Synchronization (Option) | The setup order for the different synchronization options |

|

|

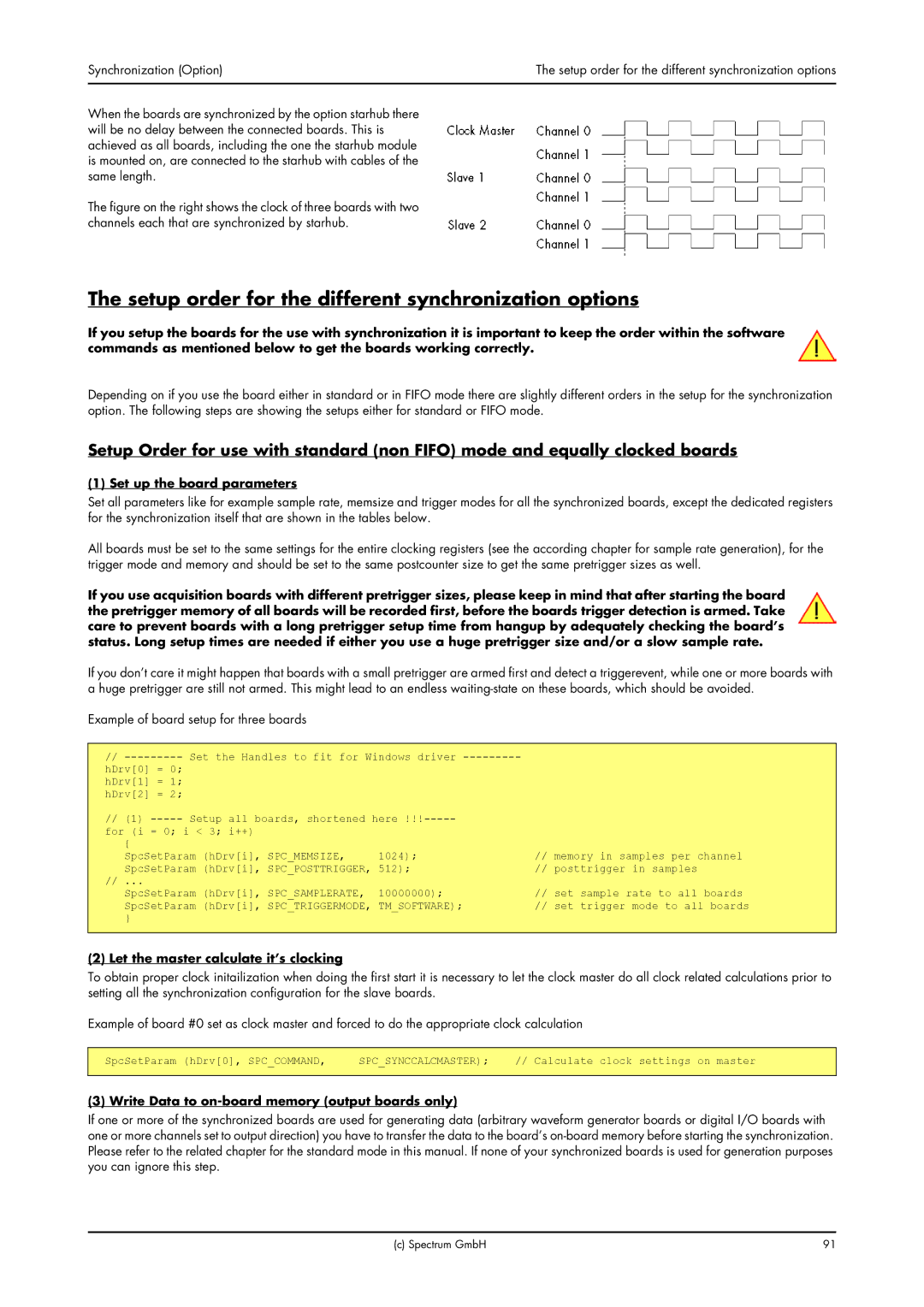

When the boards are synchronized by the option starhub there will be no delay between the connected boards. This is achieved as all boards, including the one the starhub module is mounted on, are connected to the starhub with cables of the same length.

The figure on the right shows the clock of three boards with two channels each that are synchronized by starhub.

The setup order for the different synchronization options

If you setup the boards for the use with synchronization it is important to keep the order within the software commands as mentioned below to get the boards working correctly.

Depending on if you use the board either in standard or in FIFO mode there are slightly different orders in the setup for the synchronization option. The following steps are showing the setups either for standard or FIFO mode.

Setup Order for use with standard (non FIFO) mode and equally clocked boards

(1) Set up the board parameters

Set all parameters like for example sample rate, memsize and trigger modes for all the synchronized boards, except the dedicated registers for the synchronization itself that are shown in the tables below.

All boards must be set to the same settings for the entire clocking registers (see the according chapter for sample rate generation), for the trigger mode and memory and should be set to the same postcounter size to get the same pretrigger sizes as well.

If you use acquisition boards with different pretrigger sizes, please keep in mind that after starting the board the pretrigger memory of all boards will be recorded first, before the boards trigger detection is armed. Take care to prevent boards with a long pretrigger setup time from hangup by adequately checking the board’s status. Long setup times are needed if either you use a huge pretrigger size and/or a slow sample rate.

If you don’t care it might happen that boards with a small pretrigger are armed first and detect a triggerevent, while one or more boards with a huge pretrigger are still not armed. This might lead to an endless

Example of board setup for three boards

//

hDrv[0] = 0; hDrv[1] = 1; hDrv[2] = 2;

//(1)

for (i = 0; i < 3; i++) |

|

|

{ | 1024); | // memory in samples per channel |

SpcSetParam (hDrv[i], SPC_MEMSIZE, | ||

SpcSetParam (hDrv[i], SPC_POSTTRIGGER, 512); | // posttrigger in samples | |

// ... | 10000000); | // set sample rate to all boards |

SpcSetParam (hDrv[i], SPC_SAMPLERATE, | ||

SpcSetParam (hDrv[i], SPC_TRIGGERMODE, TM_SOFTWARE); | // set trigger mode to all boards | |

} |

|

|

(2) Let the master calculate it’s clocking

To obtain proper clock initailization when doing the first start it is necessary to let the clock master do all clock related calculations prior to setting all the synchronization configuration for the slave boards.

Example of board #0 set as clock master and forced to do the appropriate clock calculation

SpcSetParam (hDrv[0], SPC_COMMAND, | SPC_SYNCCALCMASTER); | // Calculate clock settings on master |

|

|

|

(3) Write Data to on-board memory (output boards only)

If one or more of the synchronized boards are used for generating data (arbitrary waveform generator boards or digital I/O boards with one or more channels set to output direction) you have to transfer the data to the board’s

(c) Spectrum GmbH | 91 |