Figure

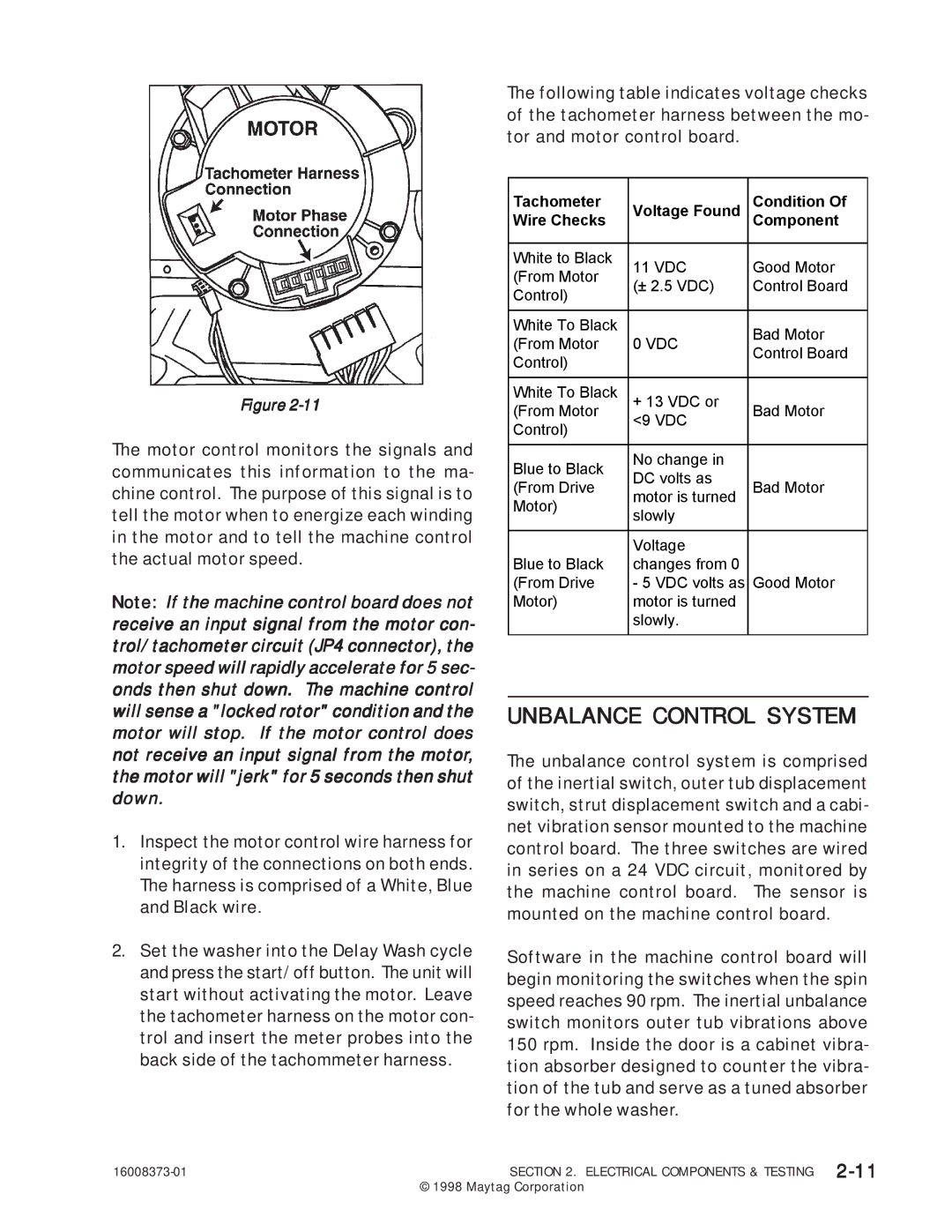

The motor control monitors the signals and communicates this information to the ma- chine control. The purpose of this signal is to tell the motor when to energize each winding in the motor and to tell the machine control the actual motor speed.

Note: If the machine control board does not receive an input signal from the motor con- trol/tachometer circuit (JP4 connector), the motor speed will rapidly accelerate for 5 sec- onds then shut down. The machine control will sense a "locked rotor" condition and the motor will stop. If the motor control does not receive an input signal from the motor, the motor will "jerk" for 5 seconds then shut down.

1.Inspect the motor control wire harness for integrity of the connections on both ends. The harness is comprised of a White, Blue and Black wire.

2.Set the washer into the Delay Wash cycle and press the start/off button. The unit will start without activating the motor. Leave the tachometer harness on the motor con- trol and insert the meter probes into the back side of the tachommeter harness.

The following table indicates voltage checks of the tachometer harness between the mo- tor and motor control board.

Tachometer | Voltage Found | Condition Of | |

Wire Checks | Component | ||

|

|

| |

White to Black | 11 VDC | Good Motor | |

(From Motor | |||

(± 2.5 VDC) | Control Board | ||

Control) | |||

|

| ||

|

|

| |

White To Black |

| Bad Motor | |

(From Motor | 0 VDC | ||

Control Board | |||

Control) |

| ||

|

| ||

|

|

| |

White To Black | + 13 VDC or | Bad Motor | |

(From Motor | <9 VDC | ||

Control) |

| ||

|

| ||

|

|

| |

Blue to Black | No change in |

| |

DC volts as |

| ||

(From Drive | Bad Motor | ||

motor is turned | |||

Motor) | slowly |

| |

|

| ||

|

|

| |

| Voltage |

| |

Blue to Black | changes from 0 |

| |

(From Drive | - 5 VDC volts as | Good Motor | |

Motor) | motor is turned |

| |

| slowly. |

| |

|

|

|

UNBALANCE CONTROL SYSTEM

The unbalance control system is comprised of the inertial switch, outer tub displacement switch, strut displacement switch and a cabi- net vibration sensor mounted to the machine control board. The three switches are wired in series on a 24 VDC circuit, monitored by the machine control board. The sensor is mounted on the machine control board.

Software in the machine control board will begin monitoring the switches when the spin speed reaches 90 rpm. The inertial unbalance switch monitors outer tub vibrations above 150 rpm. Inside the door is a cabinet vibra- tion absorber designed to counter the vibra- tion of the tub and serve as a tuned absorber for the whole washer.

SECTION 2. ELECTRICAL COMPONENTS & TESTING | |

| © 1998 Maytag Corporation |