Motors

Motor maintenance is generally limited to cleaning and lubrication (where applicable).

Cleaning should be limited to exterior surfaces only. Removing dust and grease

Motors supplied with grease fittings should be greased in accordance with the manufacturer’s recommendations.

important

Do not allow water or solvents to enter the motor or bearings. Motors and bearings should never be sprayed with steam, water or solvents.

important

Greasing motors is only intended when fittings are provided. Many motors are permanently lubricated, requiring no additional lubrication.

Filters

Filter maintenance is generally limited to cleaning and replacement.

If aluminum mesh filters are installed, they can be washed in warm soapy water.

An adhesive spray can be added to aluminum mesh filters to increase their efficiency.

If disposable filters are installed, they can be checked by holding up to a light source. If light cannot pass through the filter, it should be replaced.

IMPORTANT

When reinstalling filters, be sure to install them with the airflow in the correct direction. An airflow direction arrow is located on the side of the filters.

IMPORTANT

Replacement filters should be from the same manufacturer and the same size as the original filters provided with the unit.

Chilled Water Coils

Test the circulating fluid for sediment, corrosive products and biological contaminants. Make the necessary corrective measures.

Maintain adequate fluid velocities and proper filtering of the fluid.

If automatic air vents are not utilized, periodic venting of the coil is recommended to remove accumulated air.

Evaporative Coolers

The media should be periodically brushed lightly with a soft bristle brush in an up and down motion while flushing with water. This aids in reducing the amount of mineral

For large amounts of mineral

The cooling media has a useful life of 3 to 5 years depending on the water quality and the

important

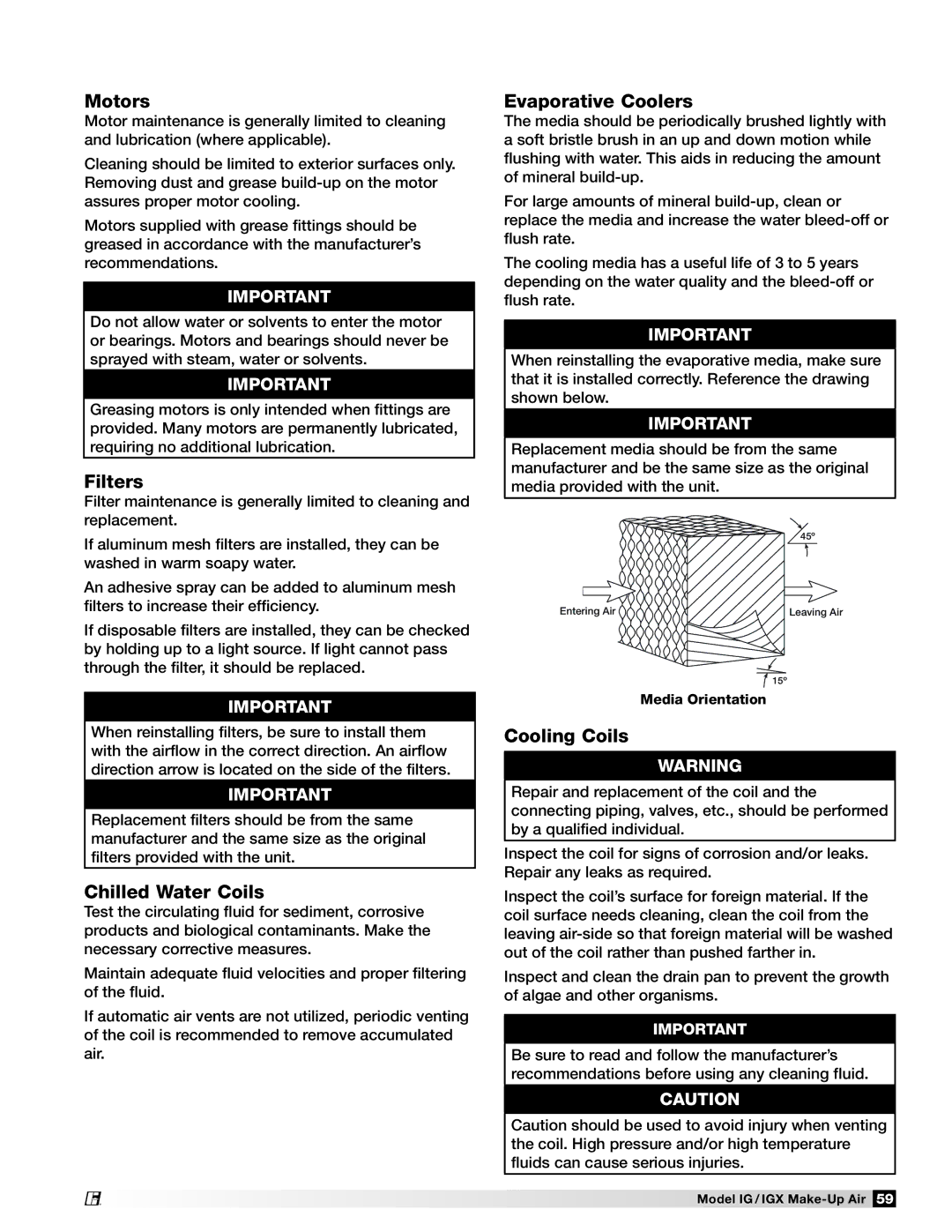

When reinstalling the evaporative media, make sure that it is installed correctly. Reference the drawing shown below.

important

Replacement media should be from the same manufacturer and be the same size as the original media provided with the unit.

45º

Entering Air | Leaving Air |

15º

Media Orientation

Cooling Coils

warning

Repair and replacement of the coil and the connecting piping, valves, etc., should be performed by a qualified individual.

Inspect the coil for signs of corrosion and/or leaks. Repair any leaks as required.

Inspect the coil’s surface for foreign material. If the coil surface needs cleaning, clean the coil from the leaving

Inspect and clean the drain pan to prevent the growth of algae and other organisms.

important

Be sure to read and follow the manufacturer’s recommendations before using any cleaning fluid.

caution

Caution should be used to avoid injury when venting the coil. High pressure and/or high temperature fluids can cause serious injuries.

®

Model IG / IGX