Table of Contents

Introduction

Software Security

Separate ADDRESS/DATA BUS

IN±SYSTEM Loading

Large Nonvolatile Memory

High Reliability Operation

Module Description ON±BOARD Memory Package

DS5000FP Soft Microprocessor Chip

Product Description

DS5000T Soft Microcontroller Module

DS2250T Soft Microcontroller Module

DS2251T 128K Soft Microcontroller Module

DS5002FP Secure Microprocessor Chip

DS2252T Secure Microcontroller Module

Chip Description Maximum Speed Part Number

Selection Guide

Module Description

Speed Clock Part Number

Secure Microcontroller Architecture

Secure Microcontroller Architectural Block Diagram Figure

Parallel I/O

Timed Access Logic

Program/Data RAM Interface

High±Reliability Circuitry

Resident Loader ROM

Watchdog Timer

Secure Microcontroller Memory Organization

Programmers Guide

Secure Microcontroller Memory MAP ±1

Internal Registers

Scratchpad Register MAP ±2

Program and Data Memory

PSW.4±3 R1±R0 Register Bank Select

Bank Starting Address R0

Important Application Note

DS5000 Series Memory Organization

DS5000 Series Memory MAP ±3

Memory map. The first is the EA pin. The second is

Overrides the condition of the EA pin as well

DS5000 Memory Map Control

DS5000 Series Mcon Register ±4 Bit Description

PA3

MCON.3

DS5001/DS5002 Memory Organization

RA32/8

MCON.2 ECE2

PA3 PA2 PA1 PA0 Partition BYTE±WIDE BUS Memory MAP

RG1 RG0 Range CE1 Access CE2 Access

Partitionable Memory MAP for DS5001/DS5002 Series ±5

Msel RG1 RG0 Program Data Program Access Data Access

CE1 CE3 CE4

CE1 CE2 CE3

DS5001/DS5002 Memory Mapped Peripherals

NON±PARTITIONABLE Memory MAP for DS5001, DS5002 Series ±6

DS5001/DS5002 Memory Map Control

Peripheral Enables in the Data Memory MAP ±7

PA3 PA2 PA1 PA0 RG1 PES

DS5001/DS5002 Series Mcon Register ±8

MCON.3 RG1

MCON.2 PES

RPCTL.5 Exbs

Loading and Reloading Program Memory

RPCTL.4

RPCTL.0 RG0

050396 23/173

Reloading Portions of a DS5000 Series Device ±10

Soft Reload of a DS5001/DS5002

Reloading a DS5001/DS5002 Series Device ±11

Special Function Registers

ECE2

DS5000 Series Special Function Register MAP ±12

CRC

DS5001/DS5002 Series Special Function Register MAP ±13

Label Pcon Register Address 087H

Power Control Register

PCON.2 EWT

PCON.3EPFW

PCON.1 Stop

PCON.0 IDL

Label Tcon Register Address 088H

Timer Control Register

Label Tmod Register Address 089H

Timer Mode Register

TCON.0 IT0

Gate

LabelSCON Register Address 098H

Serial Control Register

LabelIE Register Address 0A8H

Interrupt Enable Register

SCON.0

ET1

LabelIP Register Address 0B8H

Interrupt Priority Register

Label CRC Register Address 0C1H

DS5001 CRC Register

RNGE3±0

CRC.1 MDM

LabelMCON Register Address 0C6H

DS5000 Memory Control Register

PA3 PA2 PA1 PA0

RA32/8

DS5001 Mcon Register

