Program Revision Number

To access the program revision number from the default display, press the Up or Down key until the display reads F##, J## or I##. The two numbers following the letter indicate the revision number. For example, F12 indicates program F, revision twelve.

Optional Room Override (ROt)

When the room override function is triggered, the discharge air temperature (70ºF default) is temporarily changed to the room override setting (90ºF default). When the room override function is released the discharge air temperature returns to the default temperature.

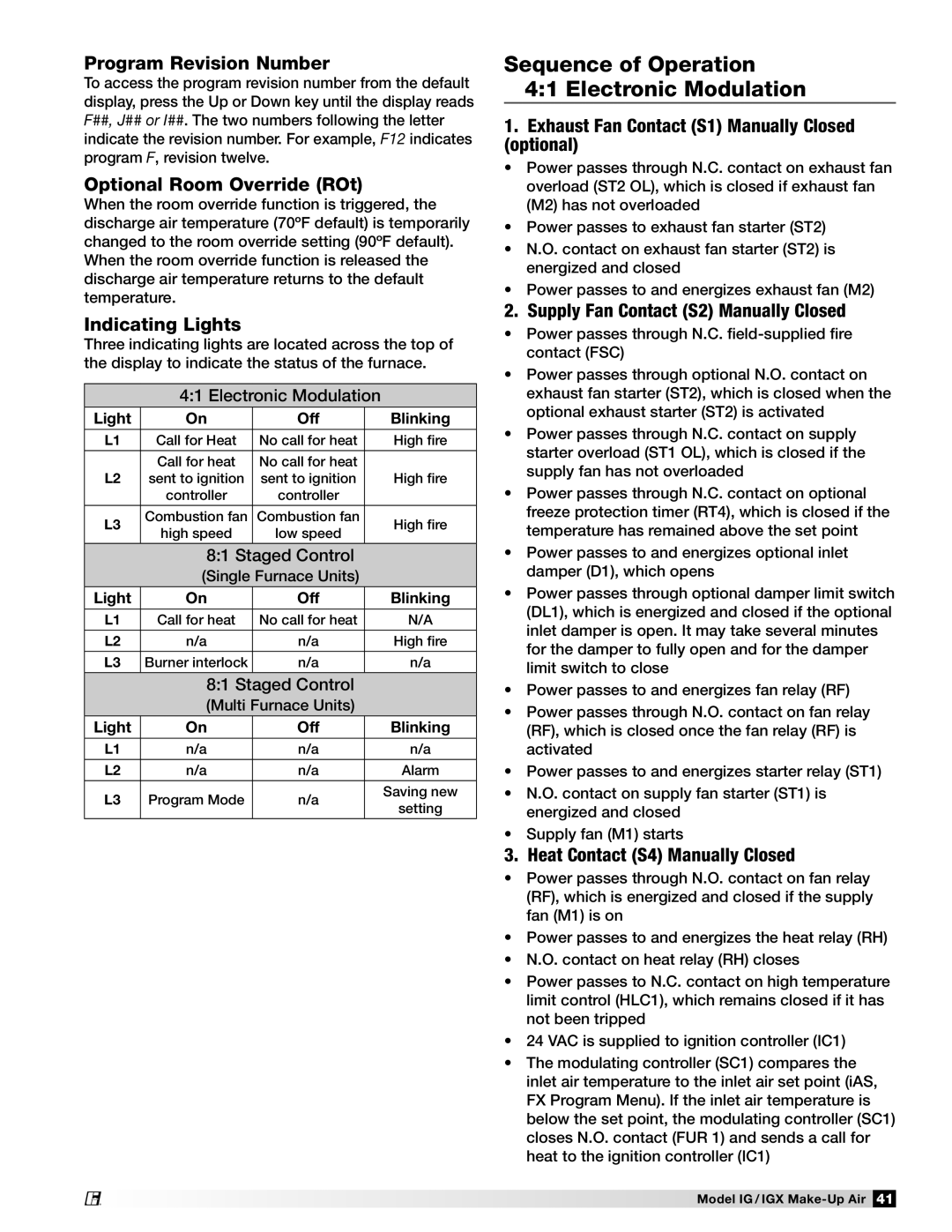

Indicating Lights

Three indicating lights are located across the top of the display to indicate the status of the furnace.

4:1 Electronic Modulation

Light | On | Off | Blinking | |

|

|

|

| |

L1 | Call for Heat | No call for heat | High fire | |

|

|

|

| |

| Call for heat | No call for heat |

| |

L2 | sent to ignition | sent to ignition | High fire | |

| controller | controller |

| |

|

|

|

| |

L3 | Combustion fan | Combustion fan | High fire | |

high speed | low speed | |||

|

| |||

|

|

|

| |

| 8:1 Staged Control |

| ||

| (Single Furnace Units) |

| ||

|

|

|

| |

Light | On | Off | Blinking | |

|

|

|

| |

L1 | Call for heat | No call for heat | N/A | |

|

|

|

| |

L2 | n/a | n/a | High fire | |

|

|

|

| |

L3 | Burner interlock | n/a | n/a | |

|

|

|

| |

| 8:1 Staged Control |

| ||

| (Multi Furnace Units) |

| ||

Light | On | Off | Blinking | |

L1 | n/a | n/a | n/a | |

|

|

|

| |

L2 | n/a | n/a | Alarm | |

|

|

|

| |

L3 | Program Mode | n/a | Saving new | |

setting | ||||

|

|

| ||

|

|

|

| |

®

Sequence of Operation 4:1 Electronic Modulation

1.Exhaust Fan Contact (S1) Manually Closed (optional)

•Power passes through N.C. contact on exhaust fan overload (ST2 OL), which is closed if exhaust fan (M2) has not overloaded

•Power passes to exhaust fan starter (ST2)

•N.O. contact on exhaust fan starter (ST2) is energized and closed

•Power passes to and energizes exhaust fan (M2)

2. Supply Fan Contact (S2) Manually Closed

•Power passes through N.C.

•Power passes through optional N.O. contact on exhaust fan starter (ST2), which is closed when the optional exhaust starter (ST2) is activated

•Power passes through N.C. contact on supply starter overload (ST1 OL), which is closed if the supply fan has not overloaded

•Power passes through N.C. contact on optional freeze protection timer (RT4), which is closed if the temperature has remained above the set point

•Power passes to and energizes optional inlet damper (D1), which opens

•Power passes through optional damper limit switch

(DL1), which is energized and closed if the optional inlet damper is open. It may take several minutes for the damper to fully open and for the damper limit switch to close

•Power passes to and energizes fan relay (RF)

•Power passes through N.O. contact on fan relay

(RF), which is closed once the fan relay (RF) is activated

•Power passes to and energizes starter relay (ST1)

•N.O. contact on supply fan starter (ST1) is energized and closed

•Supply fan (M1) starts

3. Heat Contact (S4) Manually Closed

•Power passes through N.O. contact on fan relay

(RF), which is energized and closed if the supply fan (M1) is on

•Power passes to and energizes the heat relay (RH)

•N.O. contact on heat relay (RH) closes

•Power passes to N.C. contact on high temperature limit control (HLC1), which remains closed if it has not been tripped

•24 VAC is supplied to ignition controller (IC1)

•The modulating controller (SC1) compares the inlet air temperature to the inlet air set point (iAS, FX Program Menu). If the inlet air temperature is below the set point, the modulating controller (SC1) closes N.O. contact (FUR 1) and sends a call for heat to the ignition controller (IC1)

Model IG / IGX