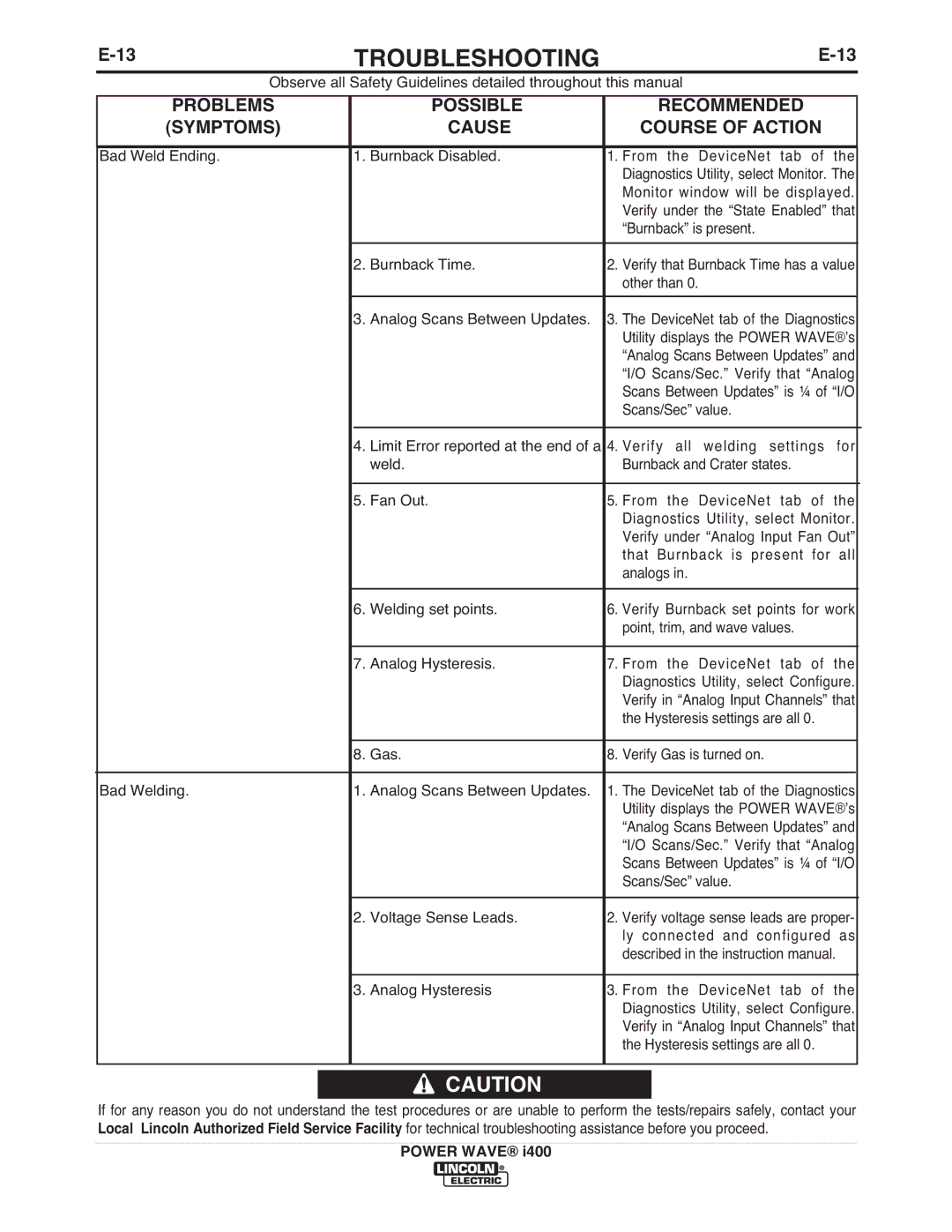

TROUBLESHOOTING | ||

| Observe all Safety Guidelines detailed throughout this manual |

|

PROBLEMS

(SYMPTOMS)

POSSIBLE

CAUSE

RECOMMENDED

COURSE OF ACTION

Bad Weld Ending. | 1. Burnback Disabled. | 1. From the DeviceNet tab of the |

| |||

|

|

|

|

| Diagnostics Utility, select Monitor. The |

|

|

|

|

|

| Monitor window will be displayed. |

|

|

|

|

|

| Verify under the “State Enabled” that |

|

|

|

|

|

| “Burnback” is present. |

|

| 2. | Burnback Time. | 2. | Verify that Burnback Time has a value |

| |

|

|

|

|

| other than 0. |

|

| 3. | Analog Scans Between Updates. | 3. | The DeviceNet tab of the Diagnostics |

| |

|

|

|

|

| Utility displays the POWER WAVE®ʼs |

|

|

|

|

|

| “Analog Scans Between Updates” and |

|

|

|

|

|

| “I/O Scans/Sec.” Verify that “Analog |

|

|

|

|

|

| Scans Between Updates” is ¼ of “I/O |

|

|

|

|

|

| Scans/Sec” value. |

|

|

|

|

|

|

|

|

| 4. | Limit Error reported at the end of a | 4. | Verify all welding settings for |

| |

|

|

| weld. |

| Burnback and Crater states. |

|

|

|

|

|

|

| |

| 5. | Fan Out. | 5. | From the DeviceNet tab of the |

| |

|

|

|

|

| Diagnostics Utility, select Monitor. |

|

|

|

|

|

| Verify under “Analog Input Fan Out” |

|

|

|

|

|

| that Burnback is present for all |

|

|

|

|

|

| analogs in. |

|

| 6. | Welding set points. | 6. | Verify Burnback set points for work |

| |

|

|

|

|

| point, trim, and wave values. |

|

|

|

|

|

|

| |

| 7. | Analog Hysteresis. | 7. | From the DeviceNet tab of the |

| |

|

|

|

|

| Diagnostics Utility, select Configure. |

|

|

|

|

|

| Verify in “Analog Input Channels” that |

|

|

|

|

|

| the Hysteresis settings are all 0. |

|

|

|

|

|

|

| |

| 8. | Gas. | 8. | Verify Gas is turned on. |

| |

|

|

|

|

| ||

Bad Welding. | 1. Analog Scans Between Updates. | 1. | The DeviceNet tab of the Diagnostics |

| ||

|

|

|

|

| Utility displays the POWER WAVE®ʼs |

|

|

|

|

|

| “Analog Scans Between Updates” and |

|

|

|

|

|

| “I/O Scans/Sec.” Verify that “Analog |

|

|

|

|

|

| Scans Between Updates” is ¼ of “I/O |

|

|

|

|

|

| Scans/Sec” value. |

|

| 2. | Voltage Sense Leads. | 2. | Verify voltage sense leads are proper- |

| |

|

|

|

|

| ly connected and configured as |

|

|

|

|

|

| described in the instruction manual. |

|

|

|

|

|

|

| |

| 3. | Analog Hysteresis | 3. | From the DeviceNet tab of the |

| |

|

|

|

|

| Diagnostics Utility, select Configure. |

|

|

|

|

|

| Verify in “Analog Input Channels” that |

|

|

|

|

|

| the Hysteresis settings are all 0. |

|

|

|

|

|

|

|

|

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER WAVE® i400