Label Mcon Register Address 0C6H

MCON.0

Accessed by Movx instructions on the Byte±wide bus

LabelPSW Register Address 0D0H

Program Status Word Register

Label Rpctl Register Address 0D8H

DS5001/DS5002 RPC Control Register

RPCTL.7 RNR

RPCTL.3 IBI

Label RPS Register Address 0DAH

DS5001/DS5002 RPC Status Register

RPCTL.1 Rpcon

IA0

IBF

RPS.1

RPS.0

OBF

Addressing Modes

Instruction SET

ADD A, R4

Setb 00H

Addressing

±20 Branch to the location PC+2 ±

Acall 100H Call to the subroutine at

Address

Instructions That Affect Flag Settings

Program Status Flags

Flags Instruction OV AC

Recommended SRAMs for USE with Soft Microcontrollers ±1

Memory Interconnect

Data Reten Part Tion Current RAM Size Vendor

25C 40C 70C

Memory Interconnect of the DS5000FP ±1

DS5000 Series Module Block Diagram ±2

Memory Interconnect of the Partitionable DS5001/DS5002 ±3

Óóóóóóóóó Ó

Óóóóóóóó 52 14Ó GND

Memory Interconnect Using the 128K Sram ±5

DS2251T±128 Block Diagram ±6

Ôôôôôô

DS2252T±32 Block Diagram ±7

LITHIUM/BATTERY Backup

Battery Backed Circuits

Data Retention

Battery Attach Procedure

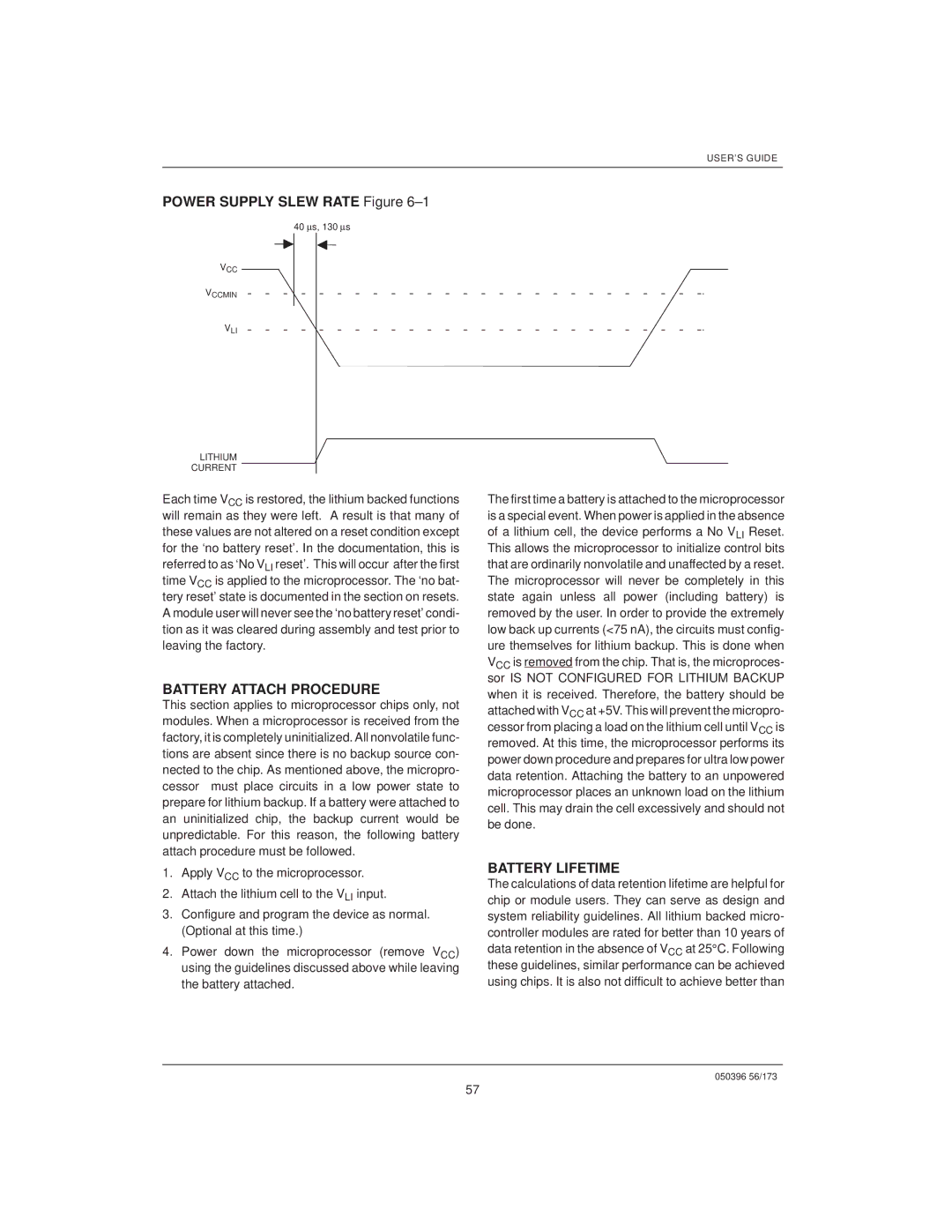

Power Supply Slew Rate ±1

Battery Lifetime

Battery attached

54 * 10±3

180 * 10±3

2400 + 75 * 10±9 * 24 21.68 * 10±3

Freshness Seal

Lithium Battery Usage

Idle Mode

Power Management

CONTROL/STATUS Bits for Power Control ±1 Bit Description

ªPower On Resetº

Mode Program ALE Psen Memory

Stop Mode

PIN States in IDLE/STOP Modes ±1

PCON.3 Epfw

Voltage Monitoring Circuitry

Secure Microcontroller Power Cycling Timing ±2

Total Power Failure

Power Fail Interrupt

Partial Power Failures

Vpfw threshold is above the specified minimum

Reset Vector

Secure Microcontroller Power Management ±3

Timed Access

Timed Access ±1

Software Control

BIT Name Micro Version Location Description

Timed Access Protected Control Bits ±1

050396 66/173

Watchdog Timer ±2

0C7H, #055H 2nd TA Value

IP.7

CRC Memory Verification

Watchdog Timer Control Bits

Range 3±0

DS5001 CRC Register Address 0C1h

CRC.1

CRC.0

This routine tests the CRC±16 circuit in the DS5001FP

CRC Code Example ±3

Firmware Security

Feature

Security Overview

DS5001 DS5000 DS5002

Security Lock

RAM Memory

Encrypted Memory

DS5002 Software Encryption Block Diagram ±2

DS5000 Software Encryption Block Diagram ±1

050396 74/173

Encryption Algorithm

Encryption Key

Encryption Key Selection and Loading

Dummy BUS Access Timing ±3

Dummy Bus Access

Self±Destruct Input

On±chip Vector RAM

Microprobe/Die Top Coating

Random Number Generator

Security Summary by Part

DS5000FP / DS5000T / DS2250T

DS5001FP / DS2251T

Application Advanced Security Techniques

Change Code

External Circuits

Tamper Protection

Reset Conditions

Reset Sources

Reset Status Bits ±1

Special Function Register Reset States ±1

