ULTRA HIGH EFFICIENCY POWER VENT/POWER DIRECT VENT - SERVICE MANUAL

AIR PRESSURE SWITCH TESTING (CONT)

Pressure Test

The Pressure Test is necessary when the air pressure switch in question has passed the Normal State Test but failed the Operational State Test (see page 21). This test requires a digital manometer (see Tool Requirements page 3 and the images on page 23).

Before performing this test examine the sensing tube connections on the water heater’s sensing ports and on the pressure switch (see page 19). Check for wear, leaks, kinks, or any kind of debris or condensate in the sensing tubes, repair/replace as necessary.

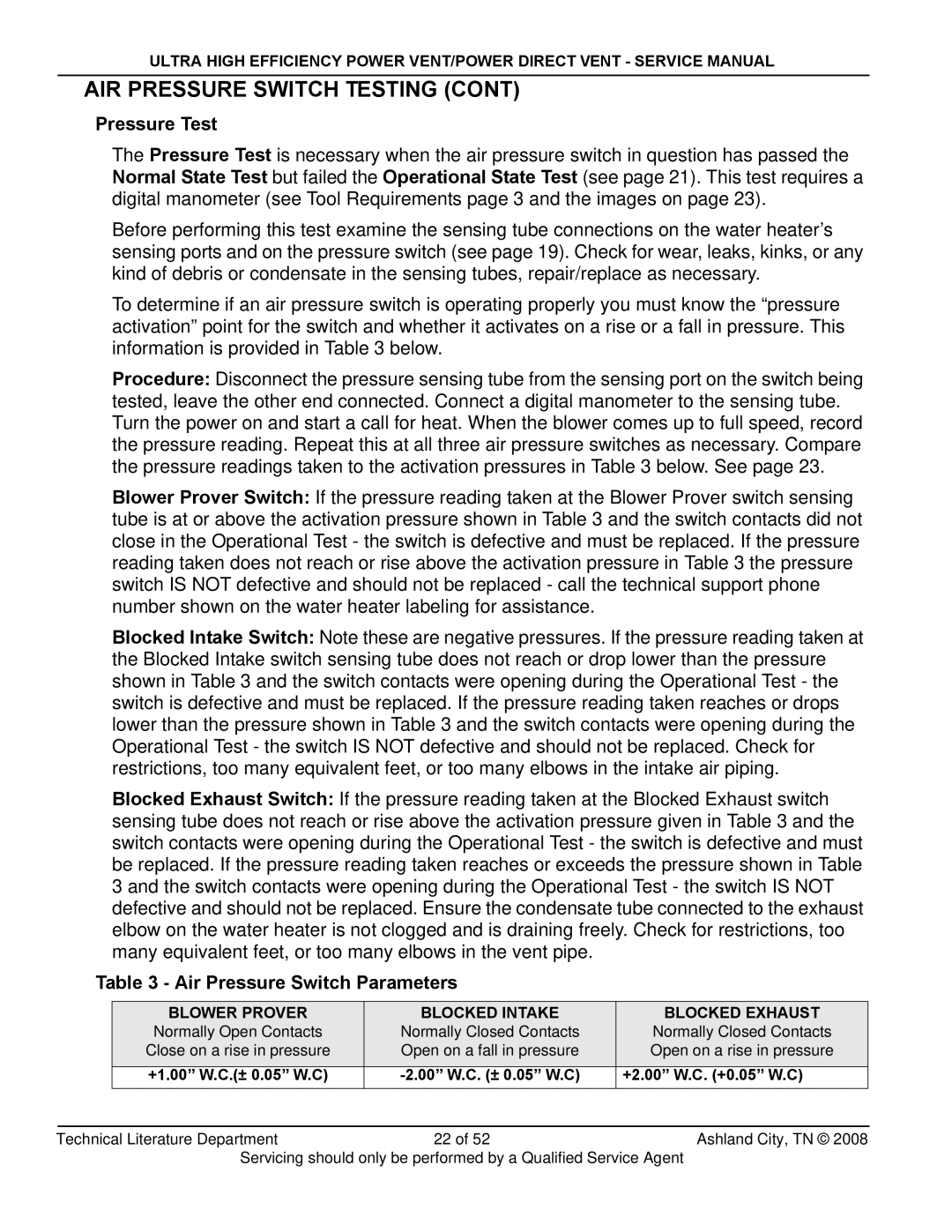

To determine if an air pressure switch is operating properly you must know the “pressure activation” point for the switch and whether it activates on a rise or a fall in pressure. This information is provided in Table 3 below.

Procedure: Disconnect the pressure sensing tube from the sensing port on the switch being tested, leave the other end connected. Connect a digital manometer to the sensing tube. Turn the power on and start a call for heat. When the blower comes up to full speed, record the pressure reading. Repeat this at all three air pressure switches as necessary. Compare the pressure readings taken to the activation pressures in Table 3 below. See page 23.

Blower Prover Switch: If the pressure reading taken at the Blower Prover switch sensing tube is at or above the activation pressure shown in Table 3 and the switch contacts did not close in the Operational Test - the switch is defective and must be replaced. If the pressure reading taken does not reach or rise above the activation pressure in Table 3 the pressure switch IS NOT defective and should not be replaced - call the technical support phone number shown on the water heater labeling for assistance.

Blocked Intake Switch: Note these are negative pressures. If the pressure reading taken at the Blocked Intake switch sensing tube does not reach or drop lower than the pressure shown in Table 3 and the switch contacts were opening during the Operational Test - the switch is defective and must be replaced. If the pressure reading taken reaches or drops lower than the pressure shown in Table 3 and the switch contacts were opening during the Operational Test - the switch IS NOT defective and should not be replaced. Check for restrictions, too many equivalent feet, or too many elbows in the intake air piping.

Blocked Exhaust Switch: If the pressure reading taken at the Blocked Exhaust switch sensing tube does not reach or rise above the activation pressure given in Table 3 and the switch contacts were opening during the Operational Test - the switch is defective and must be replaced. If the pressure reading taken reaches or exceeds the pressure shown in Table 3 and the switch contacts were opening during the Operational Test - the switch IS NOT defective and should not be replaced. Ensure the condensate tube connected to the exhaust elbow on the water heater is not clogged and is draining freely. Check for restrictions, too many equivalent feet, or too many elbows in the vent pipe.

Table 3 - Air Pressure Switch Parameters

BLOWER PROVER | BLOCKED INTAKE | BLOCKED EXHAUST |

Normally Open Contacts | Normally Closed Contacts | Normally Closed Contacts |

Close on a rise in pressure | Open on a fall in pressure | Open on a rise in pressure |

|

|

|

+1.00” W.C.(± 0.05” W.C) | +2.00” W.C. (+0.05” W.C) |

Technical Literature Department | 22 of 52 | Ashland City, TN © 2008 |

Servicing should only be performed by a Qualified Service Agent |

| |