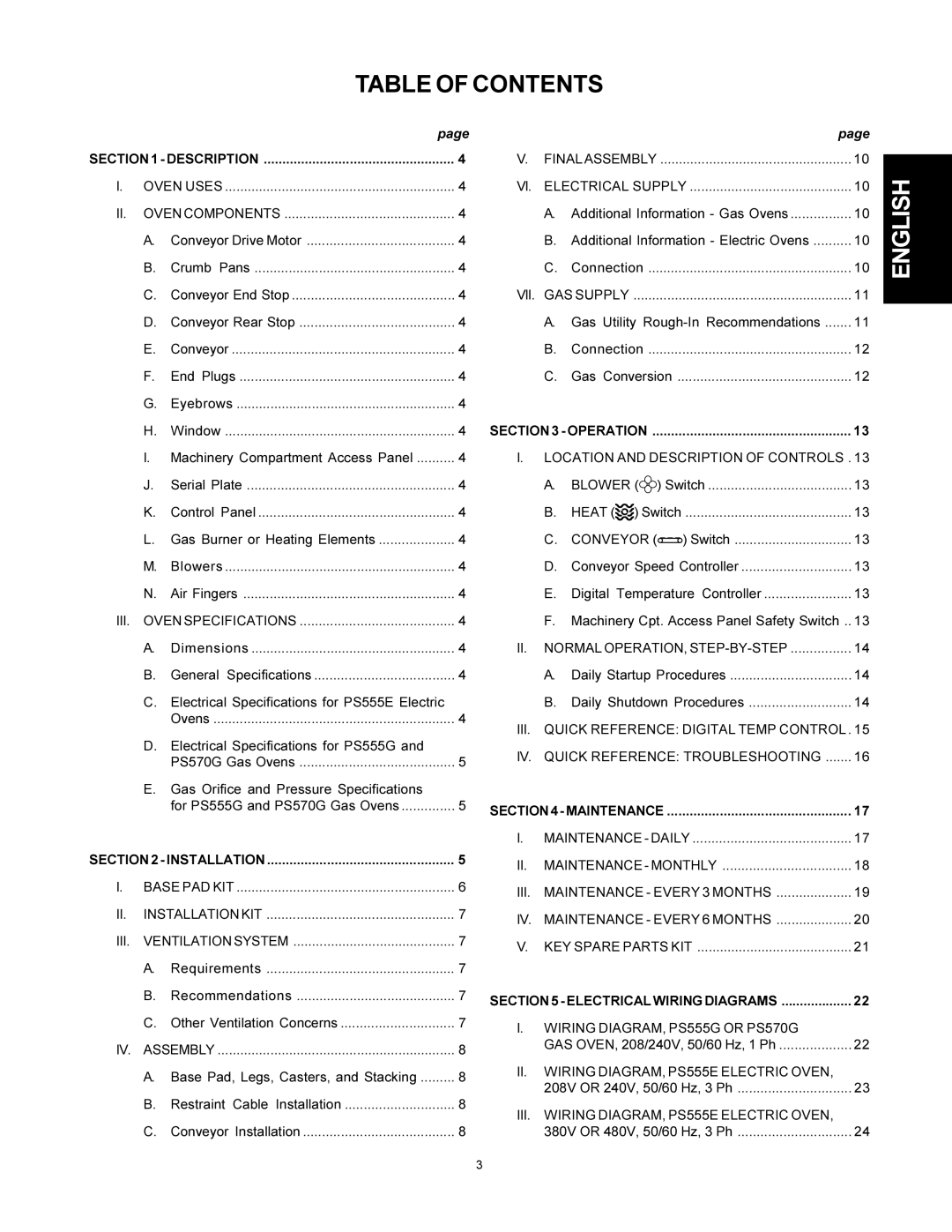

TABLE OF CONTENTS

|

| page |

|

|

|

|

|

|

|

|

| page | ||

SECTION 1 - DESCRIPTION | 4 | V. | FINAL ASSEMBLY | ................................................... |

|

|

|

|

| 10 | ||||

I. | OVEN USES | 4 | VI. | ELECTRICAL SUPPLY | 10 | |||||||||

II. | OVEN COMPONENTS | 4 |

| A. | Additional Information - Gas Ovens | 10 | ||||||||

| A. | Conveyor Drive Motor | 4 |

| B. | Additional Information - Electric Ovens | 10 | |||||||

| B. | Crumb Pans | 4 |

| C. | Connection |

|

|

|

|

|

| 10 | |

| C. | Conveyor End Stop | 4 | VII. GAS SUPPLY |

|

|

|

|

|

| 11 | |||

| D. | Conveyor Rear Stop | 4 |

| A. | Gas Utility | 11 | |||||||

| E. | Conveyor | 4 |

| B. | Connection |

|

|

|

|

|

| 12 | |

| F. | End Plugs | 4 |

| C. | Gas Conversion | 12 | |||||||

| G. | Eyebrows | 4 |

|

|

|

|

|

|

|

|

|

|

|

| H. | Window | 4 | SECTION 3 - OPERATION |

|

|

|

|

|

| 13 | |||

| I. | Machinery Compartment Access Panel | 4 | I. | LOCATION AND DESCRIPTION OF CONTROLS . 13 | |||||||||

| J. | Serial Plate | 4 |

| A. | BLOWER ( | ) Switch | 13 | ||||||

| K. | Control Panel | 4 |

| B. | HEAT ( ) Switch | 13 | |||||||

| L. | Gas Burner or Heating Elements | 4 |

| C. | CONVEYOR ( |

|

|

|

|

|

| ) Switch | 13 |

|

|

|

|

|

| |||||||||

| M. | Blowers | 4 |

| D. | Conveyor Speed Controller | 13 | |||||||

| N. | Air Fingers | 4 |

| E. | Digital Temperature Controller | 13 | |||||||

III. | OVEN SPECIFICATIONS | 4 |

| F. | Machinery Cpt. Access Panel Safety Switch .. | 13 | ||||||||

| A. | Dimensions | 4 | II. | NORMAL OPERATION, | 14 | ||||||||

