Full of attractive features!

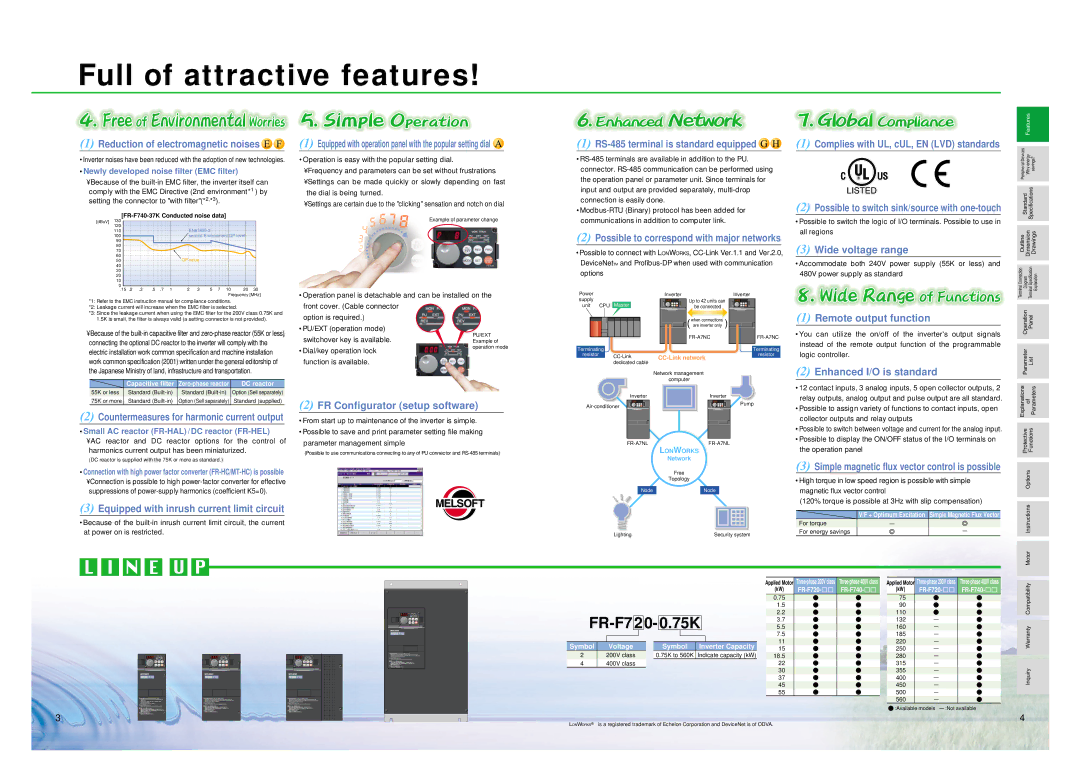

(1) Reduction of electromagnetic noises E F | (1) Equipped with operation panel with the popular setting dial A | (1) | (1) Complies with UL, cUL, EN (LVD) standards | |||||||||||

•Inverter noises have been reduced with the adoption of new technologies. | •Operation is easy with the popular setting dial. |

| ||||||||||||

•Newly developed noise filter (EMC filter) | ¥ Frequency and parameters can be set without frustrations. | connector. |

| |||||||||||

¥ Because of the | ¥ Settings can be made quickly or slowly depending on fast | the operation panel or parameter unit. Since terminals for |

| |||||||||||

input and output are provided separately, |

| |||||||||||||

comply with the EMC Directive (2nd environment*1 ) by | the dial is being turned. |

|

| |||||||||||

setting the connector to "with filter"(*2,*3). |

| ¥ Settings are certain due to the "clicking" sensation and notch on dial. | connection is easily done. |

| (2) Possible to switch sink/source with | |||||||||

|

|

|

|

|

|

| ||||||||

|

|

| ||||||||||||

|

| Example of parameter change | communications in addition to computer link. | •Possible to switch the logic of I/O terminals. Possible to use in | ||||||||||

[dBuV] 130 |

|

|

|

|

|

|

| |||||||

120 |

|

|

|

|

|

|

|

|

|

|

|

|

| all regions |

110 |

|

|

|

|

| (2) Possible to correspond with major networks | ||||||||

100 |

|

| second Environment QP level |

|

| |||||||||

|

|

|

|

| ||||||||||

90 |

|

|

|

|

|

|

|

| (3) Wide voltage range | |||||

80 |

|

|

|

|

|

|

|

| •Possible to connect with LONWORKS, | |||||

60 |

|

|

|

|

|

|

|

| ||||||

70 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

| QP value |

|

|

|

| DeviceNetTM and | •Accommodate both 240V power supply (55K or less) and | |||||

40 |

|

|

|

|

|

|

|

| ||||||

30 |

|

|

|

|

|

|

|

| options |

|

|

| 480V power supply as standard | |

20 |

|

|

|

|

|

|

|

|

|

|

| |||

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 | .2 .3 | .5 .7 1 | 2 | 3 | 5 7 10 | 20 30 |

|

|

|

|

|

|

|

|

.15 | •Operation panel is detachable and can be installed on the | Power |

|

| Inverter | Inverter |

| |||||||

|

|

|

|

| Frequency [MHz] |

|

|

| ||||||

*1: Refer to the EMC instruction manual for compliance conditions. |

| front cover. (Cable connector |

| supply |

| Master | Up to 42 units can |

| ||||||

*2: Leakage current will increase when the EMC filter is selected. |

| unit | CPU | be connected |

|

| ||||||||

*3: Since the leakage current when using the EMC filter for the 200V class 0.75K and | option is required.) |

