7

|

|

| Control keypad | 57(86) |

STOP | READY |

| STOP READY | STOP |

I /Oterm |

|

| I/ Oterm | I/ Oterm |

Keypad control |

| Control Place | Control Place | |

" | P3 |

| I/O Remote | I/O Remote |

P1 |

| |||

STOP READY |

| STOP READY |

| |

I/ Oterm |

|

| K eypad |

|

Control Place | enter | Control Place |

| |

Keypad |

|

| Keypad |

|

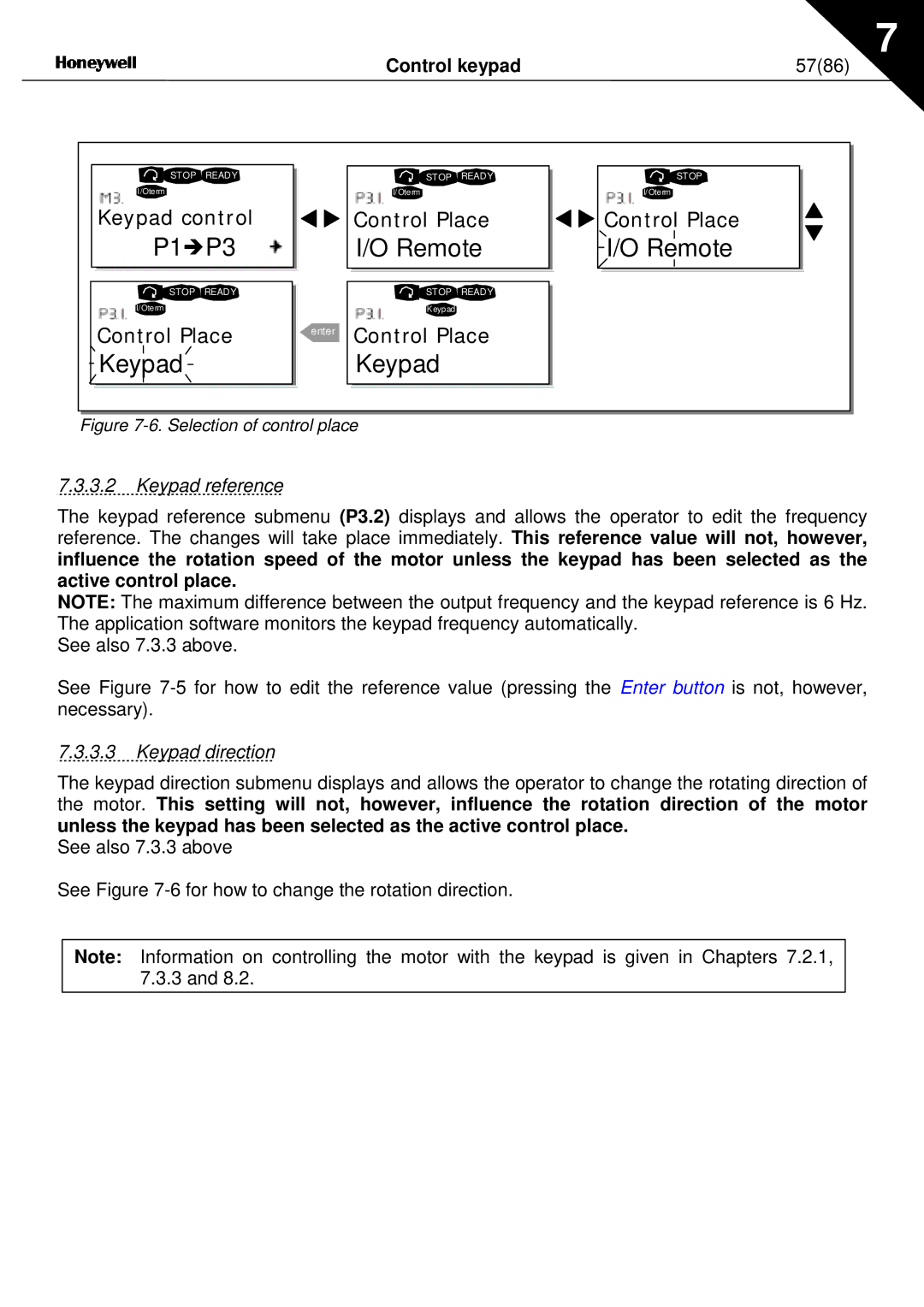

Figure 7-6. Selection of control place

7.3.3.2Keypad reference

The keypad reference submenu (P3.2) displays and allows the operator to edit the frequency reference. The changes will take place immediately. This reference value will not, however, influence the rotation speed of the motor unless the keypad has been selected as the active control place.

NOTE: The maximum difference between the output frequency and the keypad reference is 6 Hz. The application software monitors the keypad frequency automatically.

See also 7.3.3 above.

See Figure

7.3.3.3Keypad direction

The keypad direction submenu displays and allows the operator to change the rotating direction of the motor. This setting will not, however, influence the rotation direction of the motor unless the keypad has been selected as the active control place.

See also 7.3.3 above

See Figure

Note: Information on controlling the motor with the keypad is given in Chapters 7.2.1, 7.3.3 and 8.2.