|

|

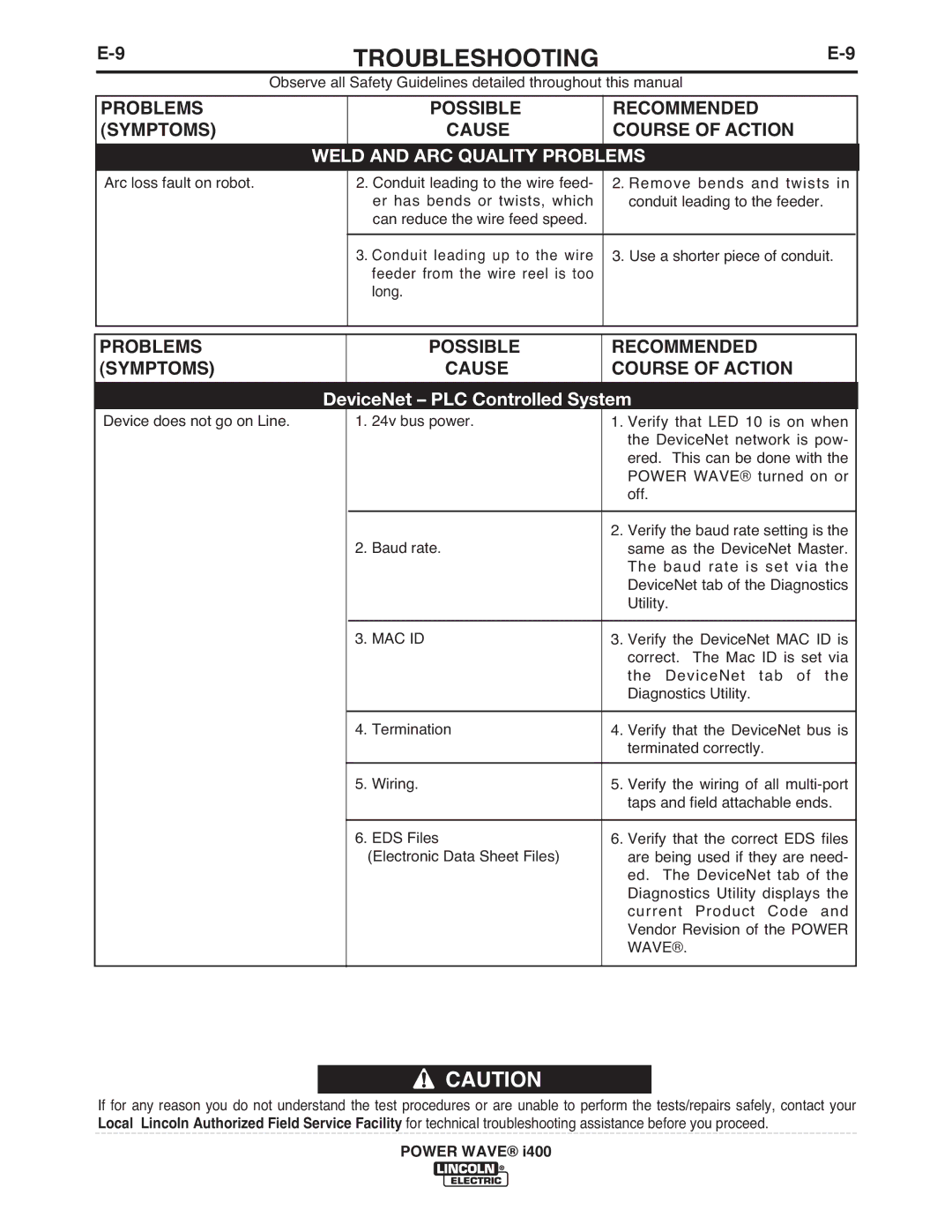

| TROUBLESHOOTING |

|

| |||||||||

| Observe all Safety Guidelines detailed throughout this manual | |||||||||||||

PROBLEMS |

|

|

|

|

| POSSIBLE |

|

| RECOMMENDED | |||||

(SYMPTOMS) |

|

|

|

|

| CAUSE |

|

| COURSE OF ACTION | |||||

|

| WELD AND ARC QUALITY PROBLEMS | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Arc loss fault on robot. |

