| 1. Check for feeding problems. Check actu- | ||||||

|

| formance. |

|

|

|

|

|

|

| al WFS vs. preset. Verify proper wire |

| ||

|

|

|

|

|

|

|

|

|

|

| drive and gear ratio has been selected. |

| |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| 2. Cabling problems. |

|

| 2. Check for bad connections, excessive |

| ||

|

|

|

|

|

|

|

|

|

|

| loops in cable, etc. |

| |

|

|

|

|

|

|

|

|

|

|

| NOTE: The presence of heat in the exter- |

| |

|

|

|

|

|

|

|

|

|

|

| nal welding circuit indicates poor connec- |

| |

|

|

|

|

|

|

|

|

|

|

| tions or undersized cables. |

| |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| 3. Loss of, or improper Shielding Gas. |

|

| 3. Verify gas flow and type are correct. |

| ||

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| 4. Verify weld mode is correct for process. |

|

| 4. Select the correct weld mode for the |

| ||

|

|

|

|

|

|

|

|

|

|

| application. |

| |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| 5. Machine calibration. |

|

| 5. Verify the calibration of the output current |

| ||

|

|

|

|

|

|

|

|

|

|

| and voltage. |

| |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| 6. Secondary current limit has been |

|

| 6. Long term average current is limited to |

| ||

|

|

|

|

|

|

| reached. |

| 450A. Adjust procedure to reduce output |

| |||

|

|

|

|

|

|

|

|

|

|

| demand. |

| |

|

|

|

|

|

|

|

|

|

| ||||

|

| Wire burns back to tip when the arc |

|

|

| 1. Voltage sense lead problem. |

|

| 1. Check sense lead connections. Check |

| |||

|

| is initiated. |

|

|

|

|

|

|

| the sense lead configuration and arc |

| ||

|

|

|

|

|

|

|

|

|

|

| polarity. Make sure Electrode and Work |

| |

|

|

|

|

|

|

|

|

|

|

| connections are not reversed. |

| |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| 2. Wire feed problem. |

|

| 2. Check for feeding problems. Verify proper |

| ||

|

|

|

|

|

|

|

|

|

|

| wire drive and gear ratio has been select- |

| |

|

|

|

|

|

|

|

|

|

|

| ed. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con- tact your local authorized Lincoln Electric Field Service Facility for technical assistance.

POWER WAVE® i400