|

|

|

|

|

| (1) Remote output function | ||||||

1.5K is small, the filter is always valid (a setting connector is not provided). |

|

|

|

| when connections | ) | ||||||||

¥ Because of the | •PU/EXT (operation mode) |

|

|

|

| ( are inverter only |

| |||||||

PU/EXT |

|

|

|

|

| •You can utilize the on/off of the inverter's output signals | ||||||||

switchover key is available. |

|

|

| |||||||||||

connecting the optional DC reactor to the inverter will comply with the | Example of |

|

|

| instead of the remote output function of the programmable | |||||||||

|

|

|

|

| ||||||||||

•Dial/key operation lock | operation mode | Terminating |

|

| Terminating | |||||||||

electric installation work common specification and machine installation |

|

|

| |||||||||||

|

|

| logic controller. | |||||||||||

| resistor |

| resistor | |||||||||||

work common specification (2001) written under the general editorship of | function is available. |

|

| |||||||||||

|

|

| dedicated cable |

|

| |||||||||

|

|

|

|

| (2) Enhanced I/O is standard | |||||||||

the Japanese Ministry of land, infrastructure and transportation. |

|

|

|

|

| Network management |

| |||||||

| Capacitive filter | DC reactor |

|

|

|

|

| computer |

|

| ||||

|

|

|

|

|

|

|

| •12 contact inputs, 3 analog inputs, 5 open collector outputs, 2 | ||||||

55K or less | Standard | Standard | Option (Sell separately) |

|

|

|

|

|

|

| ||||

|

|

|

| Inverter | Inverter | relay outputs, analog output and pulse output are all standard. | ||||||||

75K or more | Standard | Option (Sell separately) | Standard (supplied) | (2) FR Configurator (setup software) |

|

| ||||||||

|

|

|

| Pump | ||||||||||

| •Possible to assign variety of functions to contact inputs, open | |||||||||||||

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| |||

(2) Countermeasures for harmonic current output | •From start up to maintenance of the inverter is simple. |

|

|

|

|

| collector outputs and relay outputs | |||||||

•Small AC reactor | •Possible to save and print parameter setting file making |

|

|

|

|

| •Possible to switch between voltage and current for the analog input. | |||||||

¥ AC reactor and DC reactor options for the control of | parameter management simple |

|

|

| •Possible to display the ON/OFF status of the I/O terminals on | |||||||||

harmonics current output has been miniaturized. | (Possible to use communications connecting to any of PU connector and |

|

|

| LONWORKS |

| the operation panel | |||||||

(DC reactor is supplied with the 75K or more as standard.) |

|

|

|

|

|

| Network |

| (3) Simple magnetic flux vector control is possible | |||||

•Connection with high power factor converter |

|

|

|

|

| Free |

| |||||||

|

|

|

|

|

| •High torque in low speed region is possible with simple | ||||||||

¥ Connection is possible to high |

|

|

|

|

| Topology |

| |||||||

|

|

|

|

|

|

| ||||||||

suppressions of |

|

|

|

| Node | Node |

| magnetic flux vector control | ||||||

(3) Equipped with inrush current limit circuit |

|

|

|

|

|

|

| (120% torque is possible at 3Hz with slip compensation) | ||||||

|

|

|

|

|

|

|

| |||||||

V/F + Optimum Excitation Simple Magnetic Flux Vector

•Because of the |

|

|

|

|

|

|

|

| For torque | |||||||||||

at power on is restricted. |

|

|

|

|

|

|

|

| For energy savings | |||||||||||

|

|

|

|

|

|

|

| |||||||||||||

Lighting | Security system | |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Applied Motor | Applied Motor | ||||

|

|

|

| (kW) | (kW) | ||||

|

|

|

| 0.75 |

|

| 75 |

|

|

|

|

|

| 1.5 |

|

| 90 |

|

|

| 2.2 |

|

| 110 |

|

| |||

5.5 |

|

| 160 |

|

| ||||

|

|

|

| 3.7 |

|

| 132 |

|

|

|

|

|

| 7.5 |

|

| 185 |

|

|

Symbol | Voltage | Symbol | Inverter Capacity | 11 |

|

| 220 |

|

|

15 |

|

| 250 |

|

| ||||

2 | 200V class | 0.75K to 560K | Indicate capacity (kW) | 18.5 |

|

| 280 |

|

|

4 | 400V class |

|

| 22 |

|

| 315 |

|

|

|

|

|

| 30 |

|

| 355 |

|

|

|

|

|

| 37 |

|

| 400 |

|

|

|

|

|

| 45 |

|

| 450 |

|

|

|

|

|

| 55 |

|

| 500 |

|

|

|

|

|

|

|

|

| 560 |

|

|

|

|

|

|

|

|

| :Available models :Not available | ||

3

|

| Features |

|

| |

|

|

| |||

|

|

| |||

Peripheral Devices | Why energy | savings? | |||

|

|

|

|

|

|

| Standard | Specifications |

| ||

|

|

|

|

|

|

Outline | Dimension | Drawings | |||

|

|

|

|

|

|

|

|

|

|

|

|

Terminal Connection | Diagram | Terminal Specification | Explanation | ||

|

|

|

|

|

|

| Operation | Panel |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| Parameter | List |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

Explanations | of | Parameters | |||

|

|

|

|

|

|

| Protective | Functions |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Options |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Instructions |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Motor |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Compatibility |

|

| |

|

|

|

|

|

|

|

| Warranty |

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Inquiry |

|

| |

|

|

|

|

|

|

4

LONWORKS® is a registered trademark of Echelon Corporation and DeviceNet is of ODVA.