Start-Up - 2:1 Staged Control

1. Send Unit to High Fire

Send the unit to high fire by setting the temperature selector to its maximum setting.

2. Check the High Fire

Manifold Pressure

Using a manometer, measure the burner manifold pressure at the manifold pressure test port. Refer to the Gas Train Layout in the Reference section for the test port location.

The pressure on high fire should be

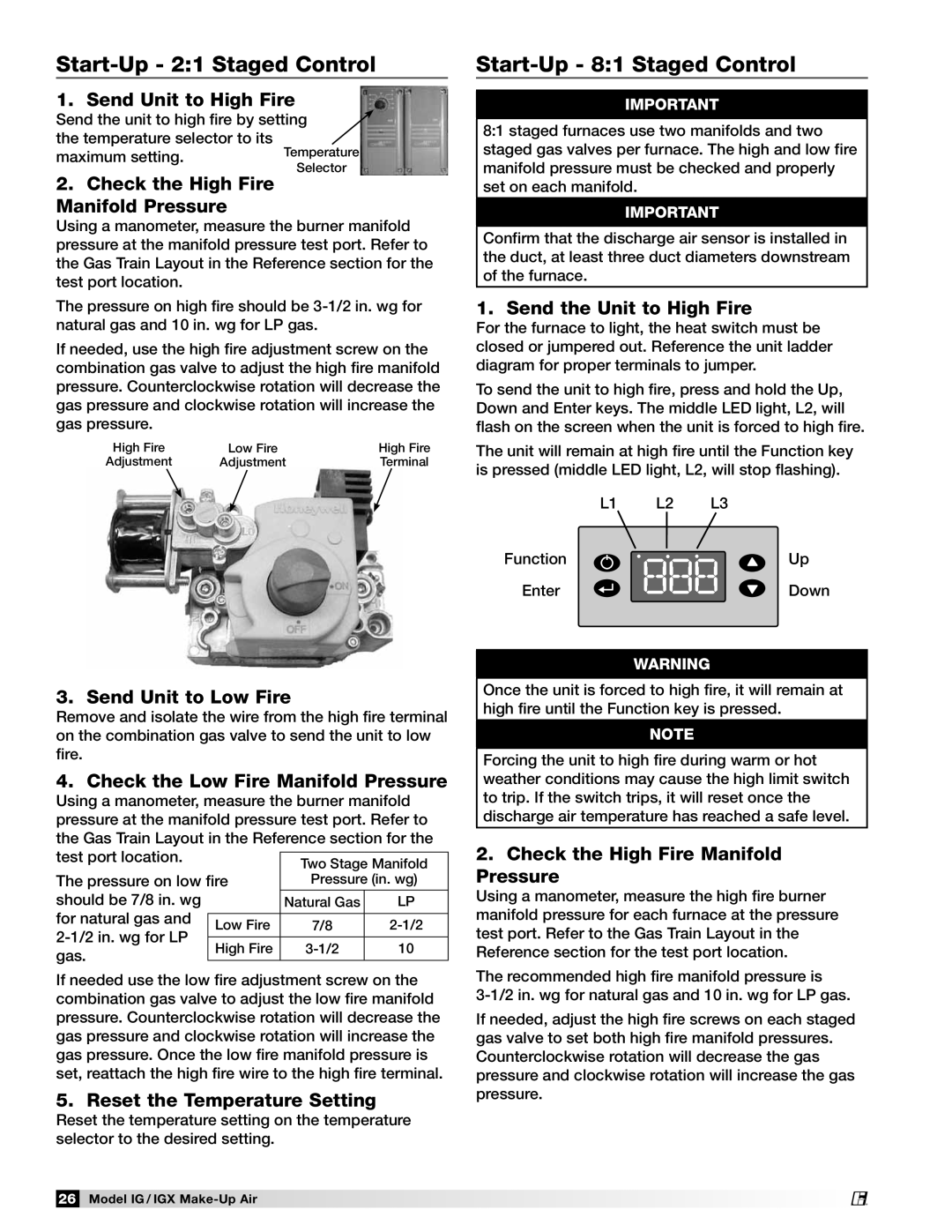

If needed, use the high fire adjustment screw on the combination gas valve to adjust the high fire manifold pressure. Counterclockwise rotation will decrease the gas pressure and clockwise rotation will increase the gas pressure.

High Fire | Low Fire | High Fire |

Adjustment | Adjustment | Terminal |

3. Send Unit to Low Fire

Remove and isolate the wire from the high fire terminal on the combination gas valve to send the unit to low fire.

4. Check the Low Fire Manifold Pressure

Using a manometer, measure the burner manifold pressure at the manifold pressure test port. Refer to

the Gas Train Layout in the Reference section for the | ||||

test port location. |

|

|

| |

| Two Stage Manifold | |||

|

| |||

The pressure on low fire | Pressure (in. wg) | |||

should be 7/8 in. wg |

| Natural Gas | LP | |

for natural gas and |

|

|

| |

Low Fire | 7/8 | |||

|

|

| ||

High Fire | 10 | |||

gas. | ||||

|

|

| ||

|

|

| ||

If needed use the low fire adjustment screw on the combination gas valve to adjust the low fire manifold pressure. Counterclockwise rotation will decrease the gas pressure and clockwise rotation will increase the gas pressure. Once the low fire manifold pressure is set, reattach the high fire wire to the high fire terminal.

5. Reset the Temperature Setting

Reset the temperature setting on the temperature selector to the desired setting.

Start-Up - 8:1 Staged Control

important

8:1 staged furnaces use two manifolds and two staged gas valves per furnace. The high and low fire manifold pressure must be checked and properly set on each manifold.

important

Confirm that the discharge air sensor is installed in the duct, at least three duct diameters downstream of the furnace.

1. Send the Unit to High Fire

For the furnace to light, the heat switch must be closed or jumpered out. Reference the unit ladder diagram for proper terminals to jumper.

To send the unit to high fire, press and hold the Up, Down and Enter keys. The middle LED light, L2, will flash on the screen when the unit is forced to high fire.

The unit will remain at high fire until the Function key is pressed (middle LED light, L2, will stop flashing).

L1 L2 L3

Function | Up |

Enter | Down |

Warning

Once the unit is forced to high fire, it will remain at high fire until the Function key is pressed.

note

Forcing the unit to high fire during warm or hot weather conditions may cause the high limit switch to trip. If the switch trips, it will reset once the discharge air temperature has reached a safe level.

2.Check the High Fire Manifold Pressure

Using a manometer, measure the high fire burner manifold pressure for each furnace at the pressure test port. Refer to the Gas Train Layout in the Reference section for the test port location.

The recommended high fire manifold pressure is

If needed, adjust the high fire screws on each staged gas valve to set both high fire manifold pressures. Counterclockwise rotation will decrease the gas pressure and clockwise rotation will increase the gas pressure.

26 Model IG / IGX

®