| B. | General Specifications | 4 |

| A. | Daily Startup Procedures | 14 | |||||||

| C. | Electrical Specifications for PS555E Electric |

|

| B. | Daily Shutdown Procedures | 14 | |||||||

|

| Ovens | 4 | III. | QUICK REFERENCE: DIGITAL TEMP CONTROL . 15 | |||||||||

|

|

|

| |||||||||||

| D. | Electrical Specifications for PS555G and |

| IV. QUICK REFERENCE: TROUBLESHOOTING | 16 | |||||||||

|

| PS570G Gas Ovens | 5 | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

E.Gas Orifice and Pressure Specifications

|

| for PS555G and PS570G Gas Ovens | 5 | SECTION 4 - MAINTENANCE | 17 | |

|

|

|

| |||

|

|

|

| I. | MAINTENANCE - DAILY | 17 |

SECTION 2 - INSTALLATION | 5 | II. | MAINTENANCE - MONTHLY | 18 | ||

|

|

|

| |||

I. | BASE PAD KIT | 6 | III. | MAINTENANCE - EVERY 3 MONTHS | 19 | |

|

|

|

| |||

II. | INSTALLATION KIT | 7 | IV. MAINTENANCE - EVERY 6 MONTHS | 20 | ||

|

|

|

| |||

III. | VENTILATION SYSTEM | 7 | V. | KEY SPARE PARTS KIT | 21 | |

|

|

|

| |||

| A. | Requirements | 7 |

|

|

|

| B. | Recommendations | 7 | SECTION 5 - ELECTRICAL WIRING DIAGRAMS | 22 | |

|

|

|

| |||

| C. | Other Ventilation Concerns | 7 | I. | WIRING DIAGRAM, PS555G OR PS570G |

|

|

|

|

|

| ||

IV. | ASSEMBLY | 8 |

| GAS OVEN, 208/240V, 50/60 Hz, 1 Ph | 22 | |

|

|

| ||||

| A. | Base Pad, Legs, Casters, and Stacking | 8 | II. | WIRING DIAGRAM, PS555E ELECTRIC OVEN, |

|

|

| 208V OR 240V, 50/60 Hz, 3 Ph | 23 | |||

|

|

|

|

| ||

| B. | Restraint Cable Installation | 8 | III. | WIRING DIAGRAM, PS555E ELECTRIC OVEN, |

|

|

|

|

|

| ||

| C. | Conveyor Installation | 8 |

| 380V OR 480V, 50/60 Hz, 3 Ph | 24 |

ENGLISH

3