to Section TOC

to Master TOC

OPERATION

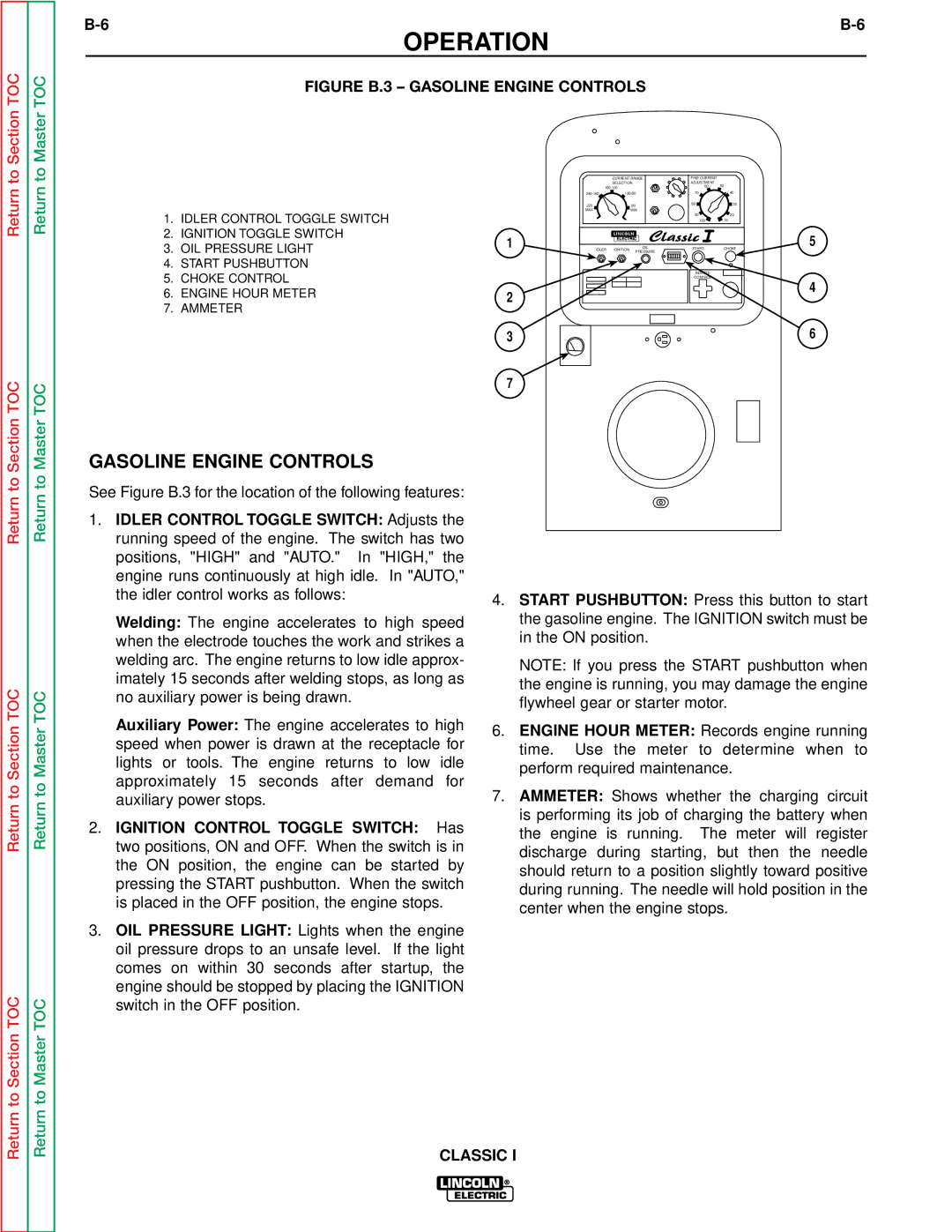

FIGURE B.3 – GASOLINE ENGINE CONTROLS

1. | IDLER CONTROL TOGGLE SWITCH |

| |

2. | IGNITION TOGGLE SWITCH | 1 | |

3. | OIL PRESSURE LIGHT | ||

|

4.START PUSHBUTTON

5.CHOKE CONTROL

6. | ENGINE HOUR METER | 2 |

7. | AMMETER |

|

3

7

| CURRENT RANGE | FINE CURRENT |

| |

| SELECTION | ADJUSTMENT | 50 | |

| 60 | |||

70 | 40 | |||

220 |

| 90 | 80 | 30 |

MAX |

| MIN |

|

|

|

|

| 90 | 20 |

|

|

| 100 | 10 |

IDLER | IGNITION | OIL | START | 5 |

PRESSURE | CHOKE | |||

|

|

| REMOTE |

|

|

|

| CONTROL |

|

4

6

Return to

Return to Section TOC

Return to Section TOC

Return to

Return to Master TOC

Return to Master TOC

GASOLINE ENGINE CONTROLS

See Figure B.3 for the location of the following features:

1.IDLER CONTROL TOGGLE SWITCH: Adjusts the running speed of the engine. The switch has two positions, "HIGH" and "AUTO." In "HIGH," the engine runs continuously at high idle. In "AUTO," the idler control works as follows:

Welding: The engine accelerates to high speed when the electrode touches the work and strikes a welding arc. The engine returns to low idle approx- imately 15 seconds after welding stops, as long as no auxiliary power is being drawn.

Auxiliary Power: The engine accelerates to high speed when power is drawn at the receptacle for lights or tools. The engine returns to low idle approximately 15 seconds after demand for auxiliary power stops.

2.IGNITION CONTROL TOGGLE SWITCH: Has two positions, ON and OFF. When the switch is in the ON position, the engine can be started by pressing the START pushbutton. When the switch is placed in the OFF position, the engine stops.

3.OIL PRESSURE LIGHT: Lights when the engine oil pressure drops to an unsafe level. If the light comes on within 30 seconds after startup, the engine should be stopped by placing the IGNITION switch in the OFF position.

4.START PUSHBUTTON: Press this button to start the gasoline engine. The IGNITION switch must be in the ON position.

NOTE: If you press the START pushbutton when the engine is running, you may damage the engine flywheel gear or starter motor.

6.ENGINE HOUR METER: Records engine running time. Use the meter to determine when to perform required maintenance.

7.AMMETER: Shows whether the charging circuit is performing its job of charging the battery when the engine is running. The meter will register discharge during starting, but then the needle should return to a position slightly toward positive during running. The needle will hold position in the center when the engine stops.