ULTRA HIGH EFFICIENCY POWER VENT/POWER DIRECT VENT - SERVICE MANUAL

FAULT MESSAGES (CONT)

DISPLAYED MESSAGE | CHECK/REPAIR | |

CONDITION/INDICATES | ||

| ||

|

| |

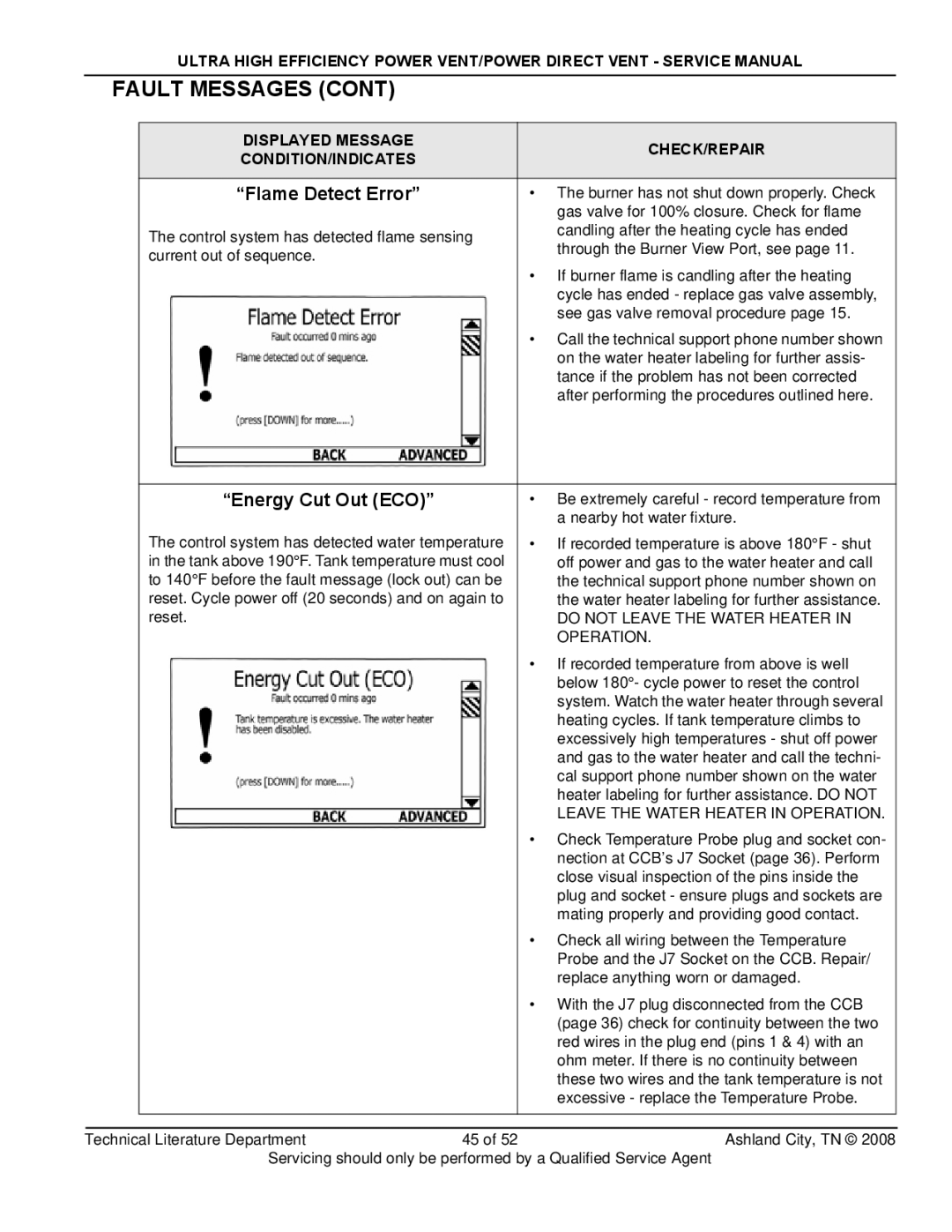

“Flame Detect Error” | • The burner has not shut down properly. Check | |

| gas valve for 100% closure. Check for flame | |

The control system has detected flame sensing | candling after the heating cycle has ended | |

through the Burner View Port, see page 11. | ||

current out of sequence. | ||

• If burner flame is candling after the heating | ||

| ||

| cycle has ended - replace gas valve assembly, | |

| see gas valve removal procedure page 15. | |

| • Call the technical support phone number shown | |

| on the water heater labeling for further assis- | |

| tance if the problem has not been corrected | |

| after performing the procedures outlined here. |

| “Energy Cut Out (ECO)” |

| • Be extremely careful - record temperature from |

|

|

| a nearby hot water fixture. |

| The control system has detected water temperature | • If recorded temperature is above 180°F - shut | |

| in the tank above 190°F. Tank temperature must cool | off power and gas to the water heater and call | |

| to 140°F before the fault message (lock out) can be | the technical support phone number shown on | |

| reset. Cycle power off (20 seconds) and on again to | the water heater labeling for further assistance. | |

| reset. |

| DO NOT LEAVE THE WATER HEATER IN |

|

|

| OPERATION. |

|

|

| • If recorded temperature from above is well |

|

|

| below 180°- cycle power to reset the control |

|

|

| system. Watch the water heater through several |

|

|

| heating cycles. If tank temperature climbs to |

|

|

| excessively high temperatures - shut off power |

|

|

| and gas to the water heater and call the techni- |

|

|

| cal support phone number shown on the water |

|

|

| heater labeling for further assistance. DO NOT |

|

|

| LEAVE THE WATER HEATER IN OPERATION. |

|

|

| • Check Temperature Probe plug and socket con- |

|

|

| nection at CCB’s J7 Socket (page 36). Perform |

|

|

| close visual inspection of the pins inside the |

|

|

| plug and socket - ensure plugs and sockets are |

|

|

| mating properly and providing good contact. |

|

|

| • Check all wiring between the Temperature |

|

|

| Probe and the J7 Socket on the CCB. Repair/ |

|

|

| replace anything worn or damaged. |

|

|

| • With the J7 plug disconnected from the CCB |

|

|

| (page 36) check for continuity between the two |

|

|

| red wires in the plug end (pins 1 & 4) with an |

|

|

| ohm meter. If there is no continuity between |

|

|

| these two wires and the tank temperature is not |

|

|

| excessive - replace the Temperature Probe. |

|

|

|

|

|

|

|

|

Technical Literature Department | 45 of 52 | Ashland City, TN © 2008 | |

Servicing should only be performed by a Qualified Service Agent