MODEL C24EA - SWITCHES, BUZZER AND SOLENOIDS

C.Repeat clamping of steam outlet hose a total of three times to find the average cut- out pressure. Record pressure.

D.If pressure is outside tolerance (4.5 to 4.7 psi), adjustment is necessary. Refer to Adjustment.

E.If

8.Remove test gauge and reinstall delime cap.

Adjustment

1.Allow full steam production to stabilize. This is accomplished by allowing approximately five cycles of fill to occur once steam is being produced by the generator tank. Observe LED on water control board to count cycles.

NOTE: Make small incremental adjustments (1/8 turn of toothed adjustment wheel) when adjusting

2.Referring to

A. From looking down on pressure switch:

1)Turn adjustment wheel CCW to decrease

2)Turn adjustment wheel CW to increase

B.Check

VACUUM RELIEF SOLENOID

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

NOTE: The vacuum relief solenoid on Professional models is positioned with the solenoid coil toward the cooking chamber away from the super heater. For Basic models, the vacuum relief solenoid is positioned with the coil toward the right side of machine for easier serviceability.

1.Turn off machine to drain steam generator tank. Allow steamer to complete drain cycle.

A. Turn off water supply.

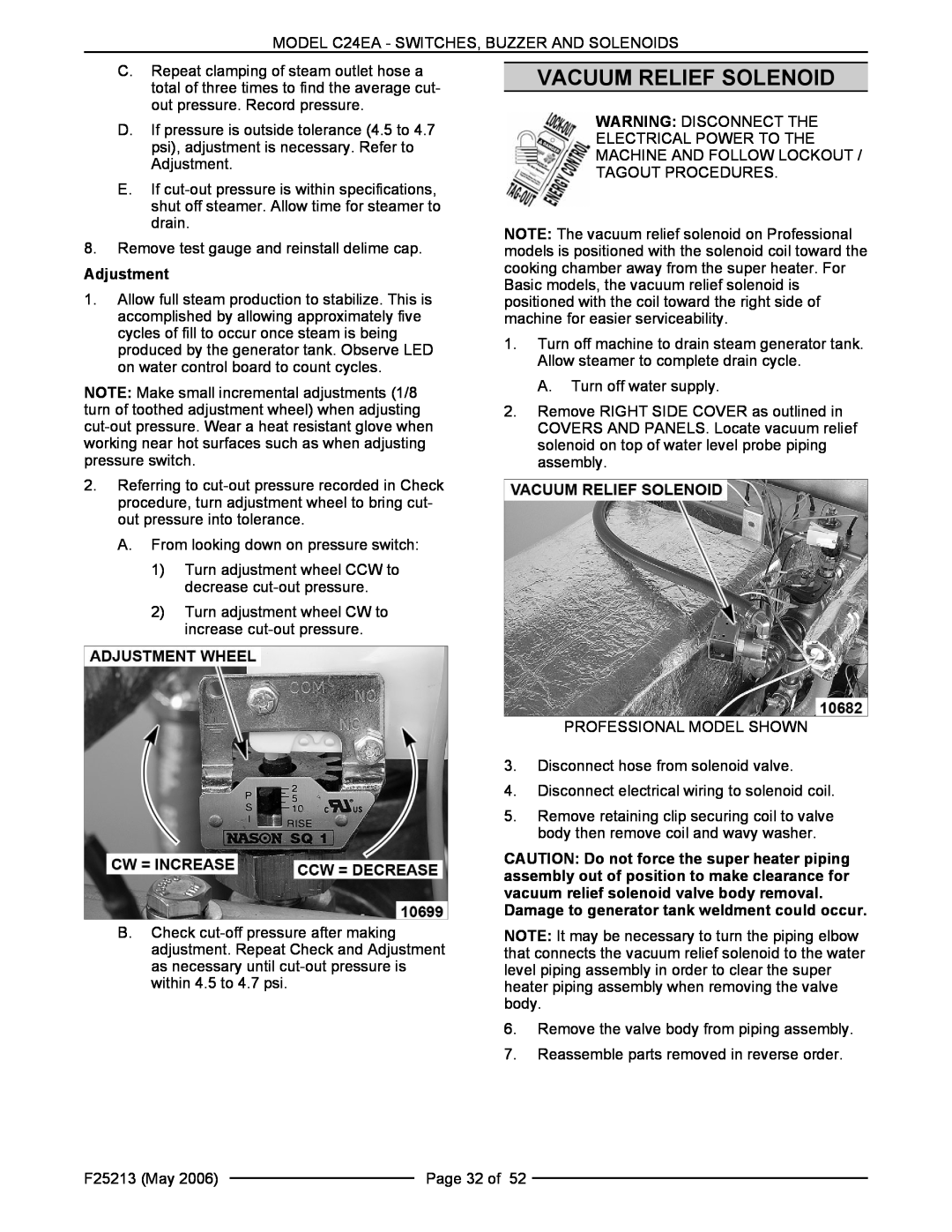

2.Remove RIGHT SIDE COVER as outlined in COVERS AND PANELS. Locate vacuum relief solenoid on top of water level probe piping assembly.

PROFESSIONAL MODEL SHOWN

3.Disconnect hose from solenoid valve.

4.Disconnect electrical wiring to solenoid coil.

5.Remove retaining clip securing coil to valve body then remove coil and wavy washer.

CAUTION: Do not force the super heater piping assembly out of position to make clearance for vacuum relief solenoid valve body removal.

Damage to generator tank weldment could occur.

NOTE: It may be necessary to turn the piping elbow that connects the vacuum relief solenoid to the water level piping assembly in order to clear the super heater piping assembly when removing the valve body.

6.Remove the valve body from piping assembly.

7.Reassemble parts removed in reverse order.

F25213 (May 2006) |

| Page 32 of 52 |

|