Tipo a cassetta con scarico daria a 1 vie

MMU-AP0071YH,RBC-UY135PGMMU-AP0091YH MMU-AP0121YH

Modelo de casete de distribución de aire de 1 vías

Descarga de ar tipo cassete de 1 vias

HFC R410A R22

Adoption of NEW Refrigerant

Sommaire

Separate sold parts

Refrigerant piping

Part name

Shape Usage

New Refrigerant Air Conditioner Installation

Precautions for Safety

To Disconnect the Appliance from Main Power Supply

Connect the connecting wire correctly

Inappropriate grounding may cause electric shock

Precautions for Safety

Installation space

Selection of Installation Place

Selection of Installation Place

Installation of Indoor Unit

Case of wireless type

Removal of transporting rubbers

External view

Wired remote controller RBC-AMT21E

Ceiling opening and installation of hanging bolts

Installation of Indoor Unit

How to use the attached installation pattern

Installation of hanging bolts

Installation of ceiling panel Sold separately

Installation of indoor unit

Pipe material/Insulator and size

Drain Piping Work

Connection of drain pipe

Drain up

When the electric work has finished

Heat insulating of pipe connecting part

When the electric work has not finished

Check the draining

Refrigerant Piping

Piping material and dimensions

Permissible pipe length and permissible height difference

Pipe forming/End positioning

Airtight test/Air purge, etc

Connection of refrigerant pipe

Open fully valves of the outdoor unit Gas leak check

Heat insulating process

Electric Work

Be sure to connect earth wire. Grounding work

Be sure to install an earth leakage breaker

Indoor unit power supply

Power supply specifications

Indoor/Outdoor inter-unit wiring, Central controller wiring

Remote controller wiring

How to remove cover of the electric parts box

Treating of wiring connecting port

Electric Work

Cable connection

Wiring between indoor and outdoor units

Remote controller wiring

Address setup

Wiring on the ceiling panel

Basic operation procedure for setup exchange

Exchange of applicable control setup

Applicable Controls

Notification

Group control

Change of lighting term of filter sign

To secure better effect of heating

Case of wired remote controller

How to execute test operation

Test RUN

Before test operation

Procedure

Case of wireless remote controller

Confirmation and check

Troubleshooting

Confirmation of error history

Terminology

Check code list

Check method

Troubleshooting

TCC-LINK Toshiba Carriea Cominication Link

Error detected by TCC-LINK central control device

Display on sensor part of wireless

Display on wired remote controller

New check code

Special mention

Daily maintenance

Maintenance

Cleaning of air filter

Way Air Discharge Cassette Compact Type

Piè ces vendues sé paré ment

Tuyaux de ré frigé rant

Pour dé connecter l’appareil du secteur

Mesures DE Securite

Avertissement

