OPERATION |

2. THERMAL INDICATOR (THERMAL OVERLOAD): A yellow light that comes on when an over temperature sit- uation occurs. Output is disabled and the fan continues to run, until the machine cools down. When cool, the light goes out and output is enabled.

3. CIRCUIT BREAKER (CB1 - 15 AMP): Protects the 40

volt DC supply for the feeder and machine controls.

4. VOLTAGE SENSE CONNECTOR: Allows for separate

remote electrode and work sense leads.

Pin | Leads |

| Function |

3 | 21 |

| Work Voltage Sense |

1 | 67C |

| Electrode Voltage Sense |

5. OPTIONAL | DEVICENET | OR | |

CONNECTOR: Available as optional kits to support either DeviceNet communication, or synchronized tandem pulse welding. These options cannot coexist.

DEVICENET CONNECTOR (5 PIN - SEALED MINI STYLE):

Pin | Lead |

|

| Function |

2 | 894 |

| +24 VDC DeviceNet | |

3 | 893 |

| Common DeviceNet | |

4 | 892 |

|

| DeviceNet H |

5 | 891 |

|

| DeviceNet L |

| ||||

Pin | Lead |

| Function | |

A | White |

| “Ready” H | |

B | Black/White |

| “Ready” L | |

C | Green |

| “Kill” H | |

D | Black/Green |

| “Kill” L | |

6.ETHERNET CONNECTOR

Pin | Function |

1 | Transmit + |

2 | Transmit - |

3 | Receive + |

4 | |

5 | |

6 | Receive - |

7 | |

8 |

7.WIRE FEEDER RECEPTACLE

Pin | Leads | Function | |

A | 539 | Motor + | |

B | 541 | Motor - |

|

C | 521 | Solenoid + |

|

D | 522 | Solenoid Common |

|

E | 845 | Tach 2A differential signal |

|

F | 847 | Single Tach input | ||

G | 841 | +15V Tach supply |

| |

H | 844 | Tach common |

| |

I | Open | Reserved for future use |

| |

J |

| Shielding drain |

| |

K | 842 | Tach 1A differential signal |

| |

L | 843 | Tach 1B differential signal |

| |

M | 846 | Tach 2B differential signal |

| |

N | 67A / 67B | Electrode Voltage Sense |

| |

8.NEGATIVE OUTPUT TERMINAL

9.POSITIVE OUTPUT TERMINAL

10.ARCLINK® RECEPTACLE:

Pin | Leads | Function |

A | 153A / 153B | Communication Bus L |

B | 154A / 154B | Communication Bus H |

C | 67B / 67C | Electrode Voltage Sense |

D | 52 / 52A | +40V DC |

E | 51 / 51A | 0 VDC |

11.ON / OFF SWITCH: Controls input power to the POWER WAVE® i400, and when properly inte- grated, the Fanuc R30iA Controller.

![]() WARNING

WARNING

The POWER WAVE® i400 ON/OFF switch is NOT intended as a Service Disconnect for this equip- ment.

12. FEEDER STATUS INDICATOR (See Item 1)

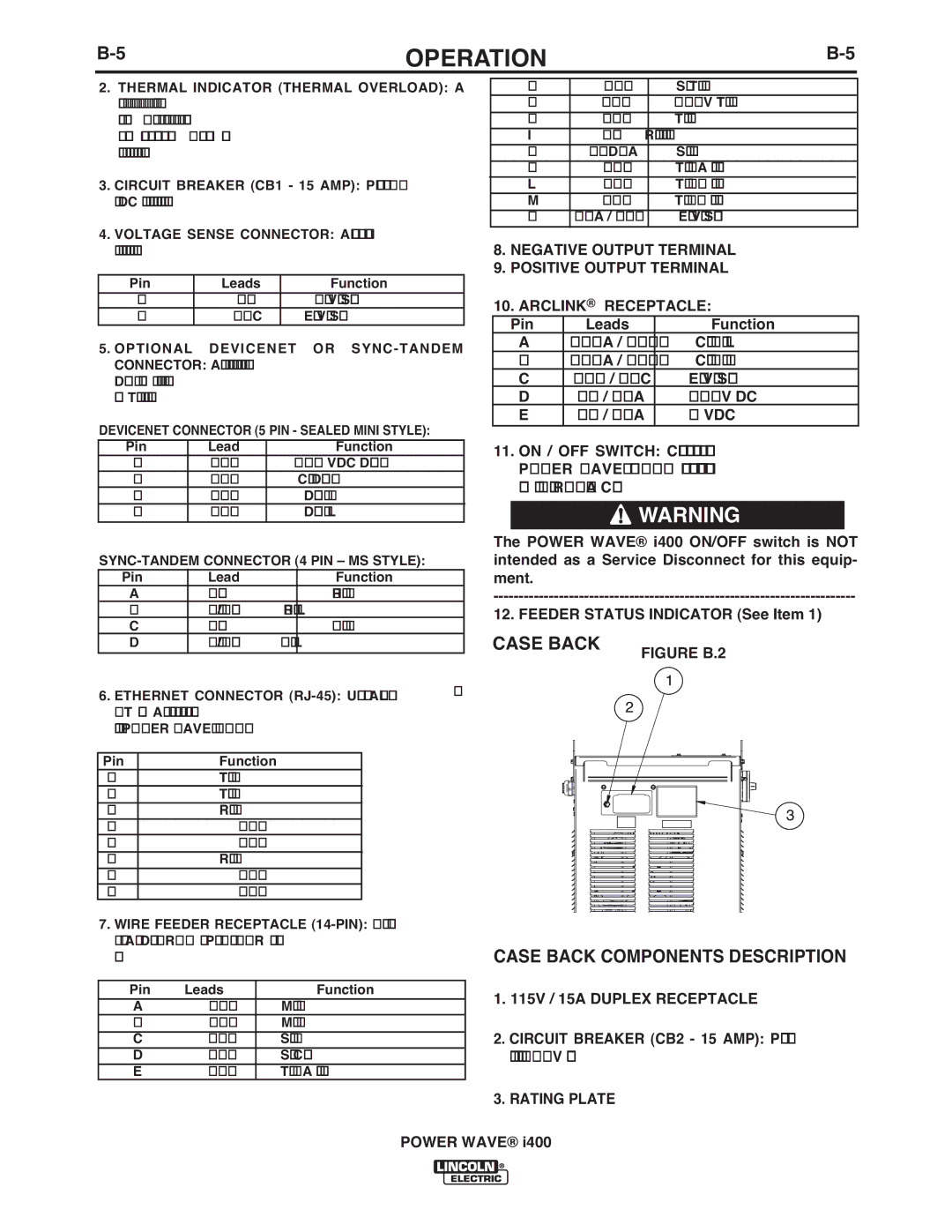

CASE BACK

FIGURE B.2

1

2

3

CASE BACK COMPONENTS DESCRIPTION

1.115V / 15A DUPLEX RECEPTACLE

2.CIRCUIT BREAKER (CB2 - 15 AMP): Provides pro- tection for the 115V auxiliary.

3.RATING PLATE

POWER WAVE® i400