DRIVE MOTOR

The drive motor is still a switched reluc- tance type motor. (For more information, please refer to manual 16008373, Sec- tion 4; Drive Motor.)

The new motor is a sensorless motor drive system. The word "sensorless" indicates that motor direction and speed detection are performed electrically without the aid of the sending device. Meaning, the sensor was eliminated from the end of the motor along with the wire harness leading to the RPT connection on the motor control board.

MOTOR CONTROL BOARD

The motor control is able to determine the motor's position by monitoring the active phases in the motor. This is done by sending pulse signals to the motor and then timing the echo signal. By doing this, the motor control is able to deterimine the motor speed and direction. This information is then calculated to deter- mine the motor speed.

The motor control has a software switch in it that will turn off all power devices for as long as the main voltage is above 133 VAC. Once the mains voltage drops below that voltage, the power devices will be

Motor Control Access

Slight modifications were made to the motor control bracket and the plastic drip shield.

Drip Shield Removal

1.Push the plastic shield on either side of the locking tab to buckle and unlock the shield from the motor control bracket. (Figure

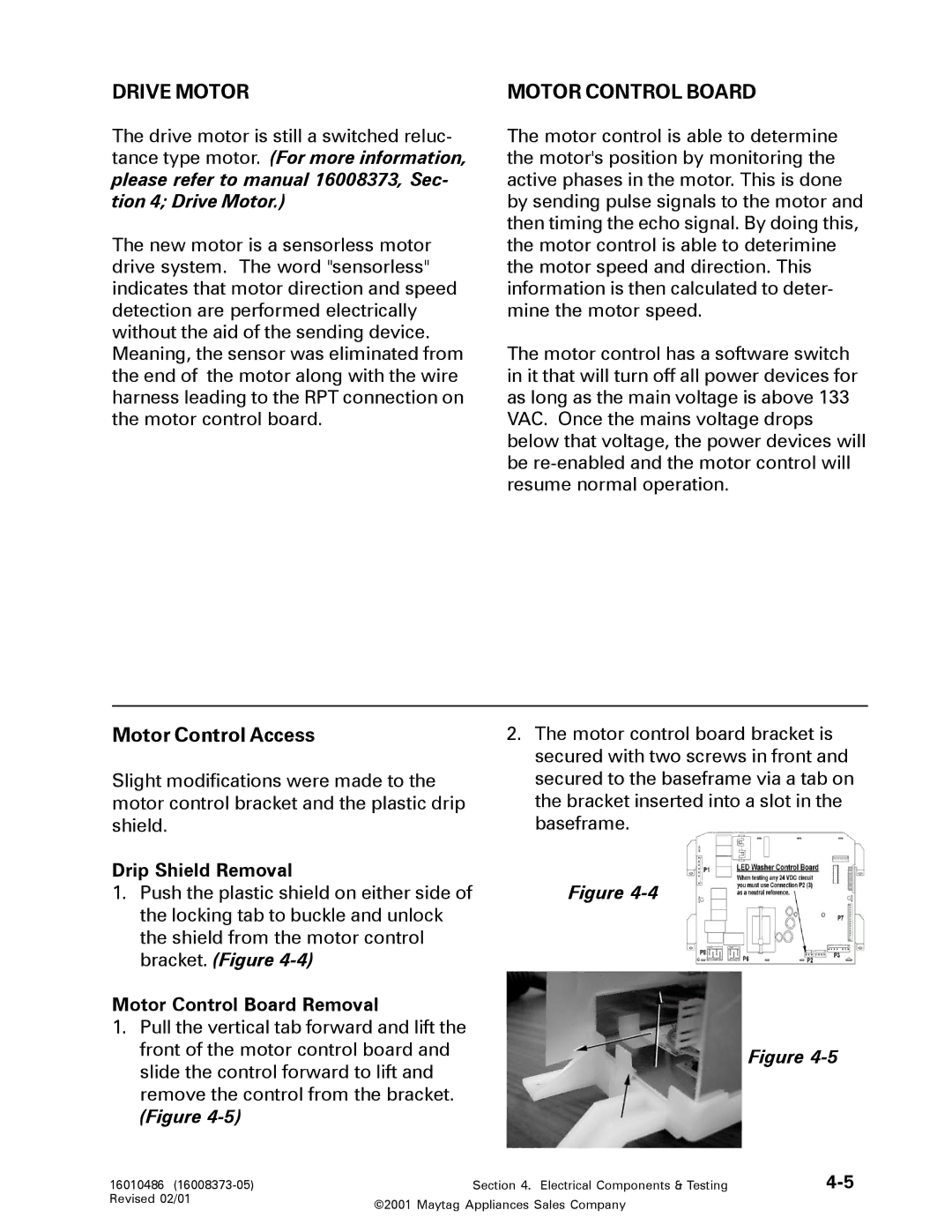

Motor Control Board Removal

1.Pull the vertical tab forward and lift the front of the motor control board and slide the control forward to lift and remove the control from the bracket.

(Figure

2.The motor control board bracket is secured with two screws in front and secured to the baseframe via a tab on the bracket inserted into a slot in the baseframe.

Figure

Figure

16010486

Revised 02/01 | ©2001 Maytag Appliances Sales Company |

|