Reset Condition Reset Type

Register

Power On Reset

Power on Reset Timing ±2

Chanical and some time is required to get the mass

No±VLI Power On Reset

External Reset

Watchdog Timer Reset

Application Reset Routine Example

Memory Interrupts TIMERS/SERIAL Protection

Memory Map

Timed ± DS5000 only

Interrupts

Tively. Shown here is an example of Timer and Serial

Timers

Microprocessor disables timer activity excluding

Protection

Interrupts

Interrupt Source Enable BIT Location

Interrupt Sources

Interrupt Source Vector Address Flag Flag Location

Power±fail Warning Interrupt

Timer Interrupts

Machine cycle when the interrupts are enabled. INT0 is

External Interrupts

Interrupt Request Sources ±1

Simulated Interrupts

Interrupt Enable Control Bits ±2 Bit Description

ET0

EX0

Interrupt Priority Control Bits ±3 Bit Description

Interrupt Priorities

Priority Flag Interrupt Source

IP.4

Interrupt Acknowledge

Interrupt Acknowledge Sequence ±4

Flag Vector Address Interrupt Source

050396 94/173

Port 0 Functional Circuitry ±1

Parallel I/O Overview

PIN Name

Function

Port 2 Functional Circuitry

Port 1 Functional Circuitry

Output Functions

Port 3 Functional Circuitry

Input Function

Parallel Port Output Buffers Ports 1, 2, and 3 ±2

Reprogrammable Peripheral Controller RPC

READ±MODIFY±WRITE Instructions

Mnemonic Description

Port 0 D0±7

USE of the RPC Mode ±4

USE of the RPC Mode ±3

Command

RPC Interrupts

ST7 ST6 ST5 ST4 IAO IBF OBF

RPC Status Register ± Status Address 0DAH ±5

DMA Operation

RPC Protocol

Dbbout

103

RPC Control Register ± Rpctl Address 0D8H ±6

Port 2 becomes the control signals as shown in ±3

RNR Exbs IBI DMA Rpcon RG0

Rpcon bit is set

Programmable Timers Functional Description

TMOD.6 Timer TMOD.2 Timer

Tmod Register Control BIT Summary ±1 Bit Description

Tcon Register CONTROL/STATUS Bits ±2

TMOD.5, TMOD.4

TMOD.1, TMOD.0

Mode

TIMER/COUNTER Mode 0 and 1 Operation ±3

Scribed for TR0, TF0, and INT0

107

108

TIMER/COUNTER Mode 2 Operation ±4

109

Timer 0 Mode 3 Operation ±5

Serial I/O Function Description

Mode SYNC/ASYNC Baud Clock

Serial Port Operating Modes ±1

START/STOP

Mode Sync Bits CLK Async Timer 1 Overflow

Mode Function Word Length Period

Serial Port Control Register ±1 Bit Description

ªXmit Bit 8º

SCON.1

SCON.2 RB8

SCON.0

Baud Rate Generation

Synchronous Operation Mode

Timer 1 Baud Rate Generation ±2

Smod Timer TH1

Baud Rate BPS

114

115

Mode 0 Block Diagram and Timing ±2

116

Asynchronous Operation

Mode 2

Smod BRG Clock

117

118

Serial Port Mode 1 Block Diagram ±3

119

MODE2 and 3 Block Diagram ±4

Mode Function Word Length Baud Clock

Application Serial Port Initialization

Serial I/O Operating Modes

TB8 RB8

SM0 SM1 SM2 REN

ET1 EX1 ET0 EX0

PT1 PX1 PT0 PX0

