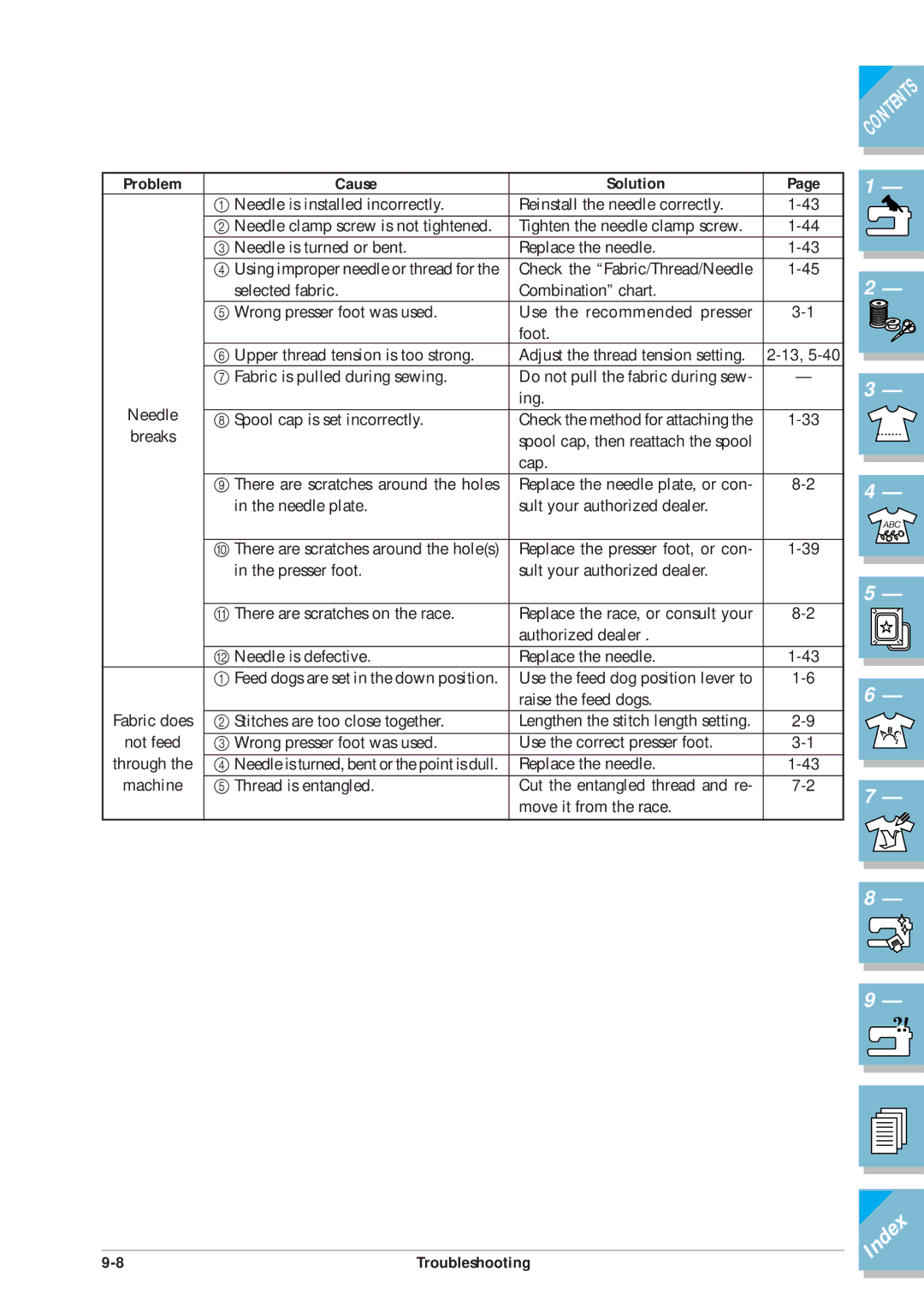

Problem | Cause | Solution | Page |

| 1 Needle is installed incorrectly. | Reinstall the needle correctly. | |

| 2 Needle clamp screw is not tightened. | Tighten the needle clamp screw. | |

| 3 Needle is turned or bent. | Replace the needle. | |

| 4 Using improper needle or thread for the | Check the “Fabric/Thread/Needle | |

| selected fabric. | Combination” chart. |

|

| 5 Wrong presser foot was used. | Use the recommended presser | |

|

| foot. |

|

| 6 Upper thread tension is too strong. | Adjust the thread tension setting. | |

| 7 Fabric is pulled during sewing. | Do not pull the fabric during sew- | — |

Needle |

| ing. |

|

8 Spool cap is set incorrectly. | Check the method for attaching the | ||

breaks |

| spool cap, then reattach the spool |

|

|

| cap. |

|

| 9 There are scratches around the holes | Replace the needle plate, or con- | |

| in the needle plate. | sult your authorized dealer. |

|

|

|

|

|

| 0 There are scratches around the hole(s) | Replace the presser foot, or con- | |

| in the presser foot. | sult your authorized dealer. |

|

|

|

|

|

| A There are scratches on the race. | Replace the race, or consult your | |

|

| authorized dealer . |

|

| B Needle is defective. | Replace the needle. | |

| 1 Feed dogs are set in the down position. | Use the feed dog position lever to | |

|

| raise the feed dogs. |

|

Fabric does | 2 Stitches are too close together. | Lengthen the stitch length setting. | |

not feed |

|

|

|

3 Wrong presser foot was used. | Use the correct presser foot. | ||

through the | 4 Needle is turned, bent or the point is dull. | Replace the needle. | |

machine | 5 Thread is entangled. | Cut the entangled thread and re- | |

|

| move it from the race. |

|

|

|

|

|

Troubleshooting |