Ré servé

Mesures DE Securite

Espace requis pour l’installation

Selection DU Lieu D’INSTALLATION

Selection DU Lieu D’INSTALLATION

Installation DE L’UNITE Interieure

Enlè vement des caoutchoucs de transport

Sur les types sans-fil

100 850 400 200 120 140 235 Métal de support

Vue exté rieure

Installation du boulon de suspension

Installation DE L’UNITE Interieure

Installation de la té lé commande vendue sé paré ment

Comment utiliser le gabarit de montage joint

Fixez solidement

Installation de l’unité inté rieure

Installation du panneau pour plafond vendu sé paré ment

Raccordement du tuyau d’é vacuation

Tuyauterie/Isolant et dimension

Evacuation ascendante

Tuyauterie

Lorsque l’installation é lectrique n’est pas terminé e

Lorsque l’installation é lectrique est terminé e

Vé rification de l’é vacuation

Isolation thermique des raccords des tuyaux

Tuyaux DE RÉ Frigé Rant

Tuyauterie et dimensions

Mise en forme/Pose définitive des tuyaux

Evasement

Test d’é tanché ité /Purge d’air, etc

Raccordement du tuyau de ré frigé rant

Procé dé de calorifugeage

Marge de projection de l’é vasement B Unité mm

Assurez-vous de raccorder le fil de terre. Mise à la terre

Travaux D’É Lectricité

Alimentation é lectrique de l’unité inté rieure

Câ bles de la té lé commande *4

Caracté ristiques de l’alimentation é lectrique

Raccordement des câ bles

Travaux D’É Lectricité

Comment dé monter le couvercle du boîtier é lectrique

Traitement des ports de connexion des câ bles

Configuration de l’adresse

Raccordement des té lé commandes

Raccordement sur le panneau de plafond

Sché ma de câ blage

Procé dure de base pour modifier la configuration

Commandes Utilisables

Modification de la configuration de la commande possible

Pour garantir un meilleur chauffage

Commande de groupe

En cas de té lé commande avec fil

Mode d’exé cution d’un essai de fonctionnement

Essai DE Fonctionnement

Remarque

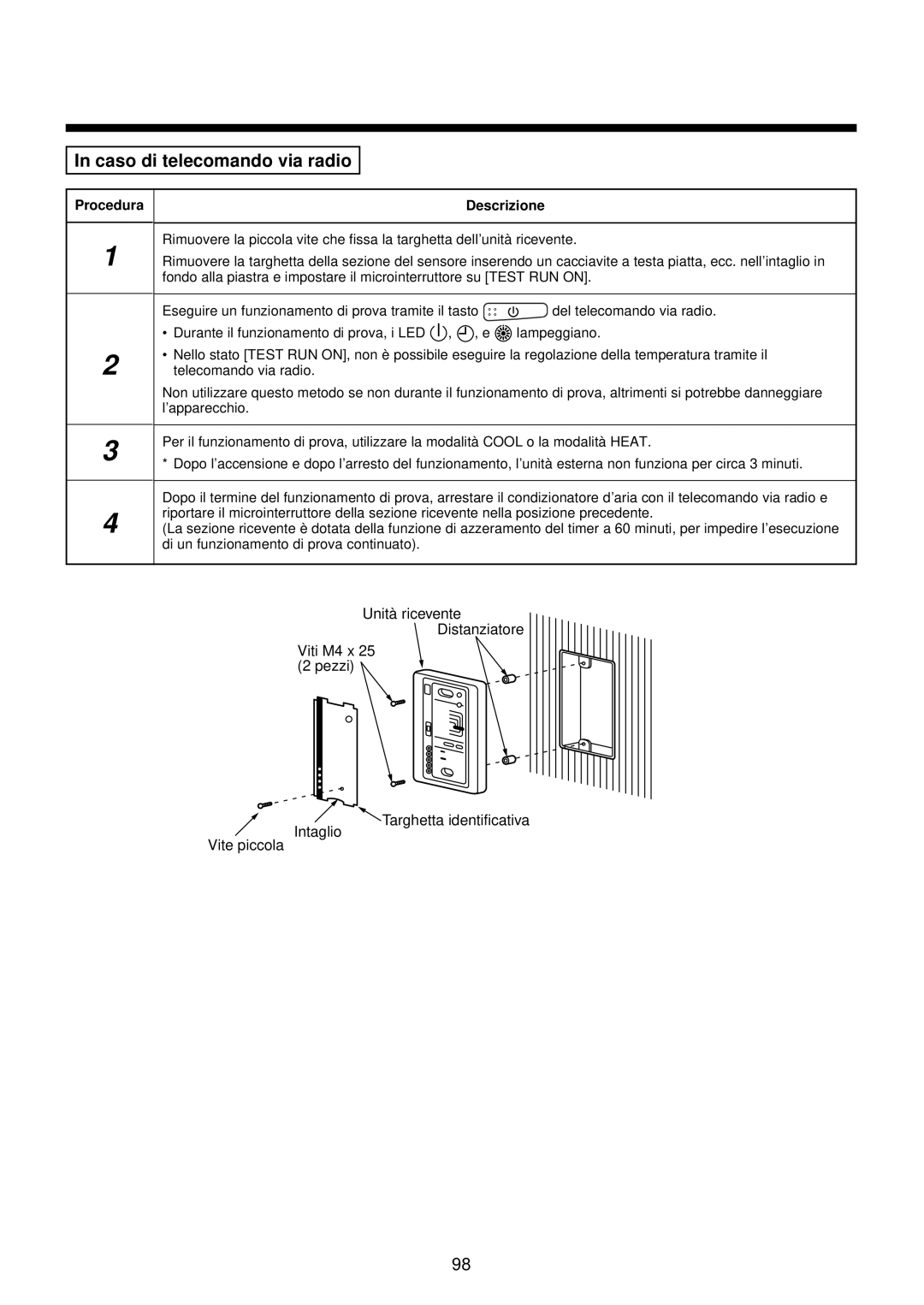

Petite vis

Avec une té lé commande sans-fil

Récepteur Entretoise Vis M4 × 25 2 pièces Encoche

Confirmation et vé rification

DÉ Pannage

Confirmation de l’historique de pannes

Mé thode de vé rification

Terminologie

Liste des codes de vé rification

MG-SW

DÉ Pannage

IPDU, I/F

Affichage sur capteur té lé commande sans-fil

Affichage sur té lé commande à fil

Nouveau code de vé rification

Mention spé ciale

Entretien quotidien

Entretien

Type compact cassette à 1 voie de refoulement de l’air

Nettoyage du filtre à air

Kühlmittel-Leitungssystem

Getrennt erhältliche Teile

Vorsicht Trennen des Gerä ts von der Hauptstromversorgung

Sicherheitsvorkehrungen

Warnung

Sicherheitsvorkehrungen

Platzbedarf

Auswahl DES Aufstellungsortes

Vorsicht

Auswahl DES Aufstellungsortes

Installation DER Raumeinheit

Ausbau der Transportsicherungen

Fü r drahtlose Fernbedienungen

Gerä teansicht

