Cabling and connections | 39(86) |

6.1.3Cable installation and the UL standards

To meet the UL (Underwriters Laboratories) regulations, a

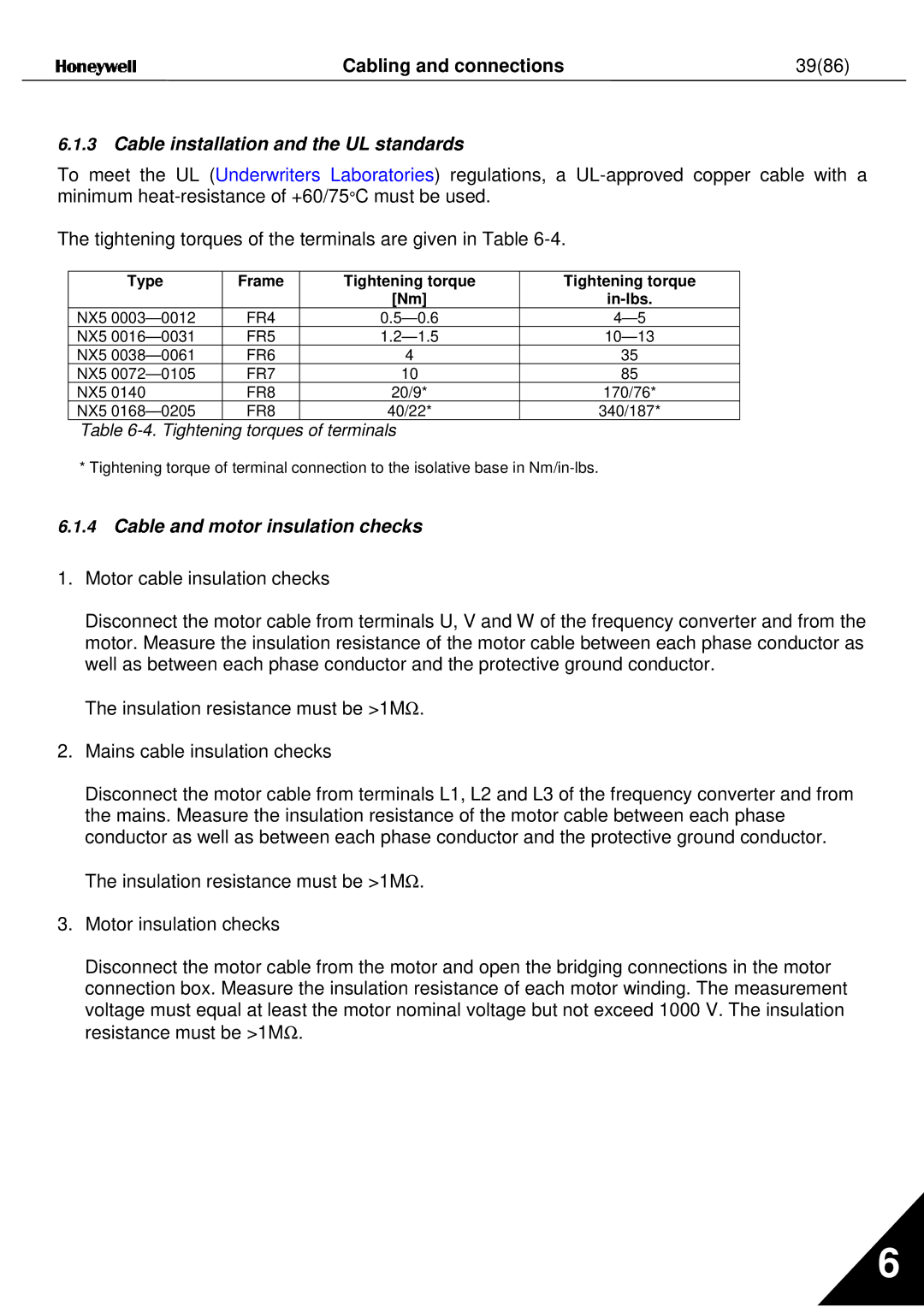

The tightening torques of the terminals are given in Table

Type | Frame | Tightening torque | Tightening torque |

|

| [Nm] | |

NX5 | FR4 | ||

NX5 | FR5 | ||

NX5 | FR6 | 4 | 35 |

NX5 | FR7 | 10 | 85 |

NX5 0140 | FR8 | 20/9* | 170/76* |

NX5 | FR8 | 40/22* | 340/187* |

Table

* Tightening torque of terminal connection to the isolative base in

6.1.4Cable and motor insulation checks

1.Motor cable insulation checks

Disconnect the motor cable from terminals U, V and W of the frequency converter and from the motor. Measure the insulation resistance of the motor cable between each phase conductor as well as between each phase conductor and the protective ground conductor.

The insulation resistance must be >1MΩ .

2.Mains cable insulation checks

Disconnect the motor cable from terminals L1, L2 and L3 of the frequency converter and from the mains. Measure the insulation resistance of the motor cable between each phase conductor as well as between each phase conductor and the protective ground conductor.

The insulation resistance must be >1MΩ .

3.Motor insulation checks

Disconnect the motor cable from the motor and open the bridging connections in the motor connection box. Measure the insulation resistance of each motor winding. The measurement

voltage must equal at least the motor nominal voltage but not exceed 1000 V. The insulation resistance must be >1MΩ .

6