|

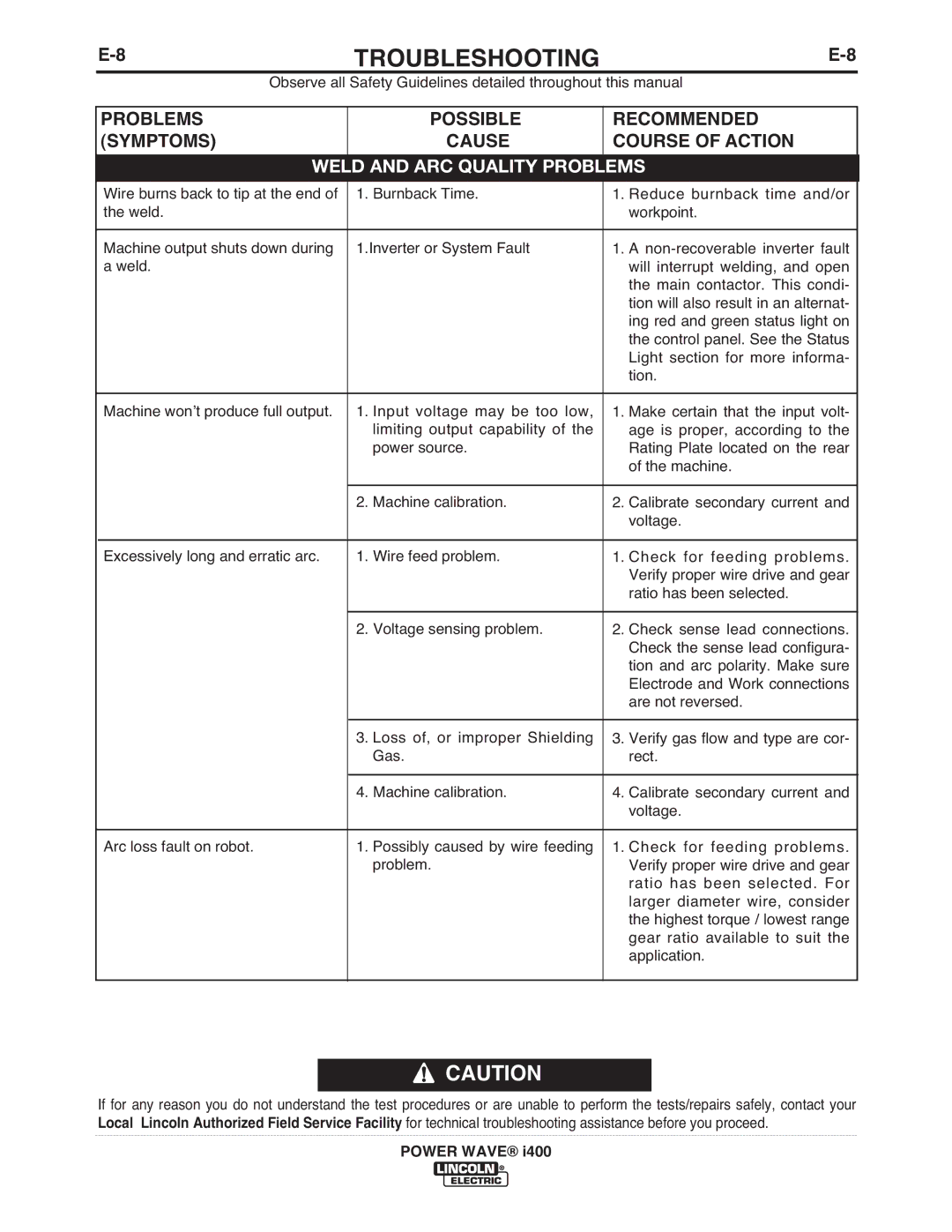

| TROUBLESHOOTING |

|

| ||||||

|

| Observe all Safety Guidelines detailed throughout this manual | ||||||||

|

|

|

|

|

|

|

|

| ||

PROBLEMS |

| POSSIBLE |

| RECOMMENDED | ||||||

(SYMPTOMS) |

| CAUSE |

| COURSE OF ACTION | ||||||

|

| WELD AND ARC QUALITY PROBLEMS | ||||||||

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| |

| Wire burns back to tip at the end of | 1. Burnback Time. | ||||||||

|

|

|

| 1. | Reduce burnback time and/or | |||||

| the weld. |

|

|

|

|

|

| workpoint. |

| |

| Machine output shuts down during |

|

| 1.Inverter or System Fault |

|

| 1. | A |

| |

| a weld. |

|

|

|

|

|

| will interrupt welding, and open |

| |

|

|

|

|

|

|

|

|

| the main contactor. This condi- |

|

|

|

|

|

|

|

|

|

| tion will also result in an alternat- |

|

|

|

|

|

|

|

|

|

| ing red and green status light on |

|

|

|

|

|

|

|

|

|

| the control panel. See the Status |

|

|

|

|

|

|

|

|

|

| Light section for more informa- |

|

|

|

|

|

|

|

|

|

| tion. |

|

| Machine wonʼt produce full output. |

|

| 1. Input voltage may be too low, |

|

| 1. | Make certain that the input volt- |

| |

|

|

|

|

| limiting output capability of the |

|

|

| age is proper, according to the |

|

|

|

|

|

| power source. |

|

|

| Rating Plate located on the rear |

|

|

|

|

|

|

|

|

|

| of the machine. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2. Machine calibration. |

|

| 2. | Calibrate secondary current and |

|

|

|

|

|

|

|

|

|

| voltage. |

|

|

|

|

|

|

|

|

|

|

| |

| Excessively long and erratic arc. |

|

| 1. Wire feed problem. |

|

| 1. | Check for feeding problems. |

| |

|

|

|

|

|

|

|

|

| Verify proper wire drive and gear |

|

|

|

|

|

|

|

|

|

| ratio has been selected. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2. Voltage sensing problem. |

|

| 2. | Check sense lead connections. |

|

|

|

|

|

|

|

|

|

| Check the sense lead configura- |

|

|

|

|

|

|

|

|

|

| tion and arc polarity. Make sure |

|

|

|

|

|

|

|

|

|

| Electrode and Work connections |

|

|

|

|

|

|

|

|

|

| are not reversed. |

|

|

|

|

|

| 3. Loss of, or improper Shielding |

|

| 3. | Verify gas flow and type are cor- |

|

|

|

|

|

| Gas. |

|

|

| rect. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4. Machine calibration. |

|

| 4. | Calibrate secondary current and |

|

|

|

|

|

|

|

|

|

| voltage. |

|

|

|

|

|

|

|

|

|

|

| |

| Arc loss fault on robot. |

|

| 1. Possibly caused by wire feeding |

|

| 1. | Check for feeding problems. |

| |

|

|

|

|

| problem. |

|

|

| Verify proper wire drive and gear |

|

|

|

|

|

|

|

|

|

| ratio has been selected. For |

|

|

|

|

|

|

|

|

|

| larger diameter wire, consider |

|

|

|

|

|

|

|

|

|

| the highest torque / lowest range |

|

|

|

|

|

|

|

|

|

| gear ratio available to suit the |

|

|

|

|

|

|

|

|

|

| application. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER WAVE® i400