Benutzung der Installationsvorlage

Installation DER Raumeinheit

Installation der Aufhä ngebolzen

Installation der Fernbedienung getrennt erhä ltlich

Installation der Deckenkassette gesondert zu kaufen

Installation der Inneneinheit

Kondenswasserablauf nach oben

Rohrmaterial/Isolation und Abmessung

Anschluss des Kondensatschlauchs

Wenn die Elektroinstallation noch nicht fertiggestellt ist

Nach Fertigstellung der Elektroinstallation

Ablauf ü berprü fen

Wä rmeisolierung der Rohrverbindungen

Erlaubte Rohrleitungslä ngen und erlaubte Hö hendifferenzen

KÜ Hlmittelleitungen

Rohrmaterial und Abmessungen

Biegen und Positionieren

Dichtetest/Entlü ftung usw

Anschluss der Kü hlmittelleitung

Wä rmeisolierung

Bö rdelhö he B Einheit mm Starr Kupplung

Verlegen Sie auch eine Masseleitung. Masse anschließen

Elektroarbeiten

Verkabelung der Fernbedienung

Spezifikation der Stromversorgung

Stromversorgung Raumeinheit

Kabelanschlü sse

Elektroarbeiten

Ffnen der Abdeckung des Schaltkastens

Abdichtung der Kabeldurchfü hrung

Verbindungskabel zwischen Raum- und Außeneinheit

Verkabelung der Fernbedienung

Adress-Einstellung

Verkabelung des Deckenrahmens

Hinweise

Steuerungsmö Glichkeiten

Nderung der Steuerungsvorgaben

Automatische Adressierung

Verbesserung der Heizleistung

Nderung der Zeitvorgabe fü r die Filterwarnleuchte

Gruppensteuerung

Für den Code in Vorgehensweise 3 geben Sie 01 ein

Hinweis

Testlauf

Vorbereitung

Ablauf des Tests

Beschreibung

Testlauf

Infrarot-Fernbedienung

Bestä tigung und Prü fung

Fehlersuche

Aufruf des Fehlerspeichers

Prü fmethode

AI-NET

Liste der Fehlercodes

Fehlersuche

TCC-LINK Toshiba Carrier Communication Link

Fehler durch zentrale Ü berwachung TCC-LINK erkannt

Anzeige bei verdrahteter Fernbedienung

Neuer Prü fcode

Anzeige auf Empfangsteil der Infrarot-Fernbedienung

Spezielle Bemerkung

Wege-Kassetten-Kompakt-Modell

Wartung

Tä gliche Wartung Reinigen des Luftfilters

Wird auf der Fernbedienung

Tubazioni del refrigerante

Parti da acquistare a parte

Nome delle parti Forma Utilizzo

Nome delle parti Forma

Avvertenza

Precauzioni PER LA Sicurezza

Ttenzione

Collegare il cavo di connessione in modo corretto

Una messa a terra non corretta può causare scosse elettriche

Precauzioni PER LA Sicurezza

Evitare l’installazione nei posti seguenti

Scelta DEL Posto D’INSTALLAZIONE

Spazio per l’installazione

Scelta DEL Posto D’INSTALLAZIONE

Installazione DELL’UNITÀ Interna

Rimozione dei gommini di protezione durante il trasporto

Nel caso del tipo via radio

Telecomando via cavo RBC-AMT21E

Vista esterna

Come usare la sagomo per installazione fornita in dotazione

Installazione DELL’UNITÀ Interna

Installazione del bullone di sospensione

Installazione del pannello del soffitto in vendita a parte

Fissare saldamente

Installazione dellunità interna

Materiale per tubazioni/Isolamento e formato

