Start-Up - 4:1 Electronic Modulation

1. Send the Unit to High Fire

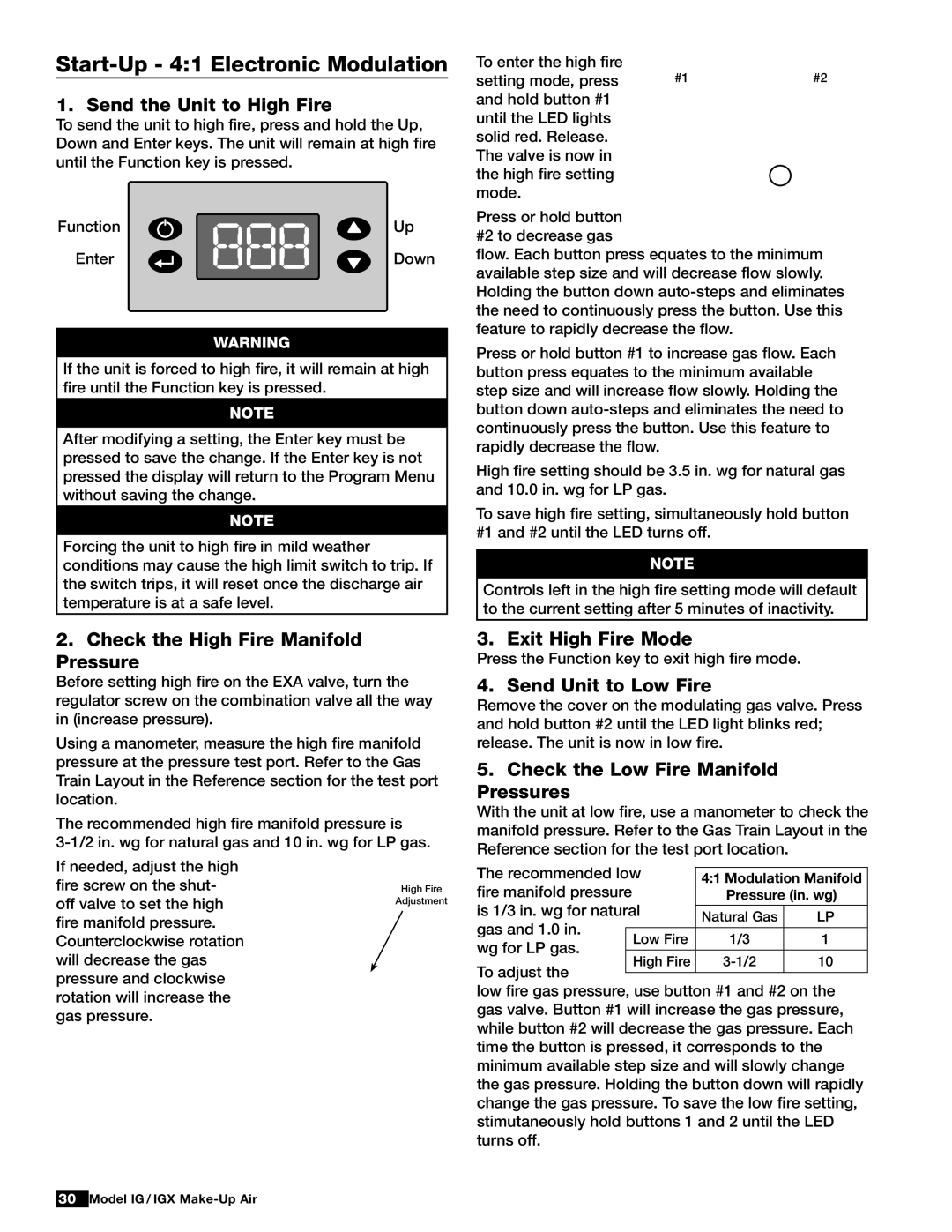

To send the unit to high fire, press and hold the Up, Down and Enter keys. The unit will remain at high fire until the Function key is pressed.

Function | Up |

Enter | Down |

Warning

If the unit is forced to high fire, it will remain at high fire until the Function key is pressed.

note

After modifying a setting, the Enter key must be pressed to save the change. If the Enter key is not pressed the display will return to the Program Menu without saving the change.

note

Forcing the unit to high fire in mild weather conditions may cause the high limit switch to trip. If the switch trips, it will reset once the discharge air temperature is at a safe level.

2.Check the High Fire Manifold Pressure

Before setting high fire on the EXA valve, turn the regulator screw on the combination valve all the way in (increase pressure).

Using a manometer, measure the high fire manifold pressure at the pressure test port. Refer to the Gas Train Layout in the Reference section for the test port location.

The recommended high fire manifold pressure is

To enter the high fire | #1 | #2 |

setting mode, press | ||

and hold button #1 |

|

|

until the LED lights |

|

|

solid red. Release. |

|

|

The valve is now in |

| LED |

the high fire setting |

| |

mode. |

| Light |

|

|

Press or hold button #2 to decrease gas

flow. Each button press equates to the minimum available step size and will decrease flow slowly. Holding the button down

Press or hold button #1 to increase gas flow. Each button press equates to the minimum available step size and will increase flow slowly. Holding the button down

High fire setting should be 3.5 in. wg for natural gas and 10.0 in. wg for LP gas.

To save high fire setting, simultaneously hold button #1 and #2 until the LED turns off.

note

Controls left in the high fire setting mode will default to the current setting after 5 minutes of inactivity.

3. Exit High Fire Mode

Press the Function key to exit high fire mode.

4. Send Unit to Low Fire

Remove the cover on the modulating gas valve. Press and hold button #2 until the LED light blinks red; release. The unit is now in low fire.

5.Check the Low Fire Manifold Pressures

With the unit at low fire, use a manometer to check the manifold pressure. Refer to the Gas Train Layout in the Reference section for the test port location.

If needed, adjust the high fire screw on theshut- off valve to set the high fire manifold pressure. Counterclockwise rotation will decrease the gas pressure and clockwise rotation will increase the gas pressure.

High Fire

Adjustment

The recommended low |

|

| ||

4:1 Modulation Manifold | ||||

fire manifold pressure | Pressure (in. wg) | |||

is 1/3 in. wg for natural |

|

| ||

Natural Gas | LP | |||

gas and 1.0 in. |

| |||

|

|

| ||

wg for LP gas. | Low Fire | 1/3 | 1 | |

|

|

| ||

High Fire | 10 | |||

To adjust the | ||||

|

|

| ||

low fire gas pressure, use button #1 and #2 on the gas valve. Button #1 will increase the gas pressure, while button #2 will decrease the gas pressure. Each time the button is pressed, it corresponds to the minimum available step size and will slowly change the gas pressure. Holding the button down will rapidly change the gas pressure. To save the low fire setting, stimutaneously hold buttons 1 and 2 until the LED turns off.

30Model IG / IGX

®