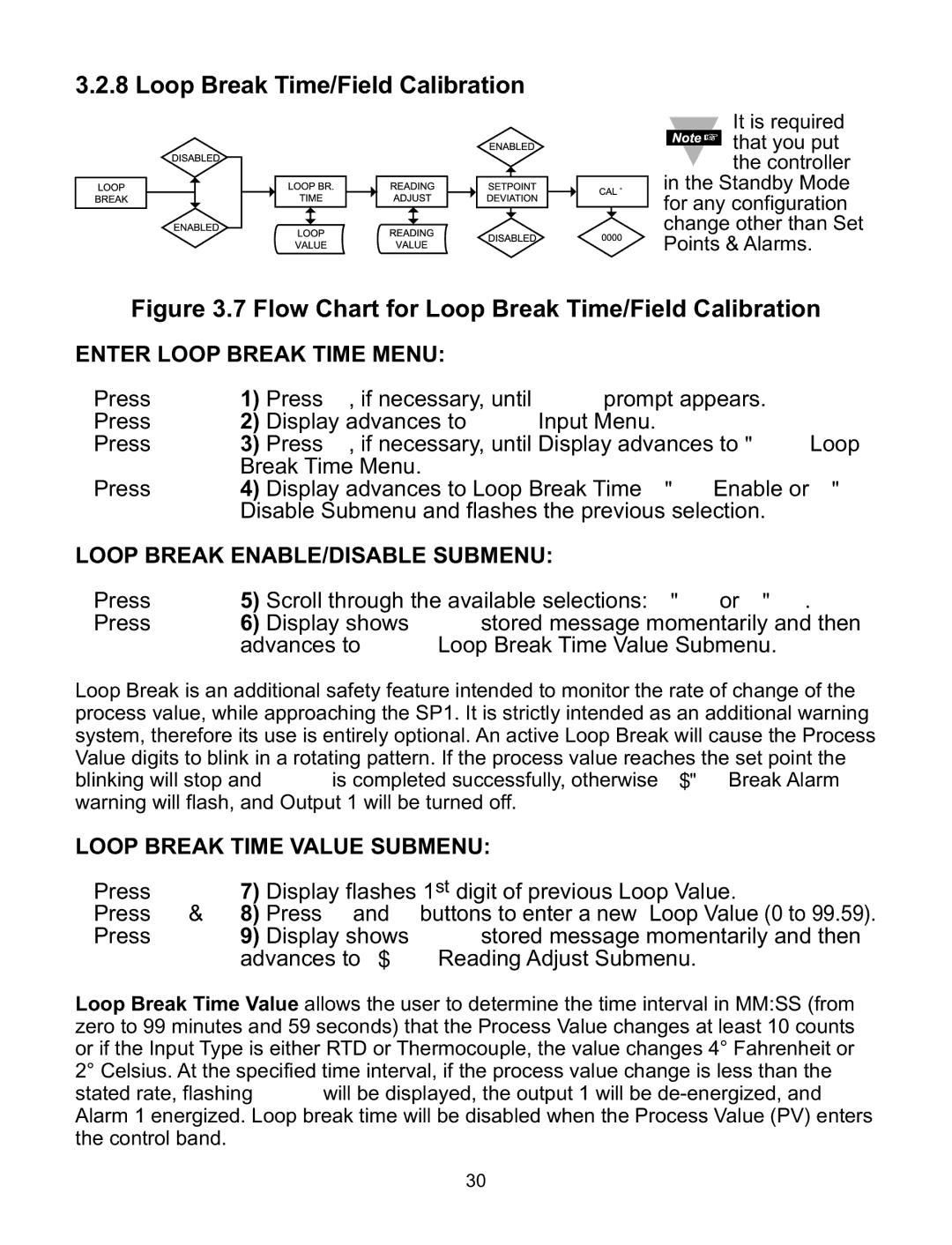

3.2.8 Loop Break Time/Field Calibration

It is required ![]() that you put the controller in the Standby Mode

that you put the controller in the Standby Mode

for any configuration change other than Set Points & Alarms.

Figure 3.7 Flow Chart for Loop Break Time/Field Calibration

ENTER LOOP BREAK TIME MENU:

Press a 1) Press a, if necessary, until CNFG prompt appears. Press d 2) Display advances to INPT Input Menu.

Press a 3) Press a, if necessary, until Display advances to LOOP Loop Break Time Menu.

Press d 4) Display advances to Loop Break Time ENBL Enable or DSBL Disable Submenu and flashes the previous selection.

LOOP BREAK ENABLE/DISABLE SUBMENU:

Press b 5) Scroll through the available selections: ENBL or DSBL. Press d 6) Display shows STRD stored message momentarily and then

advances to B.TIM Loop Break Time Value Submenu.

Loop Break is an additional safety feature intended to monitor the rate of change of the process value, while approaching the SP1. It is strictly intended as an additional warning system, therefore its use is entirely optional. An active Loop Break will cause the Process Value digits to blink in a rotating pattern. If the process value reaches the set point the blinking will stop and B.TIM is completed successfully, otherwise BR.AL Break Alarm warning will flash, and Output 1 will be turned off.

LOOP BREAK TIME VALUE SUBMENU:

Press d 7) Display flashes 1st digit of previous Loop Value.

Press b & c 8) Press b and c buttons to enter a new Loop Value (0 to 99.59). Press d 9) Display shows STRD stored message momentarily and then

advances to R.ADJ Reading Adjust Submenu.

Loop Break Time Value allows the user to determine the time interval in MM:SS (from zero to 99 minutes and 59 seconds) that the Process Value changes at least 10 counts or if the Input Type is either RTD or Thermocouple, the value changes 4° Fahrenheit or 2° Celsius. At the specified time interval, if the process value change is less than the stated rate, flashing B.TIM will be displayed, the output 1 will be

30