Lavoro PER Tubazione DI Scarico

Connessione del tubo di scarico

Scarico

Se i collegamenti elettrici non sono stati completati

Controllare lo scarico

Se i collegamenti elettrici sono stati completati

Dimensione misuratore dia. svasatura a Unità mm

Materiale per tubature e dimensioni

Tubazioni DEL Refrigerante

Formatura tubi/Posizionamento estremità

Prove di tenuta d’aria/Sfiato aria, ecc

Connessione del tubo del refrigerante

Procedura per isolamento termico

Imperial Tipo con dado ad alette

Collegamenti Elettrici

Installare un interruttore di collegamento a terra

Collegamenti elettrici del telecomando

Dati tecnici per alimentazione elettrica

Alimentazione elettrica dell’unità interna

Come trattare la porta di connessione fili

Collegamenti Elettrici

Collegamento dei cavi

Posa in opera dei cavi per il telecomando

Schema dei collegamenti elettrici

Collegamenti elettrici fra unità interna e esterna

Impostazione dindirizzamento

Avviso

Comandi Applicabili

Scambio di impostazioni dei comandi applicabili

Indirizzamento automatico

Per garantire una resa migliore del riscaldamento

Modifica del tempo di accensione del simbolo del filtro

Controllo di gruppo

Per il codice di voce del passo 3 , specificare

Nota

Funzionamento DI Prova

Prima del funzionamento di prova

Come avviare il funzionamento di prova

Caso di telecomando via radio

Conferma della casistica di errori

Risoluzione DEI Problemi

Conferma e controllo

Metodo di controllo

Terminologia

Lista dei codici di controllo

101

Risoluzione DEI Problemi

102

Differenza tra codice di controllo nuovo e sistema corrente

Nuovo codice di controllo

Display su telecomando via cavo

Display su parte sensore di telecomando via radio

Manutenzione giornaliera

Manutenzione

Tipo compatto a cassetta con scarico daria a 1 via

Pulizia del filtro dellaria

Tubería de refrigerante

Componentes vendidos por separado

Nombre del componente Cantidad Forma Utilización

Nombre del componente Cantidad Forma

Precaució N

Precauciones Para SU Seguridad

Advertencia

Conecte el cable de conexió n correctamente

Precauciones Para SU Seguridad

Evite la instalació n en los siguientes lugares

Selecció N DEL Lugar DE Instalació N

Espacio de instalació n

En el caso de mando a inalá mbrico

Instalació N DE LA Unidad Interior

Selecció N DEL Lugar DE Instalació N

Vista exterior

Có mo utilizar el patró n de instalació n adjunto

Instalació N DE LA Unidad Interior

Instalació n del perno de suspensió n

Instalació n del mando a distancia vendido por separado

Instalació n del panel de techo vendido por separado

Instalació n de la unidad interior

Material del tubo / Aislante y tamañ o

Canalizació N DE Drenaje

Conexió n del tubo de drenaje

Drenaje ascendente

Aislamiento té rmico de la parte de conexió n de los tubos

Compruebe el drenaje

Una vez preparada la canalización de drenaje