Smod POR PFW WTR Epfw EWT Stop IDL

TF1 TR1 TF0 TR0

IE1 IT1 IE0

123

Crystal Connection ±1

CPU Timing Oscillator

Clock Source Input ±2

XTAL1

125

Instruction Timing

BYTE±WIDE RAM Instruction Execution Timing ±3

Expanded Program Memory Timing

126

127

Expanded Program Memory Fetch ±4

Expanded Data Memory Read ±5

Expanded Data Memory Write ±6

128

Expanded Data Memory Timing

Complete RD cycle, including activation of ALE and RD

129

Program Loading Introduction

Invoking the Bootstrap Loader

DS5000FP DS5001/2FP

130

DS5001/DS5002 Series

DS5000 Series

Exiting the Loader

131

MODEM=1 PROG=0

132

Serial Program Load Mode

Serial Load Configuration ±2

133

Baud Rate

AUTO±BAUD Rate Detection

Crystal Freq MHz 300 1200 2400

57600

Command Line Interface

Bootstrap Loader Initialization

Command Line Syntax

Command Function Version

Begin±address end±address

Command Summaries

→ 000AH AB → 00ABH

ABC → 0ABCH Abcd → 0ABCDH Abcde → 0BCDEH

Byte±1 byte±2 byte±3 byte±4 byte±5

Byte begin±address end±address

Byte

P0 value P1 value P2 value P3 value

CRC/MCON/MSL/RPCTL byte

Xon/Xoff

Mcon

MSL

Eextarg

Error Messages Eargreq

Eillcmd

Eillopt

140

Intel HEX File Format

Parallel Program Load Operation

Parallel Program Load Configuration ±3

Parallel Program Load Cycles ±4

141

Mode RST Psen Prog

Parallel Program Load Mode

8751±COMPATIBLE Program Load Cycles ±3

P2.7 P2.6 P2.5

Parallel Programming Concerns

RPC Program Mode Operation

Pulses specified, each with a low time of 90 to

143

REAL±TIME Clock

DS5000T/DS2250T Functional Block Diagram ±1

DS1215 Phantom Time Chip

144

145

146

Pattern Comparison Register Description ±2

147

DS1215 Register Entry Flowchart ±3

Registers

DS1215 Time Registers Description ±4

Special Bits

148

149

Time Register Examples ±5

150

DS1283 Watchdog Timekeeper Chip

DS2251T/DS2252T RTC Block Diagram ±6

Memory MAP

151

152

DS1283 REAL±TIME Clock Memory MAP ±7

DS1283 REAL±TIME Clock Command Register ±8

Alarm Condition

Alarm Maskbit Operation ±9

DS1283 RTC Interrupts

Mask

155

Application Using the DS5000T RTC DS1215 Example

156

Wbyte

157

RET

158

159

Application Using the DS2251T RTC DS1283 Example

160

161

162

163

Unexplained Device Resets

Troubleshooting

RAM Loses Data When Powered Down

Time Microcontroller Reads the Wrong Time

Unable to Invoke Stop Mode

Serial Port does not Work

Program will not Execute

Data is Lost or Corrupted

High Current Drain in Stop Mode

INT0 is Stuck LOW on DS2252T

DS5000TK KIT does not Respond to KIT5K Software

DOS

Mnemonic Instruction Code HEX Byte Cycle Explanation

Instruction SET Details

CLR a CPL a

DA a

RLC a

RL a

RR a

RRC a

Mnemonic Instruction Code HEX Byte

Setb bit Bit =

CLR bit Bit =

CPL bit Bit = bit

ANL C, bit = C and bit

RET

Reti

Dptr

NOP