SECTION 2 - INSTALLATION

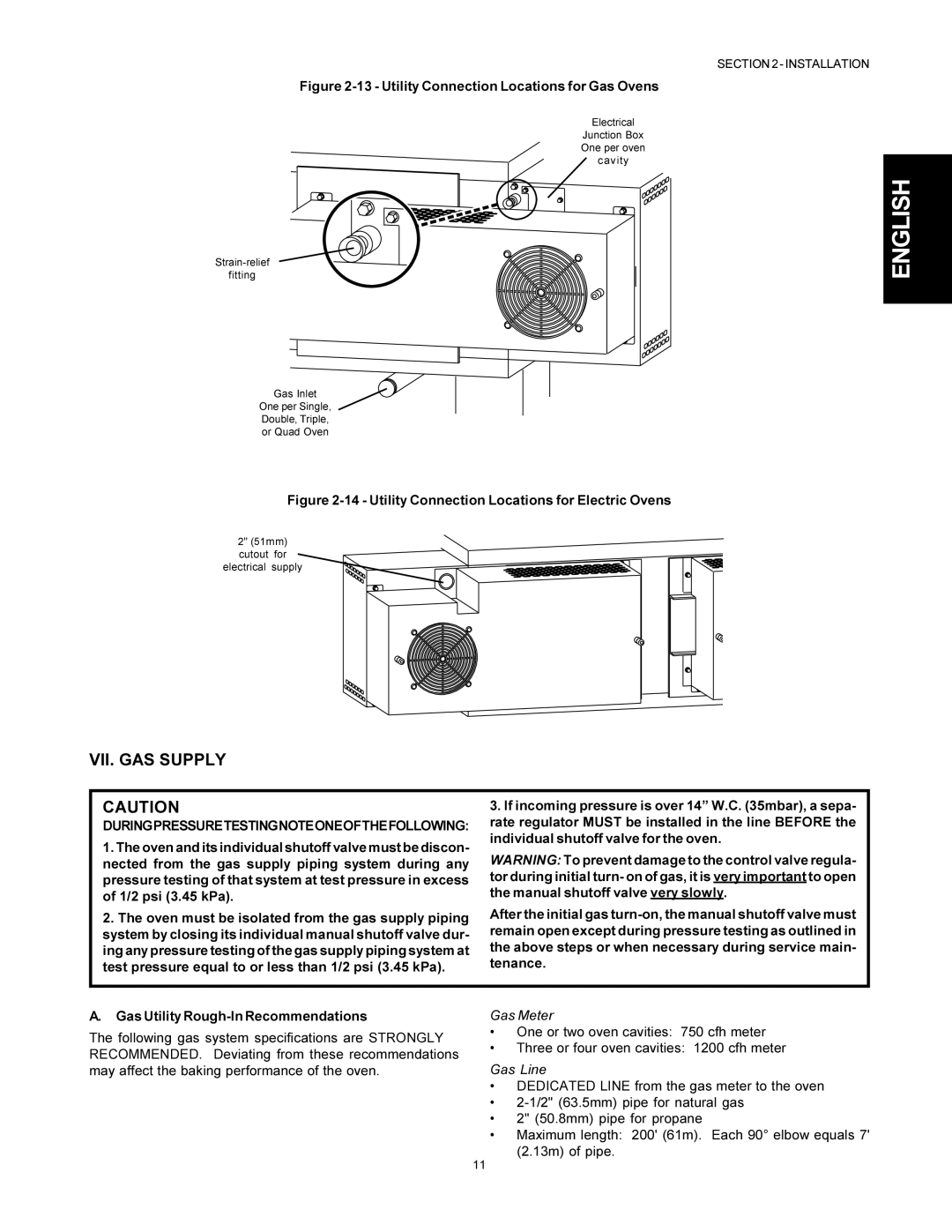

Figure 2-13 - Utility Connection Locations for Gas Ovens

Electrical

Junction Box One per oven cavity

fitting

Gas Inlet

One per Single, Double, Triple, or Quad Oven

ENGLISH

Figure 2-14 - Utility Connection Locations for Electric Ovens

2" (51mm) cutout for electrical supply

VII. GAS SUPPLY

CAUTION | 3. If incoming pressure is over 14” W.C. (35mbar), a sepa- | |

DURINGPRESSURETESTINGNOTEONEOFTHEFOLLOWING: | rate regulator MUST be installed in the line BEFORE the | |

1. The oven and its individual shutoff valve must be discon- | individual shutoff valve for the oven. | |

WARNING: To prevent damage to the control valve regula- | ||

nected from the gas supply piping system during any | ||

pressure testing of that system at test pressure in excess | tor during initial turn- on of gas, it is very important to open | |

of 1/2 psi (3.45 kPa). | the manual shutoff valve very slowly. | |

2. The oven must be isolated from the gas supply piping | After the initial gas | |

system by closing its individual manual shutoff valve dur- | remain open except during pressure testing as outlined in | |

ing any pressure testing of the gas supply piping system at | the above steps or when necessary during service main- | |

test pressure equal to or less than 1/2 psi (3.45 kPa). | tenance. | |

|

|

A.Gas Utility

The following gas system specifications are STRONGLY RECOMMENDED. Deviating from these recommendations may affect the baking performance of the oven.

Gas Meter

•One or two oven cavities: 750 cfh meter

•Three or four oven cavities: 1200 cfh meter

Gas Line

•DEDICATED LINE from the gas meter to the oven

•

•2" (50.8mm) pipe for propane

•Maximum length: 200' (61m). Each 90° elbow equals 7' (2.13m) of pipe.

11