Si ya se ha completado la instalació n elé ctrica

Tubería DE Regrigerante

Material y dimensiones de la tubería

Longitud del tubo y diferencia de altura permisibles

Moldeado de los tubos / Posició n final

Prueba de hermetizado, purga de aire, etc

Conexió n del tubo de refrigerante

Proceso de aislamiento té rmico

Margen de proyecció n en el abocinado B unidad mm

Instale un disyuntor de fugas a tierra

Instalació N ELÉ Ctrica

Asegú rese de conectar todos los cables. Conexió n a tierra

Cableado del mando a distancia

Especificaciones de la alimentació n elé ctrica

Alimentació n elé ctrica de la unidad interior

Conexió n de los cables

Instalació N ELÉ Ctrica

Có mo extraer la tapa del cuadro elé ctrico

Tratamiento del orificio de conexió n del cableado

Diagrama del cableado

Configuració n de las identificaciones

Cableado del mando a distancia

Cableado entre las unidades interior y exterior

Notificació N

Cambio en la configuració n de los controles aplicables

Controles Aplicables

Cambiar momento de encendido de la señ al de filtro

Configuració n De la señ al de filtro 0000 Ninguno 0001

Para mejorar el efecto calefactor

Control grupal

Antes de llevar a cabo la prueba

Prueba DE Funcionamiento

Có mo realizar una prueba de funcionamiento

En el caso de mando a distancia con cable

Tornillo pequeño

En el caso de mando a distancia inalá mbrico

Confirmació n del historial de errores

Resolució N DE Problemas

Confirmació n y verificació n

Mé todo de verificació n

Terminología

Lista de có digos de verificació n

127

Resolució N DE Problemas

128

Nuevo có digo de verificació n

Modelo compacto de cassette con descarga de aire de 1 vía

Mantenimiento

Mantenimiento diario Limpieza del filtro de aire

Desaparecerá el mensaje

Tubagem de refrigerante

Peç as vendidas em separado

Nome da peça Quant Forma Utilização

Nome da peça Quant Forma

Precauçõ ES

Precauçõ ES DE Seguranç a

Aviso

Instalaçã o de Ar Condicionado de Novo Refrigerante

133

Cuidado

Selecçã O do Local DE Instalaçã O

Espaç o de instalaçã o

Evite instalar a unidade nos seguintes locais

Selecçã O do Local DE Instalaçã O

Instalaçã O DA Unidade Interior

Remoçã o das borrachas de transporte

No caso do tipo sem cabos

136

Abertura do tecto e instalaçã o de parafusos de suspensã o

Instalaçã O DA Unidade Interior

Como utilizar o esquema de instalaçã o fornecido

Instalaçã o de parafuso de suspensã o

Fixe firmemente

Instalaçã o da unidade interior

Instalaçã o do painel de tecto vendido separadamente

Ligaçã o do tubo de drenagem

Material dos tubos/Isolante e tamanho

Drenagem ascendente

Material

Isolamento té rmico da peç a de ligaçã o do tubo

Verificar a drenagem

Depois de concluídos os trabalhos de electricidade

Antes de concluídos os trabalhos de electricidade

Material e dimensõ es de tubagem

Tubagem DE Refrigerante

