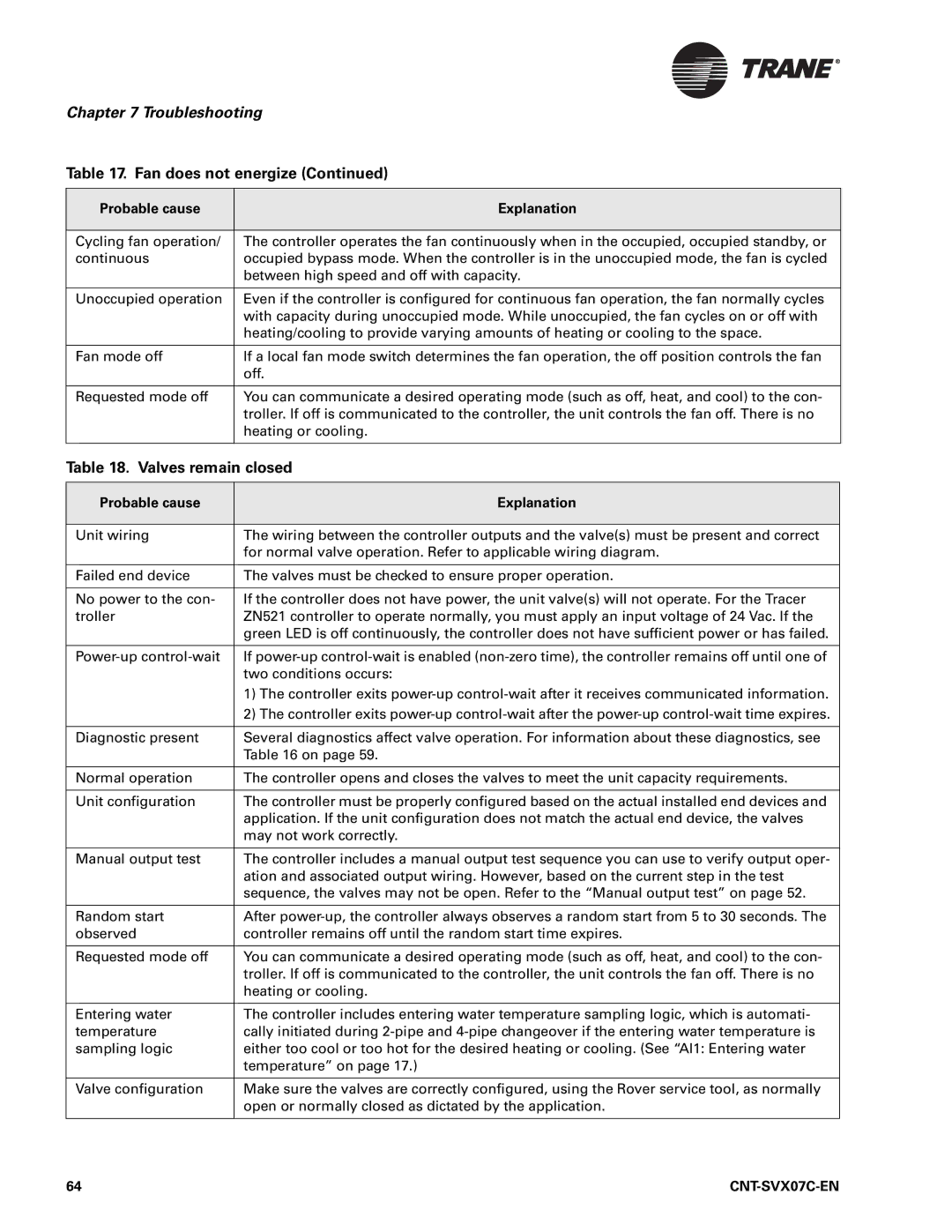

Chapter 7 Troubleshooting

Table 17. Fan does not energize (Continued)

Probable cause | Explanation |

|

|

Cycling fan operation/ | The controller operates the fan continuously when in the occupied, occupied standby, or |

continuous | occupied bypass mode. When the controller is in the unoccupied mode, the fan is cycled |

| between high speed and off with capacity. |

|

|

Unoccupied operation | Even if the controller is configured for continuous fan operation, the fan normally cycles |

| with capacity during unoccupied mode. While unoccupied, the fan cycles on or off with |

| heating/cooling to provide varying amounts of heating or cooling to the space. |

|

|

Fan mode off | If a local fan mode switch determines the fan operation, the off position controls the fan |

| off. |

|

|

Requested mode off | You can communicate a desired operating mode (such as off, heat, and cool) to the con- |

| troller. If off is communicated to the controller, the unit controls the fan off. There is no |

| heating or cooling. |

|

|

Table 18. Valves remain closed

Probable cause | Explanation |

|

|

Unit wiring | The wiring between the controller outputs and the valve(s) must be present and correct |

| for normal valve operation. Refer to applicable wiring diagram. |

|

|

Failed end device | The valves must be checked to ensure proper operation. |

|

|

No power to the con- | If the controller does not have power, the unit valve(s) will not operate. For the Tracer |

troller | ZN521 controller to operate normally, you must apply an input voltage of 24 Vac. If the |

| green LED is off continuously, the controller does not have sufficient power or has failed. |

|

|

If | |

| two conditions occurs: |

| 1) The controller exits |

| 2) The controller exits |

|

|

Diagnostic present | Several diagnostics affect valve operation. For information about these diagnostics, see |

| Table 16 on page 59. |

|

|

Normal operation | The controller opens and closes the valves to meet the unit capacity requirements. |

|

|

Unit configuration | The controller must be properly configured based on the actual installed end devices and |

| application. If the unit configuration does not match the actual end device, the valves |

| may not work correctly. |

|

|

Manual output test | The controller includes a manual output test sequence you can use to verify output oper- |

| ation and associated output wiring. However, based on the current step in the test |

| sequence, the valves may not be open. Refer to the “Manual output test” on page 52. |

|

|

Random start | After |

observed | controller remains off until the random start time expires. |

|

|

Requested mode off | You can communicate a desired operating mode (such as off, heat, and cool) to the con- |

| troller. If off is communicated to the controller, the unit controls the fan off. There is no |

| heating or cooling. |

|

|

Entering water | The controller includes entering water temperature sampling logic, which is automati- |

temperature | cally initiated during |

sampling logic | either too cool or too hot for the desired heating or cooling. (See “AI1: Entering water |

| temperature” on page 17.) |

|

|

Valve configuration | Make sure the valves are correctly configured, using the Rover service tool, as normally |

| open or normally closed as dictated by the application. |

|

|

64 |

|