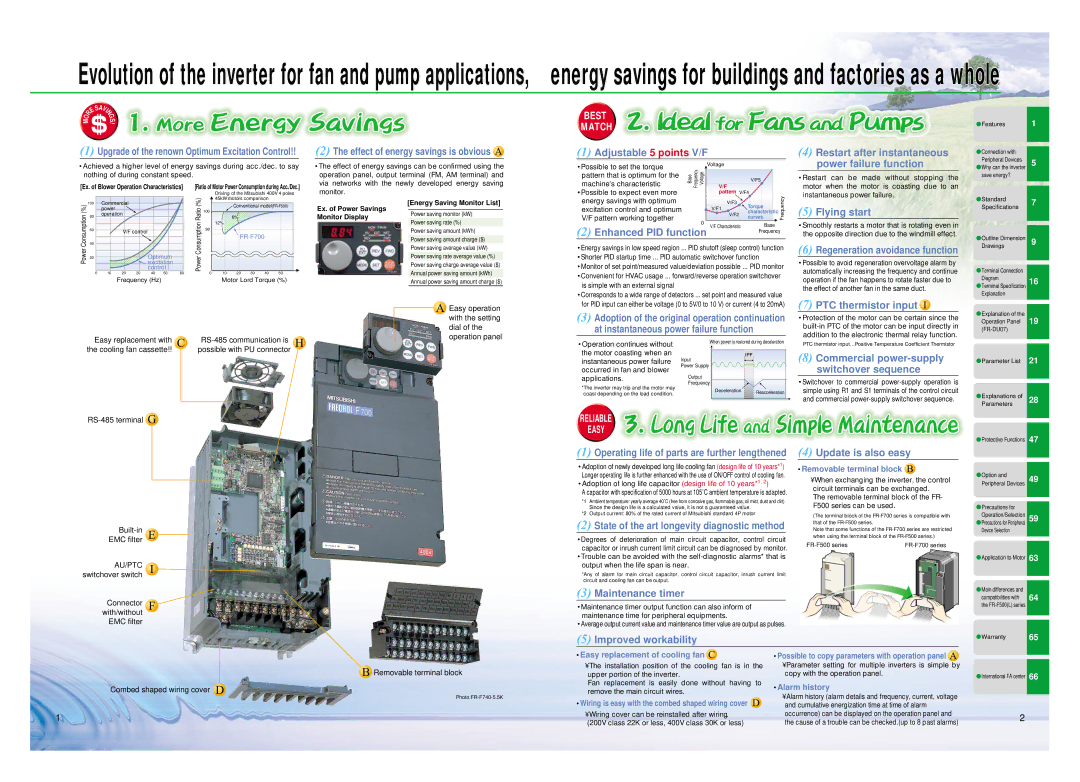

Evolution of the inverter for fan and pump applications,

energy savings for buildings and factories as a whole

|

| SA | ||||||||||||||||

| E |

| VI | |||||||||||||||

|

| N | ||||||||||||||||

O | R |

| G | |||||||||||||||

M |

| S | ||||||||||||||||

! |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BEST |

| 1 |

MATCH | Features |

(1)Upgrade of the renown Optimum Excitation Control!!

•Achieved a higher level of energy savings during acc./dec. to say nothing of during constant speed.

[Ex. of Blower Operation Characteristics] | [Ratio of Motor Power Consumption during Acc./Dec.] |

Driving of the Mitsubishi 400V 4 poles |

45kW motors comparison |

(2)The effect of energy savings is obvious A

•The effect of energy savings can be confirmed using the operation panel, output terminal (FM, AM terminal) and via networks with the newly developed energy saving monitor.

(1) Adjustable 5 points V/F | |||

•Possible to set the torque |

| Voltage | |

Base Frequency Voltage |

| ||

pattern that is optimum for the | V/F5 | ||

machine's characteristic | |||

V/F | |||

•Possible to expect even more |

| pattern V/F4 | |

(4)Restart after instantaneous power failure function

•Restart can be made without stopping the motor when the motor is coasting due to an instantaneous power failure.

Connection with |

|

Peripheral Devices | 5 |

Why can the inverter | |

save energy? |

|

100 | Commercial | Consumption Ratio(%) | Conventional | |

| power | |||

| 100 | |||

| operation | |||

80 | 6% | |||

| ||||

|

| 12% | ||

60 | V/F control | 90 | ||

Consumption(%) | ||||

| ||||

|

|

Ex. of Power Savings Monitor Display

[Energy Saving Monitor List]

Power saving monitor (kW)

Power saving rate (%)

Power saving amount (kWh) Power saving amount charge ($)

energy savings with optimum |

|

| V/F3 | Torque |

|

|

| Frequency |

| |

excitation control and optimum |

|

| V/F1 |

|

|

|

| |||

|

| characteristic |

|

|

| |||||

|

| V/F2 |

|

|

| |||||

V/F pattern working together |

|

| curves |

|

|

|

| |||

|

|

|

|

|

|

| ||||

0 |

| V/F Characteristic |

|

| Base |

|

| |||

(2) Enhanced PID function |

|

|

|

| ||||||

|

|

| Frequency |

| ||||||

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(5)Flying start

•Smoothly restarts a motor that is rotating even in the opposite direction due to the windmill effect.