Definiçã o da Tubagem Posiçã o dos Extremos

Alargamento

Teste de hermeticidade/Purga de ar, etc

Ligaçã o do tubo de refrigerante

Processo de isolamento té rmico

Margem de projecçã o no alargamento B Unidade mm

Nã o se esqueç a de ligar o cabo de terra. Ligaçã o à terra

Trabalhos DE Electricidade

Cabos do controlador remoto

Especificaçõ es da alimentaçã o elé ctrica

Alimentaçã o elé ctrica da unidade interior

Ligaçã o de cabos

Trabalhos DE Electricidade

Como remover a cobertura da caixa das partes elé ctricas

Tratamento da porta de ligaçã o dos cabos

Ligaçõ es do controlador remoto

Diagrama de ligaçõ es

Ligaçõ es entre as unidades interiores e exteriores

Definiçã o do endereç o

Controlos Aplicá Veis

Troca da configuraçã o de controlo aplicá vel

Endereç amento automá tico

Descriçã o

Mude o tempo de iluminaçã o do sinal do filtro

Configuraçã o

Para garantir um melhor efeito do aquecimento

Controlo de grupo

Avisos

Teste DE Funcionamento

Antes do teste de funcionamento

Como efectuar um teste

Procedimento

No caso de controlador remoto sem cabos

Parafuso pequeno

Confirmaçã o e verificaçã o

Resoluçã O DE Problemas

Confirmaçã o de historial de erros

Mé todo de Verificaçã o

Lista de có digos de erros

153

Resoluçã O DE Problemas

Erro detectado pelo dispositivo de controlo central TCC-LINK

Visor no controlador remoto com cabos

Novo có digo de verificaçã o

Visor na parte do sensor sem cabos

Referê ncia especial

Tipo Cassete compacta de Descarga de Ar de 1 vias

Manutençã O

Aparecer no controlador remoto, deve proceder

Refrigeraçã o/aquecimento

Koelmiddelleidingen

Niet meegeleverde onderdelen

LET OP

Installeren van een airconditioner met een nieuw koelmiddel

Waarschuwing

Het apparaat loskoppelen van de netvoeding

Voorzorgsmaatregelen Voor UW Veiligheid

Installeer de airconditioner niet op de volgende plaatsen

Installatieruimte

Keuze VAN DE Locatie Voor DE Installatie

Installatie VAN DE Binnenunit

Verwijdering van de transportrubbers

Bij een draadloos model

Bekabelde afstandsbediening RBC-AMT21E

Buitenaanzicht

Zo gebruikt u het meegeleverde installatiesjabloon

Installatie VAN DE Binnenunit

Aanbrengen van de plafondopening en de ophangbouten

Monteren van de ophangbouten

Montage van het plafondpaneel niet meegeleverd

Installatie van de binnenunit

Leidingmateriaal/isolatie en afmeting

Afvoerleidingen

Aansluiten van de afvoerleiding

Stijgleiding

Warmte-isolatie van de pijpaansluiting

Controleer de afvoer

Wanneer de elektrische bekabeling is aangesloten

Wanneer de elektrische bekabeling niet is aangesloten

Toegestane leidinglengte en hoogteverschil

Koelmiddelleidingen

Leidingmateriaal en -afmetingen

Leidingen buigen Bepalen van het uiteinde van de leidingen

Gasdichtheid testen Ontluchten enzovoort

Aansluiten van koelmiddelleidingen

Isoleren

Uitstekende leidinglengte bij trompen B eenheid mm

