– 101 –

Digital Inverter

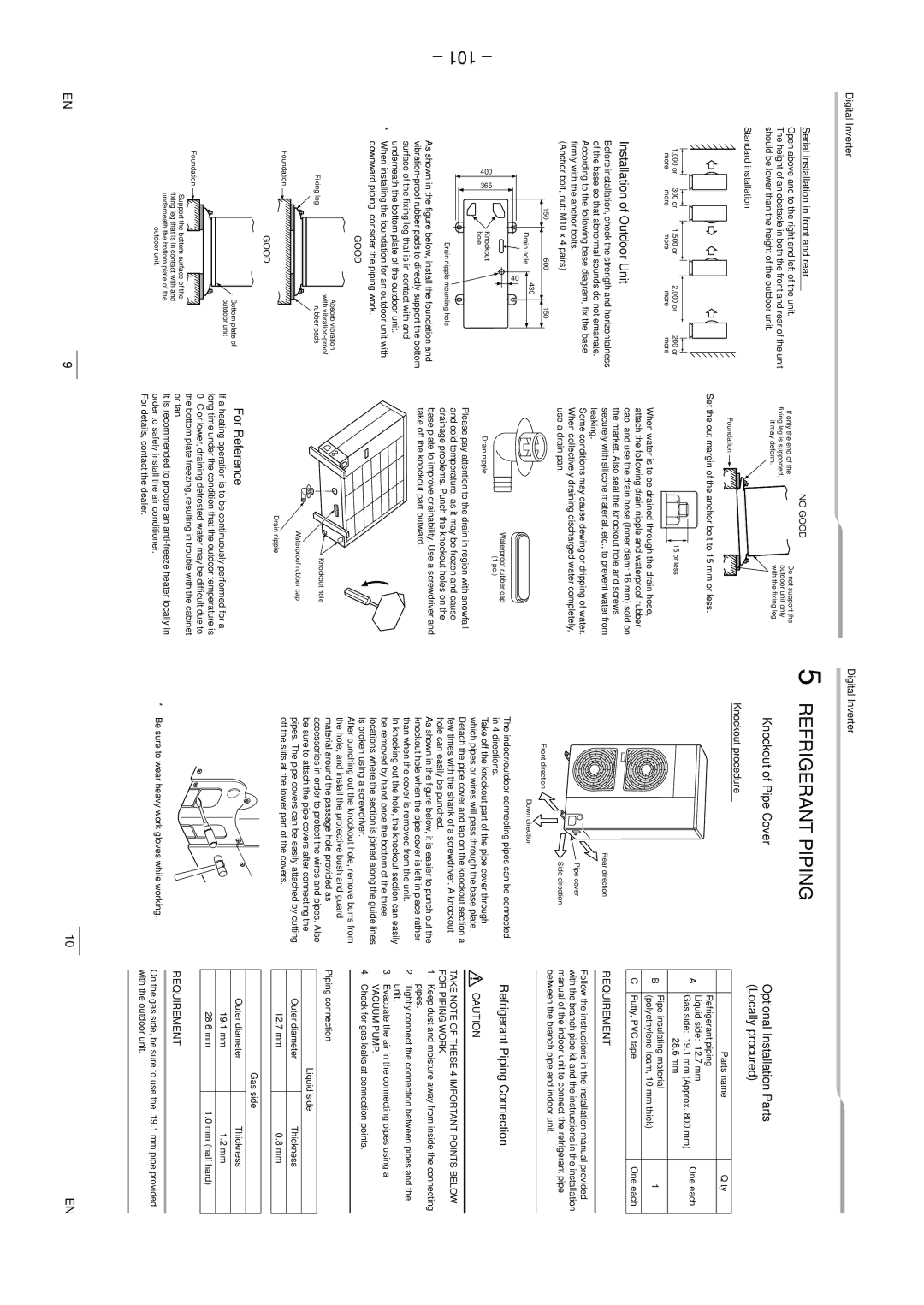

Serial installation in front and rear

Open above and to the right and left of the unit.

The height of an obstacle in both the front and rear of the unit should be lower than the height of the outdoor unit.

Standard installation

1,000 or | 300 or | 1,500 or | 2,000 or | 200 or |

more | more | more | more | more |

Installation of Outdoor Unit

•Before installation, check the strength and horizontalness of the base so that abnormal sounds do not emanate.

•According to the following base diagram, fix the base firmly with the anchor bolts.