|

|

| 2. Conduit leading to the wire feed- |

| ||||||||

|

|

|

|

|

|

|

|

| 2. Remove bends and twists in | |||||

|

|

|

|

|

|

| er has bends or twists, which |

|

|

| conduit leading to the feeder. |

| ||

|

|

|

|

|

|

| can reduce the wire feed speed. |

|

|

|

|

|

| |

|

|

|

|

|

|

| 3. Conduit leading up to the wire |

|

|

| 3. Use a shorter piece of conduit. |

| ||

|

|

|

|

|

|

| feeder from the wire reel is too |

|

|

|

|

|

| |

|

|

|

|

|

|

| long. |

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

PROBLEMS |

|

|

|

|

| POSSIBLE |

|

| RECOMMENDED | |||||

(SYMPTOMS) |

|

|

|

|

| CAUSE |

|

| COURSE OF ACTION | |||||

|

| DeviceNet – PLC Controlled System | ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Device does not go on Line. |

|

|

|

|

| 1. 24v bus power. |

|

| |||||

|

|

|

|

|

|

|

|

|

| 1. Verify that LED 10 is on when | ||||

|

|

|

|

|

|

|

|

|

|

|

| the DeviceNet network is pow- |

| |

|

|

|

|

|

|

|

|

|

|

|

| ered. This can be done with the |

| |

|

|

|

|

|

|

|

|

|

|

|

| POWER WAVE® turned on or |

| |

|

|

|

|

|

|

|

|

|

|

|

| off. |

| |

|

|

|

|

|

|

| 2. Baud rate. |

|

|

|

| 2. Verify the baud rate setting is the |

|

|

|

|

|

|

|

|

|

|

|

| same as the DeviceNet Master. |

| |||

|

|

|

|

|

|

|

|

|

|

|

| The baud rate is set via the |

| |

|

|

|

|

|

|

|

|

|

|

|

| DeviceNet tab of the Diagnostics |

| |

|

|

|

|

|

|

|

|

|

|

|

| Utility. |

| |

|

|

|

|

|

|

| 3. MAC ID |

|

|

|

| 3. Verify the DeviceNet MAC ID is |

|

|

|

|

|

|

|

|

|

|

|

|

|

| correct. The Mac ID is set via |

| |

|

|

|

|

|

|

|

|

|

|

|

| the DeviceNet tab of the |

| |

|

|

|

|

|

|

|

|

|

|

|

| Diagnostics Utility. |

| |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| 4. Termination |

|

|

|

| 4. Verify that the DeviceNet bus is |

|

|

|

|

|

|

|

|

|

|

|

|

|

| terminated correctly. |

| |

|

|

|

|

|

|

| 5. Wiring. |

|

|

|

| 5. Verify the wiring of all |

|

|

|

|

|

|

|

|

|

|

|

|

|

| taps and field attachable ends. |

| |

|

|

|

|

|

|

| 6. EDS Files |

|

|

|

| 6. Verify that the correct EDS files |

|

|

|

|

|

|

|

|

| (Electronic Data Sheet Files) |

|

|

| are being used if they are need- |

| ||

|

|

|

|

|

|

|

|

|

|

|

| ed. The DeviceNet tab of the |

| |

|

|

|

|

|

|

|

|

|

|

|

| Diagnostics Utility displays the |

| |

|

|

|

|

|

|

|

|

|

|

|

| current Product Code and |

| |

|

|

|

|

|

|

|

|

|

|

|

| Vendor Revision of the POWER |

| |

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

| WAVE®. |

| |

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER WAVE® i400