Standard 7 Specifications

| 40 |

|

|

|

|

|

|

|

|

|

|

|

|

Power | 20 |

|

|

| Optimum |

| Power |

|

|

|

|

| |

|

|

|

| excitation |

|

|

|

|

|

| |||

0 | 10 | 20 | 30 | control | 60 | 10 | 20 | 30 | 40 | 50 | |||

| 40 | 50 | 0 | ||||||||||

Frequency (Hz) | Motor Lord Torque (%) |

Power saving average value (kW)

Power saving rate average value (%)

Power saving charge average value ($) Annual power saving amount (kWh)

Annual power saving amount charge ($)

•Energy savings in low speed region ... PID shutoff (sleep control) function •Shorter PID startup time ... PID automatic switchover function •Monitor of set point/measured value/deviation possible ... PID monitor •Convenient for HVAC usage ... forward/reverse operation switchover

is simple with an external signal

(6)Regeneration avoidance function

•Possible to avoid regeneration overvoltage alarm by automatically increasing the frequency and continue operation if the fan happens to rotate faster due to the effect of another fan in the same duct.

Drawings |

|

Terminal Connection |

|

Diagram | 16 |

Terminal Specification |

Easy replacement with |

A Easy operation with the setting dial of the operation panel

•Corresponds to a wide range of detectors ... set point and measured value for PID input can either be voltage (0 to 5V/0 to 10 V) or current (4 to 20mA)

(3)Adoption of the original operation continuation at instantaneous power failure function

(7)PTC thermistor input I

•Protection of the motor can be certain since the

Explanation |

Explanation of the |

Operation Panel 19 |

the cooling fan cassette!! C | possible with PU connector H |

EMC filter E

AU/PTC I

switchover switch

with/withoutConnector F EMC filter

•Operation continues without | When power is restored during deceleration | ||

|

| ||

the motor coasting when an | Input | IPF | |

instantaneous power failure |

| ||

Power Supply |

| ||

occurred in fan and blower |

| ||

|

| ||

applications. | Output |

| |

*The inverter may trip and the motor may | Frequency |

| |

Deceleration | Reacceleration | ||

coast depending on the load condition. | |||

| |||

RELIABLE

RELIABLE

EASY

(1)Operating life of parts are further lengthened

•Adoption of newly developed long life cooling fan (design life of 10 years*1) Longer operating life is further enhanced with the use of ON/OFF control of cooling fan. •Adoption of long life capacitor (design life of 10 years*1, 2)

A capacitor with specification of 5000 hours at 105˚C ambient temperature is adapted.

*1 Ambient temperature: yearly average 40˚C (free from corrosive gas, flammable gas, oil mist, dust and dirt) Since the design life is a calculated value, it is not a guaranteed value.

*2 Output current: 80% of the rated current of Mitsubishi standard 4P motor

(2)State of the art longevity diagnostic method

•Degrees of deterioration of main circuit capacitor, control circuit capacitor or inrush current limit circuit can be diagnosed by monitor.

•Trouble can be avoided with the

*Any of alarm for main circuit capacitor, control circuit capacitor, inrush current limit circuit and cooling fan can be output.

(3)Maintenance timer

•Maintenance timer output function can also inform of maintenance time for peripheral equipments.

•Average output current value and maintenance timer value are output as pulses.

PTC thermistor input…Positive Temperature Coefficient Thermistor

(8)Commercial power-supply switchover sequence

•Switchover to commercial

(4)Update is also easy

•Removable terminal block B

¥When exchanging the inverter, the control circuit terminals can be exchanged.

The removable terminal block of the FR- F500 series can be used.

(The terminal block of the

Note that some functions of the

Parameter List | 21 |

Explanations of | 28 |

Parameters |

|

Protective Functions | 47 |

Option and | 49 |

Peripheral Devices | |

Precautions for |

|

Operation/Selection | 59 |

Precautions for Peripheral |

|

Device Selection |

|

Application to Motor | 63 |

Main differences and | 64 |

compatibilities with | |

the |

|

Combed shaped wiring cover D

1

BRemovable terminal block

(5) Improved workability

•Easy replacement of cooling fan C |

| •Possible to copy parameters with operation panel A | |

¥ The installation position of the cooling fan is in the | ¥ Parameter setting for multiple inverters is simple by | ||

upper portion of the inverter. |

| copy with the operation panel. | |

Fan replacement is easily done without having | to | •Alarm history | |

remove the main circuit wires. |

| ||

| ¥ Alarm history (alarm details and frequency, current, voltage | ||

•Wiring is easy with the combed shaped wiring cover | D | ||

and cumulative energization time at time of alarm | |||

¥ Wiring cover can be reinstalled after wiring. |

| occurrence) can be displayed on the operation panel and | |

(200V class 22K or less, 400V class 30K or less) |

| the cause of a trouble can be checked.(up to 8 past alarms) | |

Warranty | 65 |

|

|

|

|

International FA center | 66 |

|

|

2