(Anchor bolt, nut: M10 x 4 pairs)

| 150 | 600 | 150 |

|

| Drain hole | 430 |

|

|

| |

|

|

| 40 |

400 | 365 | Knockout |

|

|

| hole |

|

|

| Drain nipple mounting hole | |

•As shown in the figure below, install the foundation and

underneath the bottom plate of the outdoor unit.

*When installing the foundation for an outdoor unit with downward piping, consider the piping work.

|

|

| GOOD | |||

|

|

|

|

| Absorb vibration | |

Fixing leg |

|

|

| with | ||

|

|

|

| rubber pads | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Foundation ![]()

GOOD

Bottom plate of outdoor unit

Foundation ![]()

![]()

![]()

![]()

Support the bottom surface of the fixing leg that is in contact with and underneath the bottom plate of the outdoor unit.

| NO GOOD |

If only the end of the | Do not support the |

fixing leg is supported, | outdoor unit only |

it may deform. | with the fixing leg. |

Foundation ![]()

![]()

Set the out margin of the anchor bolt to 15 mm or less.

15 or less

•When water is to be drained through the drain hose, attach the following drain nipple and waterproof rubber cap, and use the drain hose (Inner diam: 16 mm) sold on the market. Also seal the knockout hole and screws securely with silicone material, etc., to prevent water from leaking.

Some conditions may cause dewing or dripping of water.

•When collectively draining discharged water completely, use a drain pan.

Waterproof rubber cap (1 pc.)

Drain nipple

•Please pay attention to the drain in region with snowfall and cold temperature, as it may be frozen and cause drainage problems. Punch the knockout holes on the base plate to improve drainability. Use a screwdriver and take off the knockout part outward.

![]() Knockout hole

Knockout hole

Waterproof rubber cap

Drain nipple

For Reference

If a heating operation is to be continuously performed for a long time under the condition that the outdoor temperature is 0 °C or lower, draining defrosted water may be difficult due to the bottom plate freezing, resulting in trouble with the cabinet or fan.

It is recommended to procure an

For details, contact the dealer.

Digital Inverter

5 REFRIGERANT PIPING

Knockout of Pipe Cover

Knockout procedure

Rear direction

Pipe cover

Side direction

Front direction

Down direction

•The indoor/outdoor connecting pipes can be connected in 4 directions.

Take off the knockout part of the pipe cover through which pipes or wires will pass through the base plate.

•Detach the pipe cover and tap on the knockout section a few times with the shank of a screwdriver. A knockout hole can easily be punched.

•As shown in the figure below, it is easier to punch out the knockout hole when the pipe cover is left in place rather than when the cover is removed from the unit.

In knocking out the hole, the knockout section can easily be removed by hand once the bottom of the three locations where the section is joined along the guide lines is broken using a screwdriver.

•After punching out the knockout hole, remove burrs from the hole, and install the protective bush and guard material around the passage hole provided as accessories in order to protect the wires and pipes. Also be sure to attach the pipe covers after connecting the pipes. The pipe covers can be easily attached by cutting off the slits at the lower part of the covers.

*Be sure to wear heavy work gloves while working.

Optional Installation Parts (Locally procured)

| Parts name | Q’ty | |

| Refrigerant piping |

| |

A | Liquid side: Ø12.7 mm | One each | |

Gas side: Ø19.1 mm (Approx. 800 mm) | |||

|

| ||

| Ø28.6 mm |

| |

|

|

| |

B | Pipe insulating material | 1 | |

(polyethylene foam, 10 mm thick) | |||

|

| ||

C | Putty, PVC tape | One each |

REQUIREMENT

Follow the instructions in the installation manual provided with the branch pipe kit and the instructions in the installation manual of the indoor unit to connect the refrigerant pipe between the branch pipe and indoor unit.

Refrigerant Piping Connection

CAUTION

TAKE NOTE OF THESE 4 IMPORTANT POINTS BELOW FOR PIPING WORK

1.Keep dust and moisture away from inside the connecting pipes.

2.Tightly connect the connection between pipes and the unit.

3.Evacuate the air in the connecting pipes using a

VACUUM PUMP.

4.Check for gas leaks at connection points.

Piping connection

| Liquid side | |

Outer diameter |

| Thickness |

Ø12.7 mm |

| 0.8 mm |

|

|

|

|

| |

| Gas side | |

Outer diameter |

| Thickness |

Ø19.1 mm |

| 1.2 mm |

|

|

|

Ø28.6 mm |

| 1.0 mm (half hard) |

|

|

|

REQUIREMENT

On the gas side, be sure to use the Ø19.1 mm pipe provided with the outdoor unit.

EN | 9 |

| 10 | EN |