LUBRICATION/FILTERS/FRUIDS

Element Cleaning

Use clean, dry compressed air up and down the pleats on the clean side (inside) of the element.

Continue this until the element is clean.

NOTE:

1.The paper element must be handled with care. Do not hit the element against a hard surface.

2.Air pressure at the nozzle must not exceed 689 kPa (100 PSI).

3.It may be necessary to replace the element sooner if the time interval between servicing becomes short indicating the element does not respond to cleaning (soot contaminated).

System Inspection

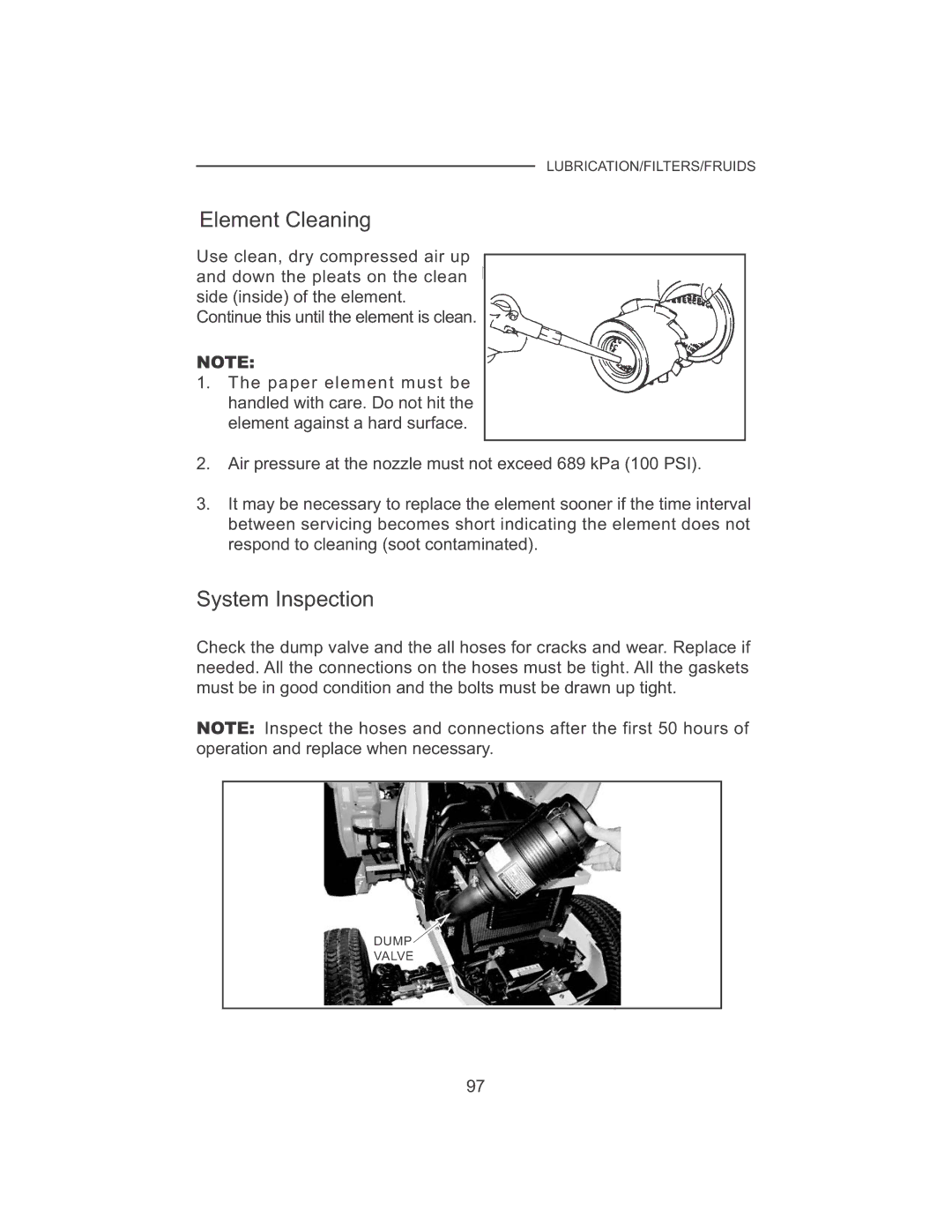

Check the dump valve and the all hoses for cracks and wear. Replace if needed. All the connections on the hoses must be tight. All the gaskets must be in good condition and the bolts must be drawn up tight.

NOTE: Inspect the hoses and connections after the first 50 hours of operation and replace when necessary.

DUMP

VALVE

97