Placement

Positioning

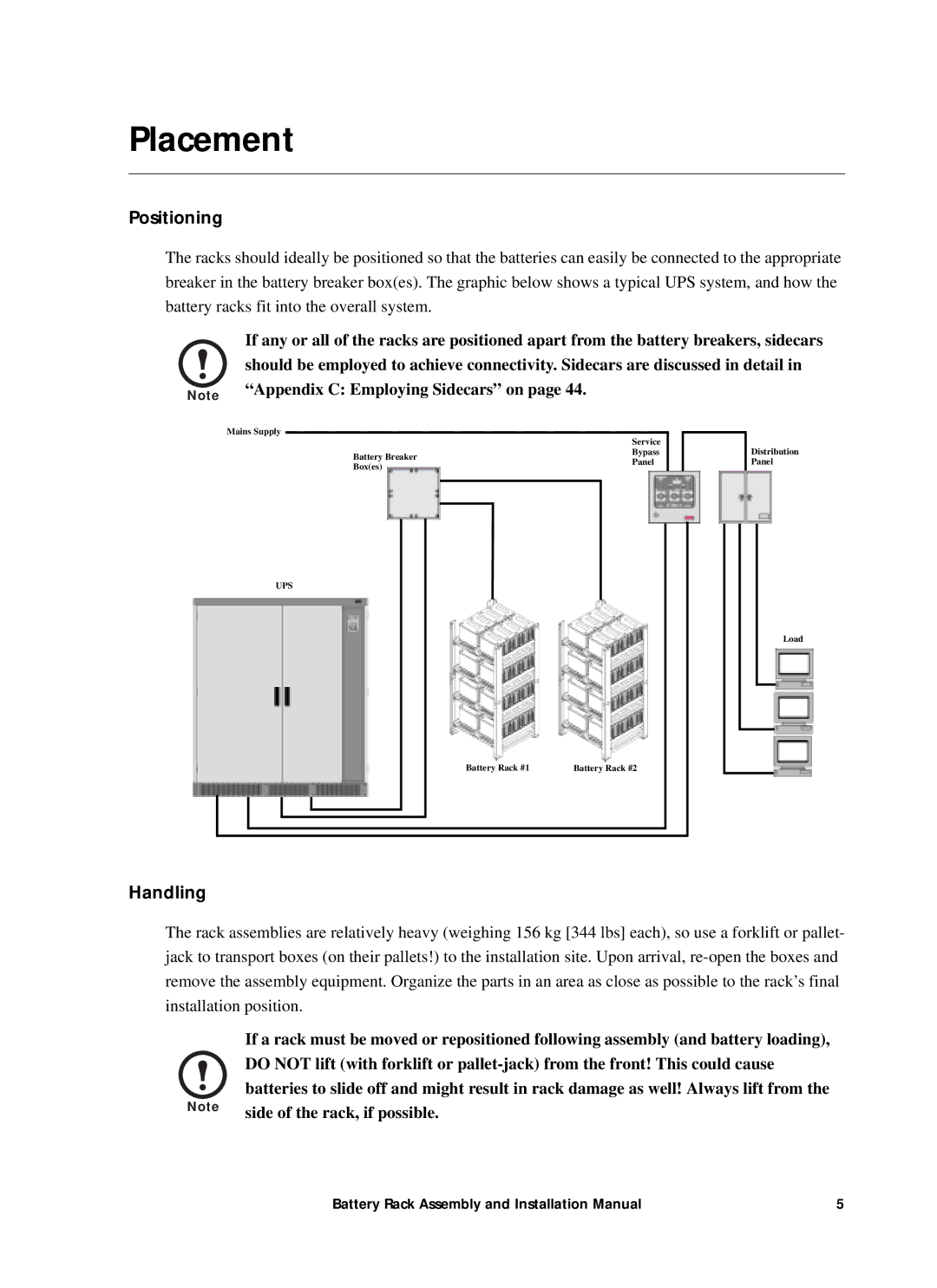

The racks should ideally be positioned so that the batteries can easily be connected to the appropriate breaker in the battery breaker box(es). The graphic below shows a typical UPS system, and how the battery racks fit into the overall system.

| If any or all of the racks are positioned apart from the battery breakers, sidecars |

| should be employed to achieve connectivity. Sidecars are discussed in detail in |

Note | “Appendix C: Employing Sidecars” on page 44. |

Mains Supply

|

| Service | |

Battery Breaker |

| Bypass | |

| Panel | ||

Box(es) |

| ||

|

|

| |

|

|

|

|

|

|

|

|

Distribution Panel

UPS

Load

Battery Rack #1 | Battery Rack #2 |

Handling

The rack assemblies are relatively heavy (weighing 156 kg [344 lbs] each), so use a forklift or pallet- jack to transport boxes (on their pallets!) to the installation site. Upon arrival,

If a rack must be moved or repositioned following assembly (and battery loading), DO NOT lift (with forklift or

Note | side of the rack, if possible. |

|

Battery Rack Assembly and Installation Manual | 5 |