Controleer of de aardingsaansluiting is gemonteerd. Aarding

Installeer altijd een aardlekschakelaar

Elektrische Bedrading

Bekabeling voor de afstandsbediening

Voedingspecificaties

Voeding binnenunit

Behandeling van de aansluitopening voor de bedrading

Elektrische Bedrading

Kabelaansluitingen

Bekabeling van de afstandsbediening

Aansluitschema

Bekabeling tussen de binnen- en buitenunits

Adres instellen

Belangrijk

Bedieningselementen

Wijzigen van de instellingen

Automatische adressering

Tijdstip waarop de

De verwarmingscapaciteit optimaliseren

Groepsbediening

Opmerking

Werkingstest

Voordat u een werkingstest uitvoert

Zo voert u de werkingstest uit

Bij gebruik van een draadloze afstandsbediening

Controles

Storingen Verhelpen

Storingscodes opslaan

Controlemethode

Hulpcode

Storingscodelijst

179

Storingen Verhelpen

180

Nieuwe storingscode

Dagelijks onderhoud

Onderhoud

Compact model voor inbouw in plafond met 1 uitblaasopening

Het luchtfilter reinigen

Óùëçíþóåéò øõêôéêïý ìÝóïõ

ÅîáñôÞìáôá ðïõ ðùëïýíôáé îå÷ùñéóôÜ

Ðñïöõëáîåéó Áóöáëåéáó

Ðñïöõëáîåéó Áóöáëåéáó

×þñïò åãêáôÜóôáóçò

Åðéëïãç ÔÏÕ ×ÙÑÏÕ Åãêáôáóôáóçó

Ãéá ôçí ðåñßðôùóç áóýñìáôïõ ôýðïõ

Áöáßñåóç ëÜóôé÷ùí ìåôáöïñÜò

ÅîùôåñéêÞ üøç

395

Ðþò íá ÷ñçóéìïðïéÞóåôå ôï ðñïóáñôçìÝíï ðñüôõðï åãêáôÜóôáóçò

¢íïéãìá ïñïöÞò êáé åãêáôÜóôáóç ôùí ìðïõëïíéþí áíÜñôçóçò

ÅãêáôÜóôáóç ôïõ ìðïõëïíéïý áíÜñôçóçò

ÅãêáôÜóôáóç ôïõ ôçëå÷åéñéóôçñßïõ Ðùëåßôáé îå÷ùñéóôÜ

‹Ù˘ÎÂıÒ‹ÙÔı

ÅãêáôÜóôáóç ôçò åóùôåñéêÞò ìïíÜäáò

ÅãêáôÜóôáóç ôïõ öáôíþìáôïò ïñïöÞò

Ðùëåßôáé îå÷ùñéóôÜ

ÁðïóôñÜããéóç

Óýíäåóç óùëÞíá áðïóôñÜããéóçò

¸ Ô ı

¸ëåã÷ïò ôçò áðïóôñÜããéóçò

Èåñìïìüíùóç ôïõ ôìÞìáôïò óýíäåóçò ôïõ óùëÞíá

Ìïñöïðïßçóç óùëÞíùí / ÈÝóç Üêñùí

Åðéôñåðüìåíï ìÞêïò óùëÞíá êáé åðéôñåðüìåíç äéáöïñÜ ýøïõò

Õëéêü êáé äéáóôÜóåéò óùëÞíùóçò

Äéáäéêáóßá èåñìïìüíùóçò

Óýíäåóç ôïõ óùëÞíá áðïóôñÜããéóçò

ÄïêéìÞ áåñïóôåãáíüôçôáò / ÅêêÝíùóç áÝñá, êëð

$ Çëåêôñéêç Åñãáóéá

Ðáñï÷Þ ñåýìáôïò ôçò åóùôåñéêÞò ìïíÜäáò

ÐñïäéáãñáöÝò ðáñï÷Þò ñåýìáôïò

×åéñéóìüò ôçò èýñáò ôçò êáëùäßùóçò óýíäåóçò

Óýíäåóç êáëùäßùí

Ðþò íá áöáéñÝóôå ôï êÜëõììá ôïõ çëåêôñéêïý êïõôéïý

Êáëùäßùóç ìåôáîý åóùôåñéêÞò êáé åîùôåñéêÞò ìïíÜäáò

Êáëùäßùóç ôçëå÷åéñéóôçñßïõ

Ñýèìéóç ôçò äéåýèõíóçò

Êáëùäßùóç óôï öÜôíùìá ôçò ïñïöÞò

ÁëëáãÞ ñõèìßóåùí åöáñìüóéìùí åíôïëþí

Åöáñìïóéìïé ÅËÅÃ×ÏÉ

Ïìáäéêüò Ýëåã÷ïò

ÁëëáãÞ ôïõ ÷ñüíïõ áíÜììáôïò ôïõ óÞìáôïò ôïõ ößëôñïõ

Ãéá íá åîáóöáëßóåôå êáëýôåñá áðïôåëÝóìáôá óôç èÝñìáíóç

Ðþò íá êÜíåôå ôç äïêéìÞ ëåéôïõñãßáò

Ðñéí ôç äéáäéêáóßá äïêéìÞò

202

ÌÝèïäïò åëÝã÷ïõ

Åðéâåâáßùóç êáé Ýëåã÷ïò

Åðéâåâáßùóç éóôïñéêïý óöáëìÜôùí

Ïñïëïãßá

Ëßóôá êùäéêþí åëÝã÷ïõ

Áíôéìåôùðéóç Ðñïâëçìáôùí

206

Ïèüíç óå åíóýñìáôï ôçëå÷åéñéóôÞñéï

ÍÝïò êùäéêüò åëÝã÷ïõ

Ôýðïò êáóÝôáò êüìðáêô åêñïÞò áÝñá ìßáò êáôåýèõíóçò

ÊáèçìåñéíÞ óõíôÞñçóç

Check of Concentration Limit

EH99832901

Confirmation of Indoor Unit Setup

Indoor unit setup check sheet